Bulldozer track shoes are an indispensable key component in the operation of bulldozers. They directly affect the traction, stability and ability to adapt to different terrains of the equipment. According to the application environment, track shoes are divided into two categories: track shoes and swamp track shoes.

Function and basic structure

Bulldozer track shoes are a steel component that connects the track chain links and are closely related to the operating efficiency and ground adaptability of the bulldozer. Its main functions include:

- Improve traction: By increasing the contact area with the ground, the bulldozer can obtain stronger grip on different terrains.

- Protect the chassis system: Effectively disperse the weight of the bulldozer and reduce wear on the chassis.

- Adapt to special terrain: According to the design differences of the track shoes, it can cope with complex terrains such as mud, swamps, and sand.

Generally speaking, track shoes are made of high-strength steel, with high surface hardness and wear resistance, and can maintain stable performance in harsh environments.

Characteristics and Applications of Track Shoes

Characteristics

- Stable design: Conventional track shoes are usually thicker, and the tooth design is suitable for hard ground, such as sandy and gravel ground, hard soil layer, etc.

- Strong durability: Its material and processing technology determine good wear resistance, suitable for long-term high-intensity work.

- Excellent grip: Provides sufficient traction on hard ground or gentle slope environment.

Applicable scenarios

- Hard ground such as construction sites and mining operations.

- Tasks that require long-distance earthmoving.

- Environments with low requirements for ground protection.

Purchase suggestions

When purchasing conventional track shoes, pay attention to the following points:

- Plate thickness and tooth design: Ensure that the terrain requirements are met.

- Material and process: High-strength track shoes treated with heat treatment are preferred, which are wear-resistant and extend the service life.

Characteristics and Applications of Swamp Track Shoes

Characteristics

- Wide plate design: Swamp track shoes are wider than conventional track shoes to increase the ground contact area and prevent sinking.

- Combination of light weight and high strength: The special design can maintain light weight and ensure durability.

- Self-cleaning performance: The tooth design takes into account the drainage needs of mud and wetlands, and it is not easy to accumulate mud.

Applicable scenarios

- Soft ground such as wetlands and swamps.

- Environments that require buoyancy such as paddy field projects and river management.

- Projects with high environmental protection requirements need to reduce damage to the surface.

Purchase suggestions

When choosing swamp track shoes, pay attention to:

- Width matching: Select the appropriate width according to the bulldozer model and operating environment.

- Mud discharge capacity: Prefer products with reasonable tooth design to reduce maintenance frequency.

- Corrosion resistance: Adapt to long-term operation requirements in humid environments.

Advantages of GFM bulldozer track shoes

As an industry-leading bulldozer track shoe manufacturer, GFM is committed to providing high-quality track shoe products. Whether it is conventional track shoes or swamp track shoes, we have excellent performance in the following aspects:

- Material selection: Use high-strength steel, combined with advanced heat treatment technology to improve durability and strength.

- Customized service: Support OEM/ODM customization for customer-specific needs and provide exclusive design solutions.

- Quality certification: Strictly produce in accordance with international standards to ensure stable and reliable products.

- Adequate inventory and fast delivery: Our modern factories and perfect supply chain ensure on-time delivery.

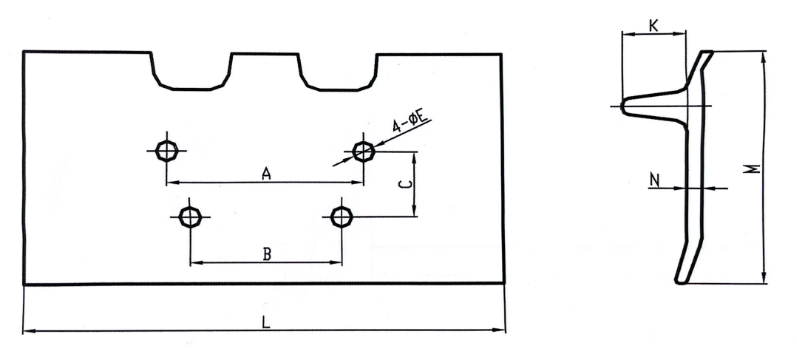

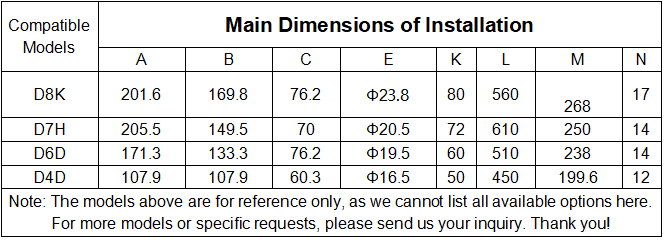

How to choose the right track shoe?

When choosing bulldozer track shoe, you need to consider the specific application scenario:

- Terrain type (hard ground, soft ground or mixed terrain).

- Operation task (traction requirements, load weight, etc.).

- Bulldozer model (matching size and specifications).

If you have any questions about product selection or need a quote, please feel free to contact the GFM team, our professional consultants will provide you with one-on-one service!

Email: henry@gfmparts.com

Whatsapp: +86 17705953659