CAT 305 Excavator Track Idler

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM PARTS excavator idler suppliers has been committed to the research and development and production of excavator accessories for many years, especially track idlers for CAT 305 excavators. With rich manufacturing experience and high-precision technology, it provides customers with high-quality products.

Our excavator track idlers are made of high-quality alloy materials and processed through multiple processes. Each link is strictly tested to ensure wear resistance and corrosion resistance. The product has a reasonable design and compact structure, which is suitable for various working requirements of CAT 305 excavators. Specific advantages include:

- Excellent wear resistance: effectively extend the service life of the product and reduce the replacement cost caused by loss.

- Precision processing technology: every detail is carefully polished to ensure the stability and safety of the product.

- Strong adaptability: precise matching CAT 305 excavator, simple installation and convenient use.

- High-strength design: can withstand long-term high-load work to ensure stable operation of the equipment.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

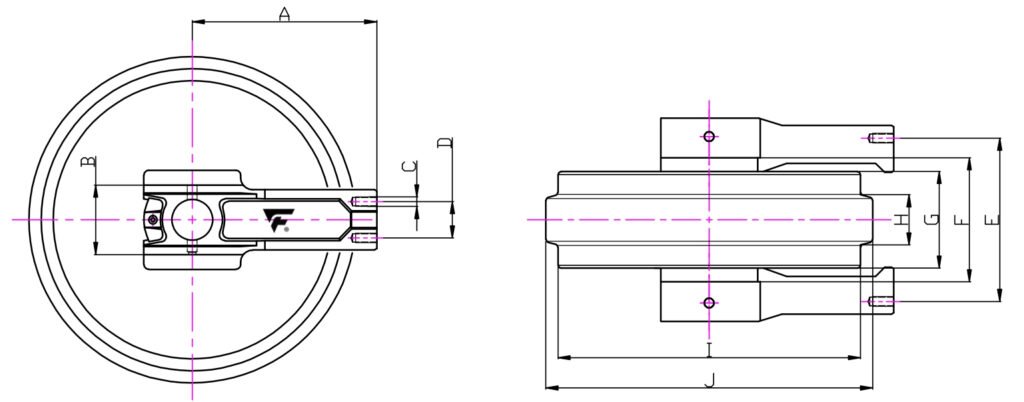

Specifications

Product Models

Production Process

To ensure that each track idler can achieve optimal performance, our production process uses fully automatic CNC equipment and a strict quality inspection system:

- Raw material selection: Use certified high-quality alloys to ensure that the base material is strong and durable;

- Precision casting and machining: Combined with high-tech CNC systems, ensure that the product size is accurate and the error is controlled within a very small range;

- Surface treatment: Use advanced spraying and anti-corrosion technology to enhance the product’s wear resistance and corrosion resistance;

- Strict testing: Each product will undergo multiple performance tests before leaving the factory to ensure that it meets the design standards;

- Packaging and transportation: Carefully designed packaging to ensure the safety of the product during transportation, so that customers can use it with peace of mind.

Packaging and Shipping

Factory Advantages

We are a factory specializing in the manufacture of excavator accessories, with modern workshops and advanced testing equipment. The factory has an experienced technical team and engineers. It not only masters the internationally leading manufacturing process, but also continuously introduces automated production equipment to ensure the high quality and high efficiency of the products.

- Years of quality accumulation: Through continuous market testing, it has won the trust and praise of customers.

- Keep improving: Strictly control every production link to ensure that from raw material procurement to product delivery, it meets international standards.

- Continuous innovation: Actively develop new materials and new processes to adapt to the ever-changing needs of the market.

Customized service

During the production process, we fully understand the special needs of each customer for the product, so we provide a full range of customized services. Whether it is size, material, surface treatment or special purpose requirements, we can customize processing according to the technical requirements provided by the customer. Our team of engineers will communicate with you one-on-one, from product design to production delivery, to provide you with professional advice and technical support throughout the process.

- Personalized customization: Provide the best solutions for different use environments and special working conditions.

- Quick response: After the customer makes a request, we will give professional feedback and implementation plans in the shortest time.

- Technical support: Provide practical application suggestions to help customers achieve equipment maintenance and cost optimization.

- Continuous service: Provide continuous technical support and after-sales service after leaving the factory to ensure that customers have no worries.

Practical suggestions and technical tips

In order to keep the CAT 305 excavator in the best condition after long-term operation, we recommend that users regularly check the wear of the track idler and follow the following suggestions:

- Check the track connection part every once in a while to ensure that there is no looseness or cracks.

- Regularly clean the mud and impurities in the working environment to prevent foreign objects from wearing the product surface.

- If abnormal wear of the product is found, contact the manufacturer’s technical support in time to avoid equipment downtime due to failure.

- During installation and disassembly, strictly follow the operating manual to ensure that there are no omissions in each link.

- It is recommended to have a certain number of track idlers in stock in case of urgent replacement to ensure work continuity.

Installing track idlers

In order to help customers install and maintain track idlers more conveniently, we have compiled some practical steps and tool suggestions:

- Tool list: pliers, wrenches, fastening bolts and special testing instruments.

- Operation steps:

- Prepare tools: Make sure all necessary tools are complete and wear personal protective equipment.

- Remove old parts: Carefully remove the old track idler, and pay attention to record the installation direction and position.

- Cleaning and inspection: Clean the installation area and check for damage.

- Install new parts: Install the new track idler in sequence and tighten the bolts to ensure that each connection point is firm.

- Trial run: After the installation is completed, start the equipment for trial run, observe whether there are any abnormal phenomena and make timely adjustments.

Precautions: Keep the working environment clean, avoid damage to the product by tools, and pay attention to personal safety during installation.

Friendly service and quality commitment

Our goal is to let every customer enjoy high-quality products and considerate services. The factory not only pays attention to product quality, but also pays more attention to interaction and communication with customers. We promise:

- Each track idler has a detailed product manual and user guide.

- If customers encounter problems during use, they can contact us for technical support at any time.

- Regularly provide the latest product and technical training information to help you master practical maintenance skills.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Track Idler

Kubota Mini Excavator U15 Idler

- UNDERCARRIAGE

Komatsu PC1100 PC1250 Idler for Excavator 21N-30-33110

- Track Idler

Track Idler Parts Komatsu D30 Bulldozer Idler

- Track Idler

High Quality Excavator Track Idler Manufacturers