Dalam industri permesinan konstruksi, komponen undercarriage ekskavator dan buldoser menghadapi kondisi kerja ekstrem dan beban yang sangat besar. Sebagai komponen inti dari komponen undercarriage, rantai track dan perakitan tautan trek memiliki persyaratan yang sangat tinggi untuk sifat material. 35MnBH dan 40Mn2 adalah dua baja paduan umum yang banyak digunakan dalam bagian sasis ekskavator.

Analisis material baja 35MnBH

35MnBH adalah baja paduan rendah berkekuatan tinggi, komponen utamanya meliputi:

| Elemen | Rentang Konten |

| Karbon (C): | 0.32% – 0.40% |

| Mangan (Mn): | 1.20% – 1.60% |

| Silikon (Si): | 0.15% – 0.35% |

| Boron (B): | 0.001% – 0.005% |

Fitur-fiturnya meliputi:

- Kekuatan tinggi dan ketahanan aus yang tinggi: Karena penambahan boron, 35MnBH memiliki kemampuan pengerasan yang sangat baik, yang secara signifikan meningkatkan kekerasan dan ketahanan aus material.

- Kemampuan mesin yang baik: Meskipun kekerasannya tinggi, 35MnBH masih memiliki kinerja pemotongan dan pengelasan yang baik.

- Tahan benturan kuat: Cocok digunakan pada kondisi beban benturan tinggi.

Analisis material baja 40Mn2

40Mn2 adalah baja paduan karbon sedang umum lainnya, dan komponen utamanya adalah:

| Elemen | Rentang Konten |

| Karbon (C): | 0.37% – 0.45% |

| Mangan (Mn): | 1.20% – 1.60% |

| Silikon (Si): | 0.15% – 0.35% |

Karakteristiknya meliputi:

- Ketangguhan dan kekuatan tinggi: Kandungan mangan yang tinggi membuat 40Mn2 memiliki kekuatan dan ketangguhan yang lebih tinggi.

- Kemampuan pengerasan yang baik: Setelah pendinginan dan temper, 40Mn2 dapat memperoleh sifat mekanik komprehensif yang sangat baik.

- Ketahanan korosi: Dibandingkan dengan baja karbon biasa, 40Mn2 memiliki ketahanan korosi yang lebih baik.

Perbedaan utama antara 35MnBH dan 40Mn2

Kekerasan dan ketangguhan:

- Karena adanya boron, 35MnBH memiliki kekerasan dan ketahanan aus yang lebih kuat, yang cocok untuk aplikasi keausan tinggi.

- 40Mn2 memiliki ketangguhan lebih tinggi dan dapat menahan beban benturan lebih baik.

Ketahanan aus:

- 35MnBH lebih unggul daripada 40Mn2 dan lebih cocok untuk bagian yang harus bersentuhan dengan tanah keras untuk waktu lama.

Lingkungan yang berlaku:

- 35MnBH cocok untuk lingkungan dengan keausan tinggi dan beban tinggi, seperti pertambangan.

- 40Mn2 lebih cocok untuk aplikasi beban sedang yang memerlukan ketangguhan tertentu, seperti pekerjaan tanah.

Aplikasi dalam perakitan rantai lintasan dan tautan lintasan

Rantai lintasan:

- 35MnBH: Karena ketahanan aus dan kekerasannya yang tinggi, 35MnBH sangat cocok sebagai bahan utama rantai perayap, yang secara signifikan dapat meningkatkan masa pakai rantai, terutama di lingkungan yang keras.

- 40Mn2: Ketangguhannya yang tinggi membuatnya cocok untuk komponen rantai yang harus menahan gaya benturan tinggi, yang dapat mengurangi risiko putusnya rantai.

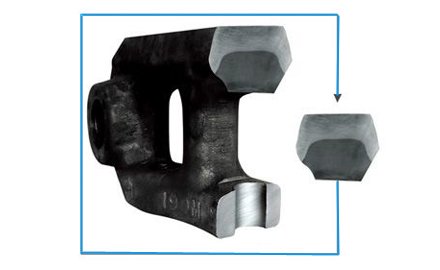

Perakitan trek:

- 35MnBH: Pada perakitan perayap, komponen utama seperti tautan lintasan dan pin biasanya menggunakan 35MnBH untuk meningkatkan ketahanan aus.

- 40Mn2: Cocok untuk komponen yang memerlukan ketangguhan ekstra, seperti sproket penahan beban atau roda penggerak.

Keunggulan kedua bahan tersebut

Keunggulan 35MnBH:

- Ketahanan aus yang tinggi cocok untuk kondisi kerja keras dan mengurangi frekuensi penggantian.

- Kinerja pemrosesan yang sangat baik, cocok untuk berbagai kebutuhan manufaktur.

Keuntungan 40Mn2:

- Ketangguhan lebih tinggi, dapat menahan beban benturan lebih besar.

- Ketahanan korosi yang baik, cocok untuk lingkungan lembab.

Lingkungan aplikasi yang sesuai

Lingkungan yang berlaku untuk 35MnBH:

- Daerah dengan tingkat keausan dan benturan tinggi seperti pertambangan dan penggalian.

- Proyek teknik di gurun atau kondisi suhu ekstrem.

Lingkungan yang berlaku untuk 40Mn2:

- Lingkungan konstruksi dengan beban sedang dan kelembaban tinggi.

- Skenario aplikasi untuk pekerjaan tanah atau mesin ringan.

Solusi perakitan trek disediakan oleh GFM

Sebagai seorang profesional produsen suku cadang undercarriage GFM menyediakan rantai rel dan rakitan rel yang dapat terbuat dari baja 35MnBH atau 40Mn2. Keunggulan spesifiknya meliputi:

- Layanan yang disesuaikan: memilih bahan dan skema desain yang paling sesuai dengan kebutuhan pelanggan.

- Kontrol kualitas yang ketat: Setiap kumpulan bahan menjalani analisis komposisi kimia dan pengujian sifat mekanis yang ketat untuk memastikan kinerja produk yang andal.

- Kinerja biaya tinggi: harga yang kompetitif disediakan melalui proses produksi yang dioptimalkan.

Baik 35MnBH yang sangat tahan aus dan 40Mn2 yang sangat kuat memainkan peran yang tak tergantikan dalam bagian undercarriage excavatorDengan pengalaman manufaktur yang kaya dan kemampuan Litbang yang kuat, GFM dapat menyediakan rantai track dan rakitan track yang memenuhi berbagai skenario aplikasi kepada pelanggan. Jika Anda mencari solusi undercarriage berkinerja tinggi dan tahan lama, silakan pilih GFM.

Hubungi kami: Untuk informasi lebih lanjut dan detail produk tentang baja 35MnBH dan 40Mn2, silakan kunjungi situs web resmi kami atau hubungi kami langsung!

| Dapatkan penawaran cepat dan gratis | Surel: henry@gfmparts.com | WhatsApp: +86 17705953659 |