Produsen Sepatu Track Dozer

- Kualitas Produk Terjamin

- Pasokan Besar

- Harga Kompetitif

- Sebagian Besar Merek & Model

- Tim Layanan Pelanggan yang Membantu

- Dukungan Teknis Profesional

Membagikan

Itu dozer track shoe is a metal plate connected to the track link, neatly arranged on both sides of the track to form a strong ground contact surface. Its main functions are:

- Provide ground grip: Whether it is muddy, mountainous or soft sandy, the chain plate is the key to the bulldozer’s progress.

- Disperse pressure and reduce sinking: The chain plate increases the ground contact area, which can effectively reduce the unit pressure and increase the buoyancy of the bulldozer on soft ground.

- Protect the track links and chassis parts: The chain plate can reduce the impact on other components of the chassis and extend the life of the whole machine.

Therefore, choosing a high-quality track shoe can not only improve the performance of the bulldozer, but also save maintenance costs in long-term operation.

GFM track shoes pursue the ultimate in design and manufacturing. From material selection to processing, every process reflects our persistence in quality.

- High-quality manganese steel or alloy steel material: high-strength wear-resistant steel plate is used, which has excellent impact resistance and wear resistance, and has a longer service life.

- Heat treatment strengthening process: We have improved the overall strength and hardness of the chain plate through the dual processes of whole plate quenching and tempering and high-frequency quenching of the track surface, especially stable performance under high-frequency use environment.

- Standard hole spacing and thickness design: Adapt to most mainstream bulldozer models on the market (such as Komatsu, Caterpillar, Shantui, etc.), and also support non-standard customization.

- Wide track design optional: Provide widened chain plate solutions for special operation scenarios such as swamps and high water areas.

- Anti-rust coating treatment: All chain plates are treated with anti-corrosion coating before leaving the factory, suitable for various extreme weather environments.

Deskripsi Produk

- Jumlah pesanan minimum: 1 buah

- Metode Pembayaran: T/T

- Merek: GFM

- Kondisi: Baru

- Warna: Kuning, Hitam atau Disesuaikan

- Waktu pengerjaan: 30 hari

- Jaminan: 1 Tahun

- Melayani: OEM atau ODM

- Tempat Asal: Fujian, Tiongkok

- Aplikasi: Buldoser

- Sedang mengemas: Palet Kayu Ekspor Standar

Fitur

- Durable & Long-Lasting: Built from high-quality steel to withstand tough jobs.

- Enhanced Stability: Excellent traction for safe operation on any terrain.

- Extended Lifespan: Reduces wear and protects your undercarriage.

- Tahan Karat: Coated for reliable performance in harsh conditions.

- Cost-Effective: Lowers maintenance costs with superior durability.

- Versatile: Perfect for rock, mud, sand, or soft ground.

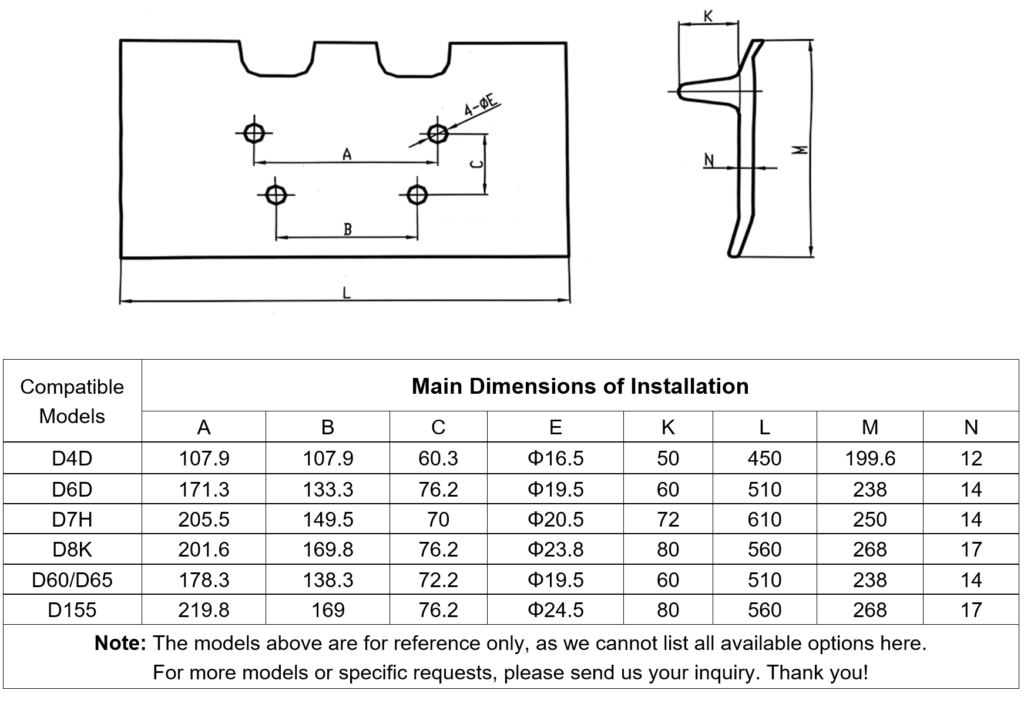

Spesifikasi

Model Produk

Proses Produksi

Pengemasan dan Pengiriman

Keunggulan Pabrik

Sebagai bagian bawah buldoser manufacturer with more than ten years of rich experience, GFM has accumulated rich experience in the field of bulldozer track systems. We have built our own production base, covering an area of more than 10,000 square meters, with advanced facilities such as forging equipment imported from Germany, CNC machining centers, automatic heat treatment lines, and spray anti-corrosion lines.

We have a complete quality control process, from raw material testing, dimensional tolerance control, metallographic analysis, to pre-assembly strength testing, to ensure that each chain plate meets high standards before leaving the factory.

Provide one-to-one customized services to meet your special needs

At GFM, we are well aware that different projects have different needs. Therefore, we provide professional customized services:

- Size customization: According to customer drawings or samples, the required hole spacing, width, thickness and other parameters can be accurately produced.

- Material upgrade: Provide different grades of alloy steel options to meet high-intensity operation scenarios.

- Surface treatment customization: Treatment methods such as galvanizing, electrophoresis, and anti-rust oil can be selected according to needs.

- Small batch proofing and batch delivery: support fast sample proofing, delivery within 3-7 days; batch orders can be flexibly scheduled according to delivery requirements.

Our technical team will assist you from design to finished product, follow up the whole process, and truly “build for customers”.

Whether you are an equipment dealer, terminal construction unit, or equipment maintenance manufacturer, GFM produsen sepatu lari welcomes you to consult with drawings and samples, and we will provide you with professional advice and fast quotation services. Choosing GFM means choosing strength and reliability!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, yang didirikan pada tahun 2011, adalah produsen berpengalaman yang mengkhususkan diri dalam suku cadang ekskavator dan buldoser, seperti suku cadang undercarriage (track roller, carrier roller, idler, sprocket, track shoe, track chain, track group), baut, mur, pin, bushing, dan banyak lagi. Kami menyediakan dan menyimpan berbagai macam suku cadang yang berlaku untuk sebagian besar merek dan model yang tersedia di pasaran. Merek yang kompatibel meliputi Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, dll., yang mencakup merek-merek utama di pasaran.

Tanya Jawab Umum

Kami adalah produsen yang berpengalaman. Pabrik kami berlokasi di Kota Xiamei, Kota Quanzhou. Kunjungan Anda sangat kami nantikan.

Harap berikan model mesin, nomor komponen, atau beberapa spesifikasi yang benar. Jika bukan merupakan barang standar, harap berikan gambarnya.

Kami biasanya menerima T/T; ketentuan lain dapat dinegosiasikan.

Tentu saja bisa. Kami menyediakan layanan OEM. Jika Anda memiliki sampel atau gambar beserta permintaan dalam jumlah besar, kami dapat menyesuaikan barang dan menawarkan dukungan teknis profesional.

GFM telah membangun sistem kontrol kualitas, lingkungan, dan keamanan yang lengkap. Setiap komponen menjalani pengujian ketat dan langkah-langkah kontrol kualitas sebelum didistribusikan. Pabrik kami mematuhi standar keselamatan dan peraturan lingkungan yang ketat dalam proses produksi.

MINTA PENAWARAN SEKARANG

Produk Terkait

- BAGIAN BAWAH

Pabrik Rol Bawah Ekskavator Doosan DH80

- BAGIAN BAWAH

Pemasok Track Roller Ekskavator PC40-5 SF

- BAGIAN BAWAH

Sprocket dan Segmen Excavator dan Bulldozer

- BAGIAN BAWAH

Produsen Roller Pembawa Ekskavator dan Buldoser