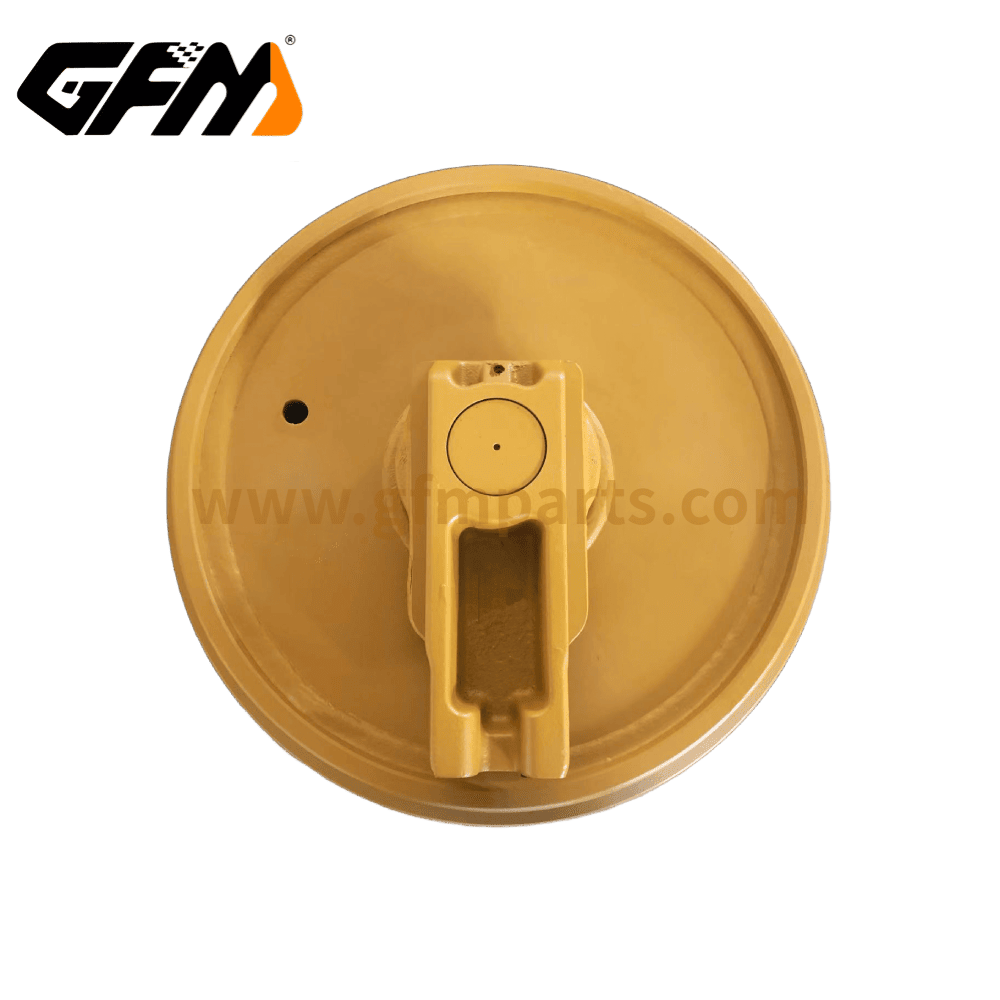

Liebherr R944 Excavator Track Idler Roller

- Kualitas Produk Terjamin

- Pasokan Besar

- Harga Kompetitif

- Sebagian Besar Merek & Model

- Tim Layanan Pelanggan yang Membantu

- Dukungan Teknis Profesional

Membagikan

GFM has specially developed high-quality idlers for the Liebherr R944 excavator to improve work efficiency and service life. As an important component of the track travel system, the penggerak track ekskavator plays the dual role of guiding and tensioning the crawler, and is the key to keeping the equipment running smoothly. ,

Our idlers are tailor-made for the Liebherr R944, perfectly matching its chassis geometry and load requirements.

- Precise matching: diameter, width, bearing hole position, and bracket hole position are all manufactured according to the original R944 factory standards.

- High-strength alloy: heat-treated steel is selected for higher strength and less prone to deformation.

- High-quality bearings: Equipped with imported Swedish roller bearings, with strong load-bearing capacity and reliable dust-proof seals.

- Surface strengthening: The outer ring of the roller is nitrided or carburized, and the wear resistance and corrosion resistance are significantly improved.

- Vibration reduction design: The internal structure is optimized to effectively disperse the impact force and reduce the impact on the chassis and steering mechanism.

- Easy to maintain: Standard lubrication holes are reserved, and daily maintenance only requires simple grease filling to extend service life.

Deskripsi Produk

- Jumlah pesanan minimum: 1 buah

- Metode Pembayaran: T/T

- Merek: GFM

- Kondisi: Baru

- Warna: Kuning, Hitam atau Disesuaikan

- Waktu pengerjaan: 30 hari

- Jaminan: 1 Tahun

- Melayani: OEM atau ODM

- Tempat Asal: Fujian, Tiongkok

- Aplikasi: Penggali

- Sedang mengemas: Palet Kayu Ekspor Standar

Fitur

- Tahan lama:Dibuat untuk bertahan dalam kondisi sulit demi kinerja tahan lama.

- Sangat Cocok: Dirancang agar mudah dipasang pada berbagai model ekskavator dan buldoser.

- Tugas Berat: Mendukung beban berat untuk pengoperasian yang lancar dan stabil.

- Halus & Tenang: Meminimalkan getaran untuk pergerakan yang lebih halus dan meningkatkan traksi di semua medan.

- Perawatan Rendah: Pelumasan sendiri untuk lebih sedikit perawatan dan lebih banyak waktu aktif.

- Tahan Cuaca: Berfungsi baik di segala iklim, tahan karat dan suhu ekstrem.

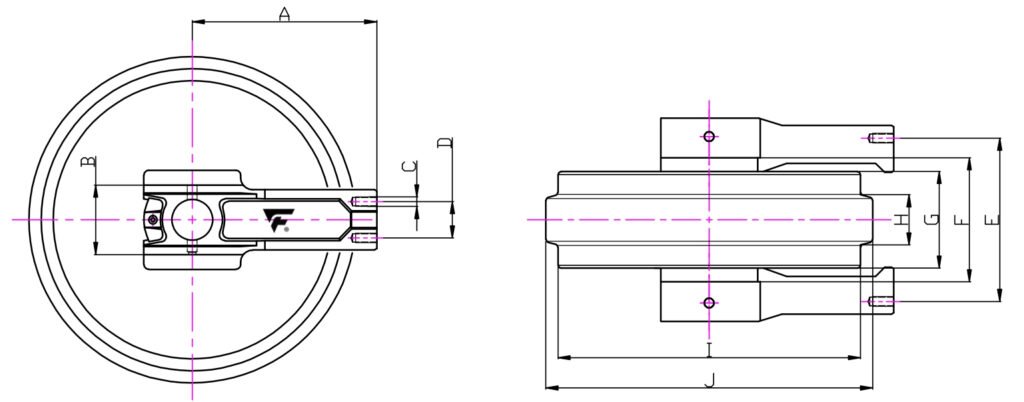

Spesifikasi

Model Produk

Proses Produksi

Dari desain hingga pengiriman, setiap mata rantai proses produk kami dikontrol secara ketat untuk memastikan stabilitas dan ketahanan produk. Berikut ini adalah pengantar alur proses dasar:

- Raw material inspection

- Select high-quality alloys and high-strength materials, and undergo strict chemical composition analysis and mechanical property testing.

- Clear test data records ensure that the materials fully meet the standard requirements.

- CNC machining and molding

- Use high-precision CNC machine tools for precision machining to ensure the dimensional accuracy of parts.

- The molding process has been repeatedly optimized to make the product surface smooth and avoid wear problems caused by machining defects.

- Surface treatment and heat treatment

- According to different application environments, select suitable surface treatment methods, such as spraying, galvanizing, etc., to improve the corrosion resistance of the product.

- The heat treatment process improves the internal structure of the material, increasing its hardness and wear resistance.

- Strict inspection and testing

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

At the same time, through simulated on-site working condition testing, the idler wheel is ensured to perform well in actual use.

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

Pengemasan dan Pengiriman

Keunggulan Pabrik

GFM PARTS professional produsen idler ekskavator has many years of manufacturing experience and strong technical force, and all equipment has reached the international advanced level. The following is a brief introduction to our factory advantages:

- Advanced production equipment: The introduction of multiple internationally leading CNC machining centers and fully automatic testing equipment ensures that each product is precisely processed and tested.

- Quality management system: Strictly operate in accordance with the ISO quality system, and there are detailed records from raw material acceptance to finished product delivery to ensure that every link is traceable and product quality is based on evidence.

- Professional R&D team: After years of market precipitation and technical accumulation, we have an experienced and skilled R&D team. We can respond quickly to customer needs and continuously optimize product design and process flow.

- Strong customization capability: The factory can flexibly adjust the production line to undertake small and medium-sized batches and large-scale orders. Whether it is special materials, complex processes or unique designs, they can be customized according to needs.

Advantages of customized services

GFM understands the special needs under different working conditions and provides flexible and comprehensive customized solutions to help you achieve the best performance:

- Material selection: Conventional alloy steel, high-toughness alloy or high-temperature resistant steel can be provided according to the working conditions to meet extreme environments.

- Special coating: Optional spray anti-corrosion, anti-stick or high-temperature resistant coating, suitable for complex working conditions such as seaside, desert, high heat, etc.

- Structural optimization: Supports design improvements such as increasing tensioning stroke, widening bearing surface, and improving sealing structure to improve track tensioning and guiding performance.

- Packaging and logistics: Provide moisture-proof film, anti-seismic filling and customized wooden box packaging to ensure that parts are intact during long-distance transportation.

- Exclusive drawings and numbers: Mark according to customer work number or project number to facilitate subsequent spare parts management and batch order tracking.

Friendly suggestions and practical tips

Sebagai sebuah pabrik suku cadang ekskavator, we not only provide high-quality products, but also hope to share some tips on using and maintaining track idler roller with customers to help you manage equipment more easily.

- Regular inspection: It is recommended to check the idler for obvious signs of wear or damage before and after each operation to detect problems in time and extend the life of the product.

- Proper installation: During the installation process, strictly follow the installation manual to ensure that all joints are firm to avoid affecting the operation of the equipment.

- Maintenance notes: Clean and lubricate the idler regularly to reduce the impact of dust and impurities on the friction surface and keep it running smoothly.

- Professional training: We regularly hold technical exchanges and training activities, invite customers to participate, and jointly discuss equipment maintenance methods and process improvement suggestions.

These practical tips can not only help you reduce the risk of failure in actual operations, but also provide strong guarantees for the long-term maintenance of equipment.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, yang didirikan pada tahun 2011, adalah produsen berpengalaman yang mengkhususkan diri dalam suku cadang ekskavator dan buldoser, seperti suku cadang undercarriage (track roller, carrier roller, idler, sprocket, track shoe, track chain, track group), baut, mur, pin, bushing, dan banyak lagi. Kami menyediakan dan menyimpan berbagai macam suku cadang yang berlaku untuk sebagian besar merek dan model yang tersedia di pasaran. Merek yang kompatibel meliputi Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, dll., yang mencakup merek-merek utama di pasaran.

Tanya Jawab Umum

Kami adalah produsen yang berpengalaman. Pabrik kami berlokasi di Kota Xiamei, Kota Quanzhou. Kunjungan Anda sangat kami nantikan.

Harap berikan model mesin, nomor komponen, atau beberapa spesifikasi yang benar. Jika bukan merupakan barang standar, harap berikan gambarnya.

Kami biasanya menerima T/T; ketentuan lain dapat dinegosiasikan.

Tentu saja bisa. Kami menyediakan layanan OEM. Jika Anda memiliki sampel atau gambar beserta permintaan dalam jumlah besar, kami dapat menyesuaikan barang dan menawarkan dukungan teknis profesional.

GFM telah membangun sistem kontrol kualitas, lingkungan, dan keamanan yang lengkap. Setiap komponen menjalani pengujian ketat dan langkah-langkah kontrol kualitas sebelum didistribusikan. Pabrik kami mematuhi standar keselamatan dan peraturan lingkungan yang ketat dalam proses produksi.

MINTA PENAWARAN SEKARANG

Produk Terkait

- Rol lintasan

Produsen Track Roller Ekskavator Rol Bawah CAT E70B

- BAGIAN BAWAH

Pabrik Roller Bawah Buldoser Terbaik

- BAGIAN BAWAH

Pemasok Sprocket Excavator Berkualitas Tinggi

- Rol lintasan

Produsen Rol Bawah Berkualitas Tinggi