Table of contents

- What are the track rollers of Komatsu excavators?

- Which is better, Hitachi excavator or Komatsu excavator?

- How to choose high-quality excavator rollers?

- Adaptation to different brands

- Quality inspection standards

- Installation and maintenance of excavator track rollers

- Replacement and upgrade of rollers

- Production process and quality control of GFM track roller factory

In the field of construction machinery, excavators are an important type of construction machinery, and excavator undercarriage parts, as their core components, directly affect the working performance and life of the whole machine. Among them, the track roller is an important part of the excavator undercarriage. Its main function is to support the crawler and ensure the stable driving of the machine on complex terrain. Choosing the right track roller can not only improve the working efficiency of the equipment, but also effectively reduce the maintenance cost.

What are the track rollers of Komatsu excavators?

As an important part of the undercarriage system, the track rollers of Komatsu excavators are mainly used to carry and support the weight of the machine. The design of the track rollers requires high strength and wear resistance, and can adapt to various harsh working environments. The track rollers of Komatsu excavators are usually made of high-strength steel, and are precision cast and strictly heat treated to ensure that the product maintains stable performance during long-term use. In order to ensure its quality, many excavator undercarriage manufacturer have adopted advanced testing equipment and passed the ISO certification system to ensure the reliability of the products.

Role and Function

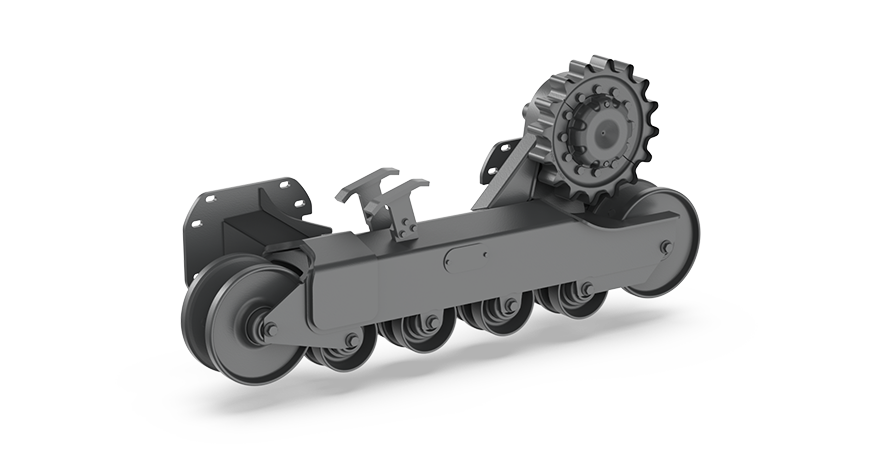

The track roller is located at the bottom of the excavator crawler, carrying the weight of the equipment and guiding the crawler to run correctly. It plays a role in bearing, buffering and stabilizing the entire walking system, and can reduce the loss caused by ground vibration.

Structural composition

The track roller is mainly composed of wheel body, bearing, oil seal, sealing ring and other parts. Its shell is usually made of high-strength alloy steel to withstand huge impact and wear, while the internal lubrication system ensures its long-term stability.

Common types

- Single-sided track roller: suitable for small excavators, light weight and easy installation.

- Double-sided track roller: suitable for large excavators, strong bearing capacity and higher wear resistance.

- Reinforced track roller: designed for harsh environments, stronger impact resistance, suitable for harsh working conditions such as mines and wetlands.

Which is better, Hitachi excavator or Komatsu excavator?

In the excavator market, Hitachi excavator and Komatsu excavator are two important brands. Both have their own advantages in design concept, manufacturing process and product stability. Komatsu excavator has won a good reputation in the industry for its exquisite craftsmanship and high-standard quality, while Hitachi excavator relies on advanced technology and continuous innovation to maintain its competitiveness. Specifically, Komatsu excavator rollers are outstanding in durability and wear resistance, while Hitachi excavators have more advantages in intelligent control systems and fuel economy.

In the actual selection process, users should make a comprehensive assessment based on the operating environment and needs. If you focus on long-term stability and maintenance costs, Komatsu excavator rollers are a reliable choice; for users who pursue the latest technology and energy-saving effects, you can consider Hitachi excavators. Regardless of which brand you choose, it is recommended to conduct regular inspections and perform maintenance as required to ensure efficient operation of the equipment.

How to choose high-quality excavator rollers?

Material and manufacturing process

High-quality rollers are usually made of forged steel or alloy steel, and are quenched and heat treated to improve wear resistance and impact resistance. In addition, the internal bearings use a double-layer sealing structure, which can effectively prevent mud and water from entering and increase service life.

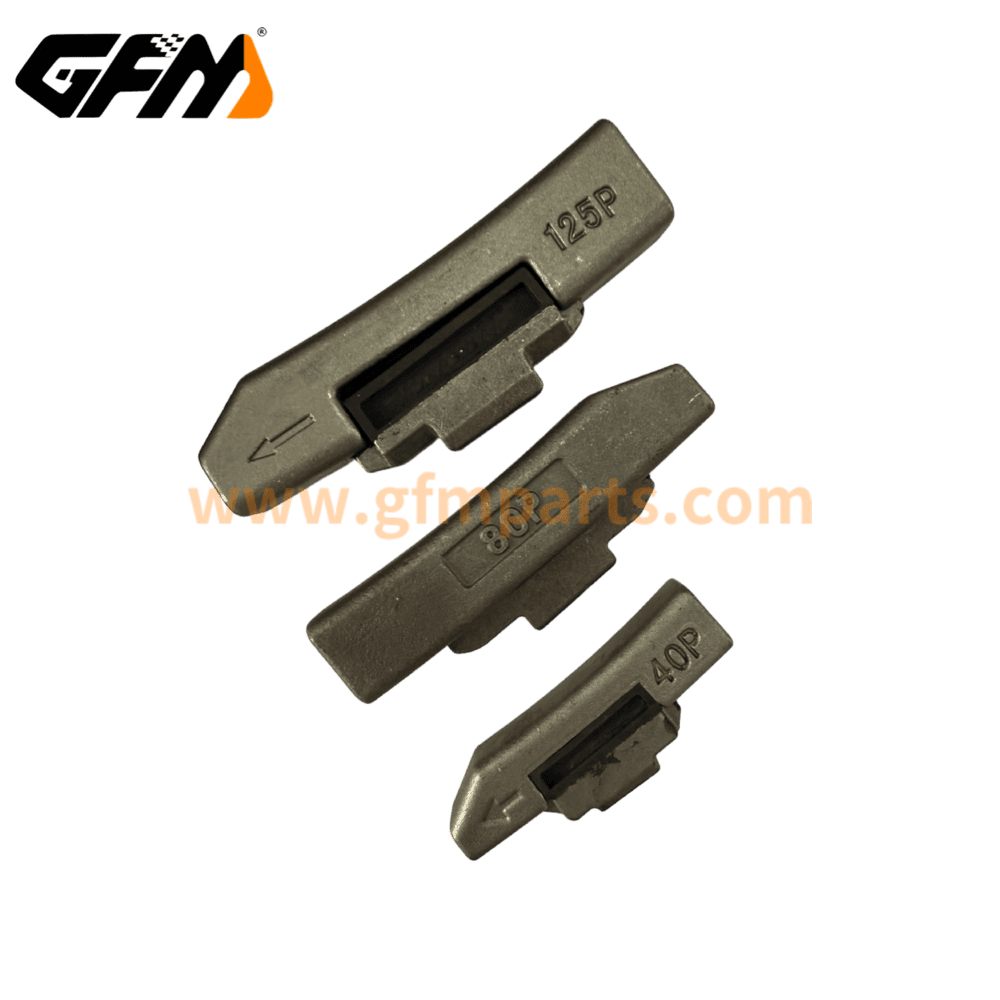

Adaptation to different brands

There are differences in undercarriage design between excavators of different brands, so it is necessary to ensure their adaptability when selecting rollers. For example:

- Komatsu track rollers are known for their durability and are suitable for high-intensity operations.

- Hitachi track rollers emphasize stability and are suitable for fine operations.

- Caterpillar track rollers are both durable and stable and are widely used in various engineering projects.

Quality inspection standards

When purchasing track rollers, pay attention to the following inspection standards:

- Hardness test (HRC 52-58): Ensure that the wheel body is wear-resistant and not easy to deform.

- Seal test: Ensure that the lubricating oil does not leak and prevent damage to internal components.

- Load test: Simulate the working environment to ensure that the track roller can withstand high-intensity use.

Installation and maintenance of excavator track rollers

Correct installation steps

- Clean the installation location to ensure that there are no foreign objects or oil stains.

- Align the mounting holes and use special tools to fix the bolts.

- Tighten the bolts appropriately to avoid over-tightening or over-loosening to affect performance.

- Test the rotation to ensure that the wheel body runs smoothly.

Daily inspection and maintenance points

- Check the amount of lubricating oil regularly to ensure good lubrication.

- Observe whether the seal is intact to prevent mud and sand from entering and damaging the internal structure.

- Check the wear and tear. If there is deep wear or cracks on the wheel surface, it should be replaced in time.

Possible faults and solutions

| Fault | Possible cause | Solution |

| Abnormal noise | Bearing wear or insufficient lubrication | Replace bearing or add lubricating oil |

| Oil leakage | Seal ring aging or damage | Replace seal ring |

| Wheel body crack | Excessive impact or material fatigue | Replace new wheel in time |

Precautions

Proper installation and maintenance of the track wheels are essential to extend the service life of the excavator. The following are the installation and maintenance tips I have summarized in my actual work:

- Pre-installation inspection: Before installing the track wheels, carefully check whether the parts are defective. Use a torque wrench to tighten the bolts according to the manufacturer’s requirements to ensure a firm installation.

- Regular cleaning: At the construction site, dust and debris are easy to accumulate on the surface of the track wheels. It is recommended to clean weekly and use professional cleaning agents to remove dust to avoid corrosion caused by pollution.

- Temperature monitoring: The rollers will generate high temperatures during long-term operation. It is recommended to equip them with temperature sensors to monitor the working temperature in real time to prevent the degradation of material properties due to overheating.

- Wear detection: Check the wear of the rollers regularly. If cracks or deformations are found, they must be replaced in time. Using professional testing instruments can more accurately assess the degree of wear.

- Record maintenance logs: It is recommended to establish detailed maintenance records, including each maintenance, replacement of parts and test data, so as to facilitate future tracking of equipment conditions.

These methods can not only increase the service life of the rollers, but also reduce downtime caused by sudden failures. Adopting these practical suggestions can make the equipment run more stable and efficient, and further reduce maintenance costs.

Replacement and upgrade of rollers

When do you need to replace them?

Generally speaking, the life of excavator rollers is 2000-5000 hours, but the specific replacement time depends on the working environment and the intensity of use. If the following problems are found, you should consider replacing them:

- The wheel body is severely worn, affecting the operation of the track.

- The internal lubrication system is damaged, causing the wheel body to jam or heat up.

- Bearings make unusual noises or are noticeably loose, affecting equipment stability.

Choose original parts vs. cost-effective alternatives

- Original parts: stable quality, but higher prices, suitable for long-term high-intensity operations.

- Cost-effective alternatives: lower costs, but you need to choose a reputable manufacturer, such as GFM rollers, to ensure quality and durability.

Maintenance cost comparison

A set of high-quality rollers costs between $100-500, but choosing high-quality products can reduce the frequency of replacement, which can effectively reduce total maintenance costs in the long run.

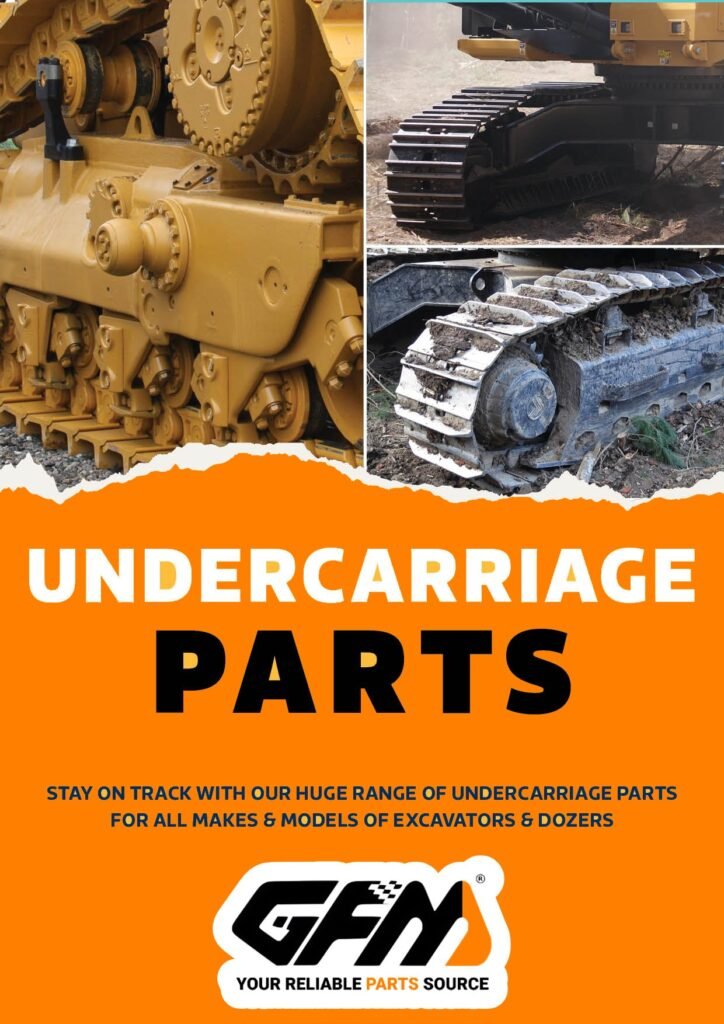

Production process and quality control of GFM track roller factory

The track roller factory uses precision machining and automated testing technology in the production process to ensure that each product meets strict quality standards. The production process is mainly divided into raw material selection, casting, heat treatment, processing, testing and assembly. Each link is monitored by a dedicated person to ensure that the product is in the best condition throughout the production process.

In the casting stage, the factory uses high-precision molds to cast to ensure the precise shape of the rollers; then in the heat treatment stage, a strict temperature control procedure is used to improve the hardness and wear resistance of the material. During the processing, CNC machines are used for fine cutting and grinding to ensure that all parameters are accurate. Finally, a full range of inspections are carried out before leaving the factory, including multiple indicators such as size, hardness and wear resistance, to ensure that the product can work stably for a long time in harsh environments.

In addition, many roller factories have also introduced Internet of Things technology to achieve real-time data monitoring and quality traceability. With these advanced means, factories can quickly locate production problems and optimize process flows, thereby greatly reducing product defect rates.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Choosing a reliable excavator undercarriage manufacturer is the key to ensuring the quality of the entire machine. Excellent manufacturers usually have the following characteristics: advanced production equipment, strict quality inspection system, professional technical team and rich market experience.

When choosing a manufacturer, its production process and after-sales service should be focused. Some well-known companies conduct regular technical training to ensure that technicians have the latest testing and maintenance knowledge. Through close cooperation with manufacturers, users can obtain timely and effective technical support and product upgrade suggestions

As a professional excavator undercarriage parts manufacturer, GFM provides high-quality track rollers with excellent durability and stability, providing customers with reliable solutions.

Through correct selection and maintenance, you can significantly improve the performance of the excavator, reduce operating costs, and make the equipment perform at its best under various working conditions.

Disclaimer: All third-party brand names, logos, and trademarks—such as Caterpillar, Komatsu, and others—belong to their respective owners. They are used on this website for reference and demonstration purposes only. GFM Parts is not affiliated with, endorsed by, or sponsored by any of these brands.