In heavy machinery and equipment, the undercarriage system of the bulldozer is the foundation and core of the operation and function of the whole vehicle. Whether it is filling the factory, water conservancy or heavy transportation procedures, the bottom cover is sailing domineeringly. However, the bulldozer undercarriage parts are the most easily worn and damaged components in the bulldozer, and it is also the part that many operators do not pay enough attention to.

Daftar isi

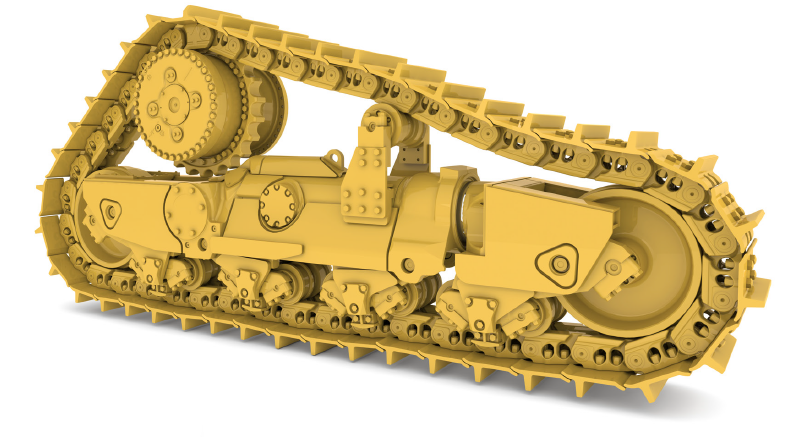

Understand the bulldozer undercarriage system

The composition of the bulldozer undercarriage parts

The bulldozer undercarriage parts are mainly composed of five parts:

- Track idler: complete the pushing function and is the heart of the undercarriage.

- Track chain: connects all parts and converts into a power channel.

- Sprocket roller: Bottoms the belt chain and pushes the upper chain link.

- Guide roller: used to maintain the belt chain shrinkage and perform axial positioning.

- Bottom roller: Bottoms the weight of the whole vehicle and is the most commonly worn component.

These components form a complete undercarriage high-pressure motion system when running, just like the bones and joints of the human body. Any problem in any part may cause the whole vehicle to fail.

Undercarriage wear is common

Because the undercarriage system has been working on clay, cement, sand, gravel, furnaces, and heavy-pressure roads for a long time, it is often polluted by wear, column impact, and rainwater. With the operation of the power shaft, the stress and heat energy increase sharply, causing the roller axle to wear rapidly. If daily maintenance is not performed, a small problem may produce a low cost of thousands of yuan.

GFM Bulldozer Undercarriage Parts Manufacturer

In the construction industry, bulldozers have become vital equipment, and the quality of undercarriage components directly affects the performance and work efficiency of excavators. As a professional bagian bawah buldoser manufacturer, GFM provides a series of high-quality, durable, high-performance chassis parts to help you improve work efficiency and reduce maintenance costs.

Apakah Anda mencari kualitas? bagian buldoser dengan harga terbaik? Anda telah datang ke tempat yang tepat. Kami berkomitmen untuk menyediakan produk yang luar biasa dan menawarkan nilai terbaik bagi pelanggan kami. Kepuasan Anda adalah motivasi kami. Kirim email ke alamat email henry@gfmparts.com sekarang dan para ahli undercarriage buldoser kami akan dengan senang hati melayani Anda.

Daily maintenance and maintenance of bulldozer undercarriage parts

In the field of construction machinery, the undercarriage system of the bulldozer is like a person’s “feet”, Bottoming the weight of the entire equipment and bearing the huge wear and impact caused by rugged terrain and complex environment. If daily maintenance is not in place, problems with the undercarriage parts will not only affect work efficiency, but may also bring serious consequences such as unexpected downtime and increased costs. Scientific and regular maintenance of the bottom cover parts is the key to the long-term stable operation of the equipment.

Check before and after work

The damage of many undercarriage parts does not occur suddenly, but is the result of long-term accumulation. Spending a few minutes to do a simple visual inspection before and after work every day can effectively prevent the expansion of early damage. Misalnya:

- Check whether there are stones, mud or entanglements on the track. If they are not removed in time, these debris will get stuck between the chain link and the sprocket, causing unnecessary friction.

- Observe whether there are abnormal oil stains around the Track idler, Bottoming roller and guide roller. If there are signs of oil leakage, it may indicate that the internal seal ring is aging or the bearing is damaged, which should be dealt with as soon as possible.

- Pay attention to whether the roller is loose, whether there is abnormal tilt or obvious shaking, which may be an early signal of loose fasteners, damaged brackets, etc.

- Gently push the track to feel its tension. Too tight will make the parts work hard, and too loose will easily cause derailment or chain jumping.

These inspection items may seem simple, but they can help you find problems in advance and curb damage that may lead to major repairs in the bud.

Clean regularly

Bulldozers often operate in complex environments such as mud, gravel, and broken bricks, and undercarriage parts are easily surrounded by a lot of mud and gravel. If these impurities are attached between the chain and the roller for a long time, they will continuously polish the metal surface like “sandpaper” and accelerate the wear of parts.

Therefore, it is very necessary to thoroughly rinse the undercarriage part with a high-pressure water gun after each operation. Especially after working in rainy days or in wading areas, it should be cleaned and kept dry in time to prevent rust, jamming or freezing.

In addition, some fine gravel often accumulates between the sprocket and the Bottoming roller, which can easily block the roller rotation. It is recommended to use a screwdriver or a wooden stick to gently remove the remaining debris after each cleaning to keep the parts flexible.

Pelumasan dan perawatan

Many wear and tear of undercarriage parts are not due to poor quality, but lack of lubrication. The Track idler, sprocket and Bottoming roller contain bearings, oil seals, bushings and other components. These parts need grease to reduce direct contact between metal and metal, reduce temperature rise and reduce friction during long-term operation.

Different environments have different requirements for lubrication:

- In a sandy and dusty construction environment, grease is easily mixed with dust and loses its lubricating effect.

- In high-temperature working areas, grease is easy to dilute and lose.

Therefore, new grease should be added regularly according to the environment, neither too much nor too little. Checking once a month is a more reliable frequency, and special environments should be more frequent.

When lubricating, pay attention to using a special grease gun to ensure that the grease enters from the grease nozzle until the old oil is squeezed out. This means that the internal space has been filled and the lubrication is truly effective.

Track tension

Whether the track is in a reasonable tension state directly affects the balance and stability of the whole machine. If the track is too loose, it is easy to slip off the track during turning, climbing and other actions. If it is too tight, each chain link is in a tensioned state, which will easily break the chain pin and increase the wear of the Bottom roller in the long run.

Experienced operators often judge whether the tightness is appropriate by the arc of the track droop. The track droops slightly in the middle, but does not drag on the ground, which is generally normal. If you are not sure, you can also adjust it through the standard measurement method provided by the manufacturer. When adjusting, do not use brute force, but use the tensioning cylinder or screw adjustment mechanism to complete the operation slowly and carefully.

It is worth reminding that every time a new track or chain link is replaced, the tension needs to be readjusted and checked again after a period of operation to ensure stability.

Maintenance focus under different working conditions

Although the undercarriage parts of the bulldozer are similar in structure, the working environment they face may vary greatly, and the maintenance methods should also be different:

In heavy-load conditions such as mines:

The undercarriage will be frequently impacted by boulders, and the rollers and brackets are very easy to deform and wear. At this time, it is recommended to use reinforced materials, such as high-strength steel, integral forging structure, and increase the thickness of the roller body. It is very important to check for cracks and deformation after daily operations, especially to pay attention to whether the centering accuracy of the bracket and the roller axle is offset.

In swamp or wetland environments:

Wet mud can easily wrap the track and roller body, which hinders the rotation of the parts and even causes the whole machine to sink. In such environments, widened track shoes should be used to increase the ground contact area, and mud scrapers should be installed to reduce mud accumulation. After the operation, they should be cleaned immediately and dried thoroughly to prevent metal parts from rusting.

In high-temperature plateau areas:

Metal expands at high temperatures, grease is diluted, and the wear rate of parts may increase significantly. At this time, high-temperature grease needs to be used, and the lubrication condition should be checked frequently. If the rollers are found to be hot or have a slight burning smell, it means that the lubrication is insufficient and the machine should be stopped immediately for inspection.

Judgment criteria for parts replacement

Many users are accustomed to “replacing them when they are broken”, but bulldozers are different from general mechanical equipment. Once their undercarriage system fails, it often causes the entire equipment to stop and even affects the construction progress. Therefore, it is very important to grasp the reasonable time to replace the bottom cover parts.

The following situations indicate that parts may need to be replaced:

- The track shoes have obvious cracks or deformations, and the connection parts are loose, affecting the overall structure.

- The Track idler teeth become sharper, the roller body becomes thinner, and abnormal noise occurs.

- The chain links are loose, the chain pins can no longer be stably connected, and the welding repair effect is not good.

- The sprocket or Bottoming roller does not rotate smoothly, and there is shaking or abnormal noise.

- The track roller is offset and cannot be aligned with the track, resulting in frequent derailment during operation.

Do not underestimate these phenomena. Once the parts fail, it will directly lead to construction interruption, and the maintenance cost and labor cost will be greatly increased.

GFM bulldozer undercarriage parts: born for high-intensity working conditions

Sebagai seorang yang berpengalaman undercarriage parts suppliers, GFM is well aware of the core demands of bulldozer users. The bottom cover parts we provide are not only closer to the actual application scenarios in design, but also strive for excellence in material selection, processing technology, assembly accuracy and other aspects.

- Material: We use wear-resistant alloys such as high manganese steel and high carbon steel, and undergo secondary heat treatment to enhance strength and toughness.

- Process: CNC finishing is used to ensure that each part precisely meets the operation requirements of the whole machine.

- Strong adaptability: Whether you are using a small bulldozer, a wetland machine, or a large-scale equipment dedicated to mining, GFM can provide customized undercarriage parts solutions.

- Fast service response: sufficient inventory, fast delivery, and Bottom for parts matching services worldwide.

| Dapatkan penawaran cepat dan gratis | Surel: henry@gfmparts.com | WhatsApp: +86 17705953659 |

Undercarriage parts are the foundation of the bulldozer. They determine whether the bulldozer can walk stably, work efficiently, and not fall off the chain at critical moments. It is not difficult to do daily maintenance well, and it does not require expensive equipment or tools. It only requires a little bit of meticulous observation and a responsible attitude towards the equipment.

When you really regard the undercarriage as the “first line of defense” of the equipment and adhere to scientific maintenance habits, it will return your trust with fewer failures, longer life, and lower costs. Only by scientifically and systematically maintaining, inspecting, lubricating and adjusting can the equipment be truly “down to earth” and continue to perform its effectiveness in high-intensity, high-frequency, and high-load engineering operations.

Selecting high-quality undercarriage parts, implementing scientific maintenance plans, and matching timely repairs and replacements will bring your bulldozer lower operating costs, longer life cycles, and higher operating efficiency. GFM is also willing to work with global engineering machinery users to jointly create stable, efficient, and lasting operational guarantees.