Bulldozer Track Chain Manufacturer

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM bulldozer train chain is made of high-strength alloy steel, and has undergone precise heat treatment and surface hardening treatment to ensure the extraordinary wear resistance and tensile strength of the chain under extreme working conditions. The unique design optimizes the engagement between the chain and the sprocket, reduces friction loss, and prolongs the service life. Whether in harsh mining or heavy construction sites, our bulldozer chains can ensure the continuous and efficient operation of your equipment with excellent performance.

Product Description

- Technique: Forging

- Raw Material: 35MnBH

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Sealed and Oil-Lubricated

- Increased Mobility and Speed of Tracking

- 50% Longer Working Life

- Reduced Contamination and Maintenance

- Higher Sustainability and Durability

At GFM Factory, we use oil instead of grease for bulldozer track links due to its superior lubrication and performance. Unlike grease-lubricated track links, oil-lubricated systems have more space between the pin and the bushing. After the pin is pressed into place, the space is vacuum-sealed and filled with oil, ensuring the gap is fully occupied for optimal lubrication. This process also checks that the track’s seal is intact, which is critical for preventing wear and ensuring the track performs at its best.

Oil is the ideal choice for track links, providing enhanced wear protection, effective heat dissipation, and helping to keep contaminants out. It also reduces the need for frequent maintenance. These benefits make oil-filled bulldozer track links a durable, efficient, and reliable solution for heavy-duty machinery, ensuring long-lasting performance.

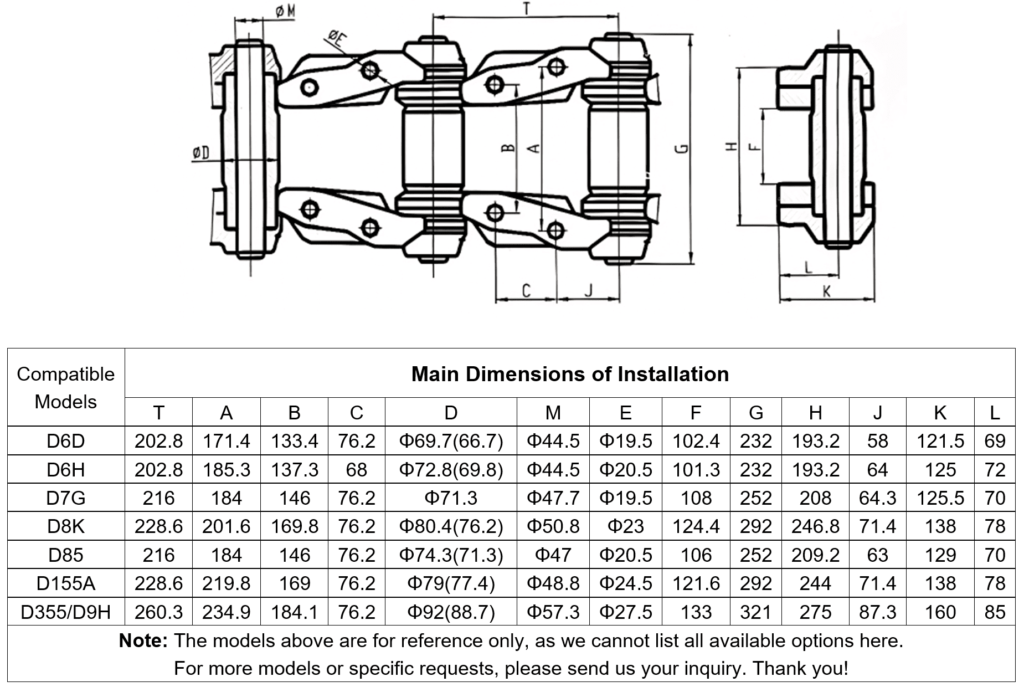

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

As an industry-leading bulldozer track link assy factory, GFM has advanced production lines and a strict quality control system. From raw material procurement to finished product delivery, every step is carefully screened and strictly tested to ensure that each chain meets the highest standards. Our R&D team continues to innovate, keep up with market trends, and provide customized solutions for customers. In addition, the factory is large in scale and has sufficient inventory, which enables it to respond quickly to customer needs, achieve efficient production and on-time delivery.

When looking for high-performance bulldozer chains, our factory is your best choice. We focus on producing high-quality bulldozer chains, using top materials and processes to ensure that the chains have ultra-long service life and excellent performance. As a bulldozer chain factory with rich manufacturing experience and advanced technology, we not only provide standardized products, but also customize designs according to customer specific needs to meet diverse application scenarios. From the careful selection of raw materials to the strict testing of finished products, we always adhere to the principle of quality first to ensure that each product can withstand the test of the market. Choosing our bulldozer chain means choosing professionalism, trust and success.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

PC40-5 SF Excavator Track Roller Supplier

- Track Group

Bulldozer Track Group Manufacturer

- UNDERCARRIAGE

High Quality Bottom Roller Manufacturer