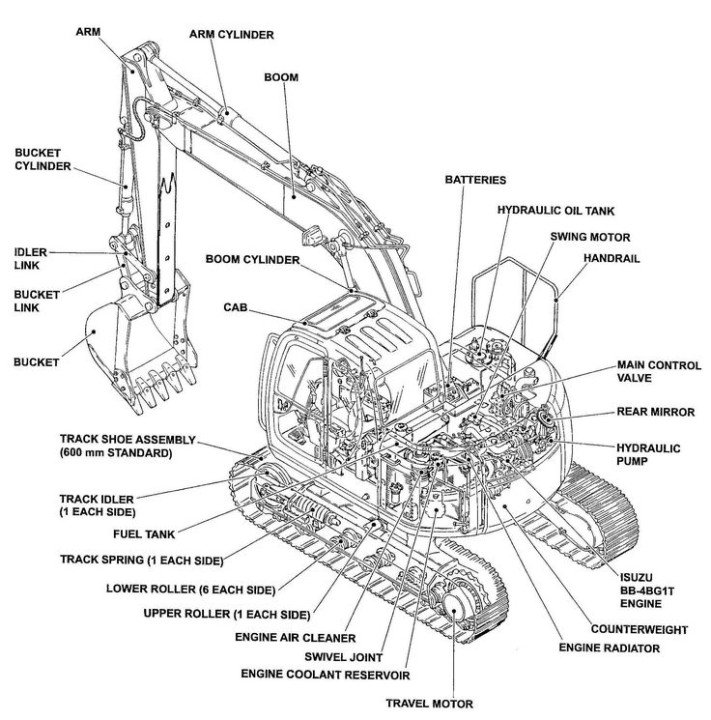

As the core machinery in the modern construction industry, excavators carry a large number of operating tasks. In the chassis system of the excavator, the sprocket plays a vital role. It realizes the driving and load-bearing functions of the machine by combining with the track plate. However, under long-term high-load working conditions, the frequent use of excavator sprockets leads to various problems. If they are not repaired and maintained in time, the overall performance and life of the excavator will be seriously affected. Therefore, understanding the solutions and preventive measures for common sprocket problems is crucial to ensure the stable operation of the excavator.

Common problems with excavator sprockets

Sprocket wear

The teeth of the sprocket may wear during the process of continuous contact and friction with the track shoe. The main manifestation of wear is that the surface of the teeth gradually becomes smooth, resulting in the meshing between the sprocket and the track shoe is no longer accurate, reducing the driving force and work efficiency. Especially in high-intensity construction environments, the wear of the sprocket is particularly serious.

Wear manifestations:

- The edges and corners of the teeth become blunt, resulting in loose meshing.

- There are obvious scratches and gaps on the surface.

- There is a gap at the joint between the sprocket and the track, affecting the stability of the machine.

Sprocket deformation

The sprocket may deform under long-term load, especially when subjected to large impact forces. Sprocket deformation will cause uneven meshing between the gear and the track shoe, increase the friction of the sprocket, and may eventually cause further damage to the sprocket.

Deformation manifestations:

- The teeth of the sprocket are bent or twisted.

- The overall profile of the sprocket is no longer smooth, affecting the normal rotation of the sprocket.

- The excavator has obvious shaking or instability when driving.

Loose sprocket

If the installation connection part of the sprocket is not checked for a long time, the bolts or pins may loosen, resulting in a loose connection between the sprocket and the drive shaft. A loose sprocket will not only lead to a decrease in work efficiency, but may also cause more serious mechanical failures, and even safety hazards such as sprocket shedding.

Loose manifestations:

- The sprocket has unstable movement or shaking.

- Abnormal gap appears at the connection between the sprocket and the drive shaft.

- There is an abnormal shaking feeling when the excavator is driving.

Abnormal sprocket noise

When the sprocket is running normally, it should be stable. If you hear abnormal noise during driving, especially the sound of metal collision, this is usually a warning of a problem with the sprocket. The appearance of noise may be caused by tooth wear or insufficient lubrication. Long-term non-treatment will cause the sprocket to be damaged more.

Noise manifestations:

- Harsh metal friction sound.

- Sprocket makes a creaking or knocking sound when running.

- The noise increases or decreases with the speed of the excavator.

Cause Analysis of Excavator Sprocket Problems

Improper Operation

Improper operation is a common cause of sprocket failure. For example, if the operator does not operate according to the workload specified by the equipment, frequent sudden acceleration, sudden braking or too fast steering will put additional pressure on the sprocket, causing it to wear or deform early.

Common improper operations:

- Frequent sudden braking and acceleration.

- Overload work.

- Operating on uneven or rugged ground.

Environmental factors

The working environment also has a significant impact on the service life of the sprocket. Environmental factors such as high temperature, humidity, and dust will accelerate the wear of the sprocket. Especially in a dusty environment, dust and sand will enter the sprocket teeth, causing additional wear and damage.

Environmental impact:

- High temperature causes lubricating oil to lose and increase friction.

- Sand in a dusty environment abrades the sprocket.

- Wet environment causes corrosion on the sprocket surface.

Material issues

The quality of the sprocket directly determines its wear resistance and service life. If the sprocket material is not up to standard or the manufacturing process is not qualified, the sprocket may not be able to withstand high-intensity loads, resulting in early damage.

Common problems:

- The casting process is not fine, and defects are prone to occur in the sprocket teeth.

- Insufficient material hardness leads to poor wear resistance.

- The material has poor corrosion resistance and is prone to rust in a humid environment.

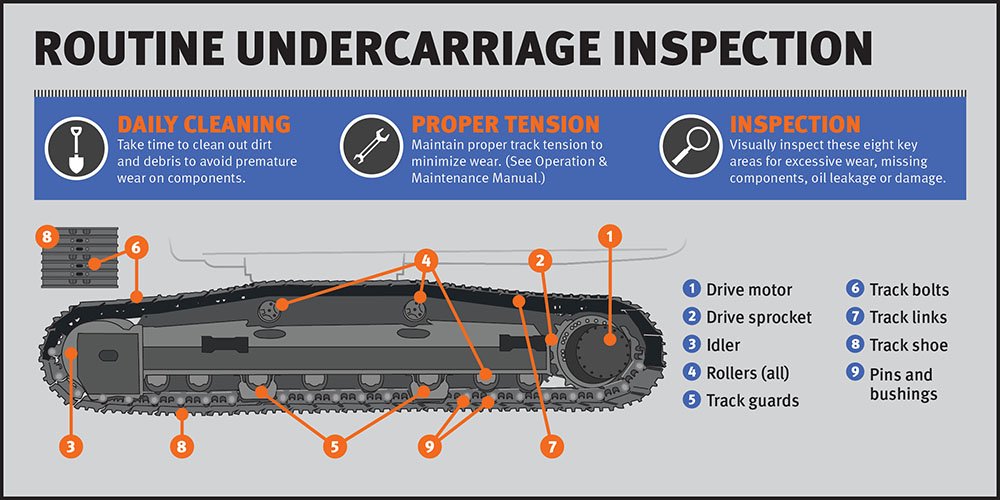

Inadequate maintenance

Daily maintenance of the sprocket is essential to extend its service life. If the lubricating oil is not replaced and the sprocket surface is not cleaned on time, dirt may accumulate inside the sprocket, resulting in increased friction and increased wear.

Consequences of insufficient maintenance:

- Dirt accumulates on the sprocket surface, affecting the lubrication effect.

- The lubricating oil is not replaced in time, resulting in lack of lubrication on the teeth.

- Failure to check the wear of the sprocket in time causes the sprocket to be scrapped early.

How to deal with and repair sprocket problems

Sprocket wear treatment

For mild wear of the sprocket, simple running-in and repair can be performed. If the wear is severe, it is recommended to replace the entire sprocket to ensure that the working efficiency of the excavator is not affected.

Repair method:

- Mild wear can be repaired on the surface, and the teeth can be polished with abrasives.

- In case of severe wear, replace the new sprocket and perform equipment correction.

Sprocket deformation repair

When the sprocket is severely deformed, consider replacing the sprocket. For minor deformation, it can be repaired by heating or cold pressing, but if the original accuracy cannot be achieved after repair, it must be replaced.

Repair method:

- Minor deformation can be repaired by precision die casting.

- Severe deformation can be directly replaced by replacing the sprocket and ensuring installation accuracy.

Loose sprocket repair

When the sprocket is loose, first check and tighten all connecting bolts and pins. If any damaged or corroded connecting parts are found, they should be replaced in time to avoid loosening.

Repair method:

- Tighten the loose bolts or pins.

- Replace the damaged connecting parts to ensure a firm connection.

Abnormal noise treatment

When the sprocket makes noise, first check the state of the lubricating oil to ensure that there is no foreign matter stuck in the gear meshing part. If the noise persists, you may need to replace the sprocket or repair the damaged teeth.

Repair method:

- Check and replace the lubricant to ensure lubrication.

- If the noise persists, check whether the sprocket teeth are damaged and replace the sprocket if necessary.

Daily maintenance of sprockets

Regular inspection and cleaning

The surface of the sprocket should be cleaned regularly to remove accumulated dirt and mud to prevent these impurities from affecting the normal operation of the sprocket. Especially in harsh environments, the cleaning of the sprocket should be paid more attention.

Use of lubricating oil

Use high-quality lubricating oil that meets the specifications and replace it regularly. Lubricating oil can reduce friction, reduce wear and increase the service life of the sprocket.

Avoid excessive load

Avoid long-term operation under high load. The reasonable use of the excavator according to the load guidance in the operation manual can effectively reduce the wear of the sprocket.

Operation training

Operator training is essential. Regular training of operators on correct operation and maintenance can effectively reduce equipment failures caused by improper operation.

| Dapatkan penawaran cepat dan gratis | Surel: henry@gfmparts.com | WhatsApp: +86 17705953659 |

As an important transmission component of the excavator, daily maintenance and repair of the sprocket are essential for its service life. By understanding the manifestations, causes and treatment methods of common sprocket problems, combined with daily maintenance and care, you can effectively reduce equipment failures and improve work efficiency. We hope that GFM produsen sproket ekskavator can help you better understand the maintenance knowledge of sprockets and ensure that your excavator is always in the best working condition.