CAT K130 Excavator Bucket Tooth Pin Manufacturer 220 9130

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM specializes in producing high-quality CAT K130 Excavator Bucket Tooth Pin 220 9130, providing reliable wear-resistant solutions for heavy-duty construction machinery. As a professional excavator tooth pin manufacturer, we understand that every bucket tooth pin plays a critical role in excavation efficiency and machine longevity.

High-Strength Material: GFM uses premium alloy steel, processed with special heat treatment, ensuring that each bucket tooth pin maintains excellent resistance to bending and breaking under heavy loads.

Precision Fit: Each bucket tooth pin is manufactured strictly according to CAT K130 specifications, ensuring perfect compatibility with the original bucket, easy installation, and reduced risk of loosening or excessive wear.

Superior Wear Resistance: Optimized surface hardness combined with internal toughness ensures long-lasting performance in various challenging conditions, such as soil, gravel, and construction debris.

Wide Application: Designed specifically for CAT K130 excavators and compatible bucket models, providing stable and reliable performance.

GFM’s bucket tooth pins have earned widespread recognition in the market for their reliability and cost-effectiveness, delivering efficient operational experiences for customers.

Product Description

- Raw Material: 40CR

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Built for durability and precision, GFM bucket teeth pins ensure maximum efficiency for your heavy-duty tasks.

Features

- Durable Material: Premium alloy steel for extreme wear resistance.

- Perfect Fit: Precision-engineered to reduce wear and improve stability.

- Heat Treated: Enhanced hardness for longer service life.

- Rust-Resistant: Anti-corrosion coating for lasting performance.

- Easy Installation: Quick and hassle-free replacement.

Choose GFM for reliable, cost-effective bucket teeth pins compatible with a wide range of excavators.

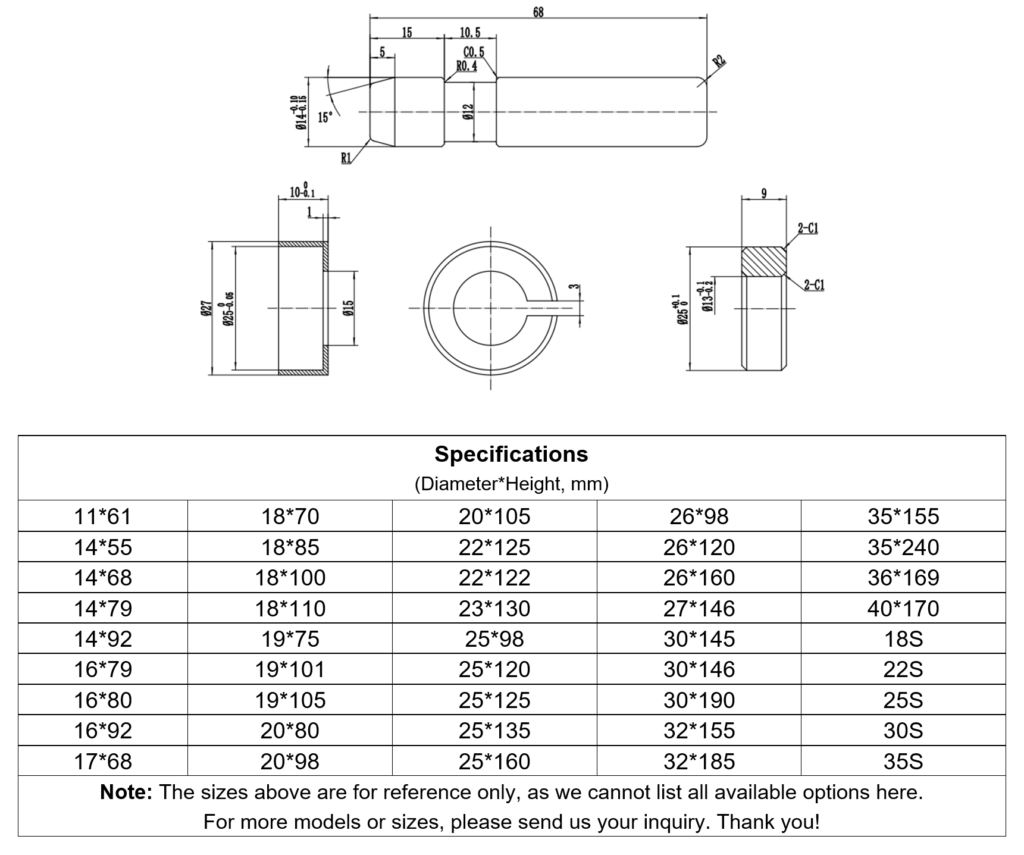

Specifications

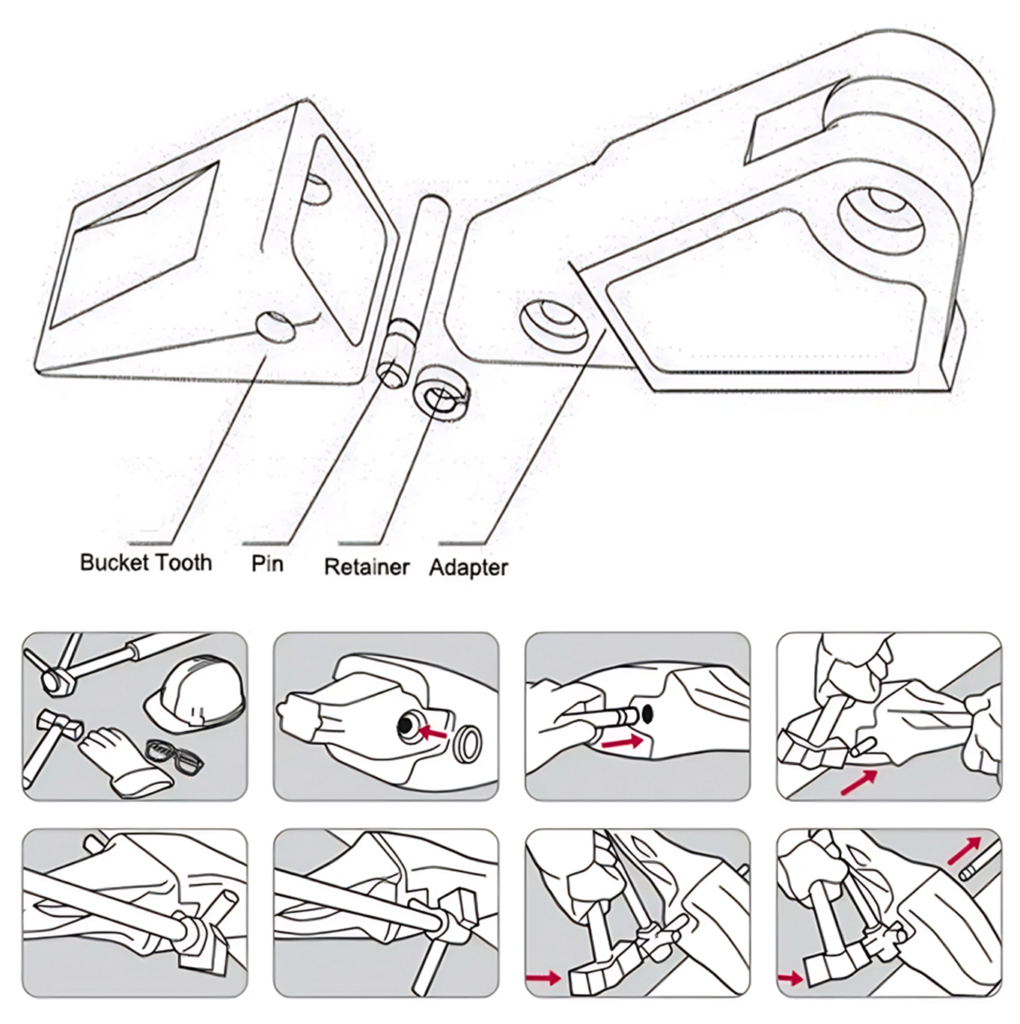

Installation Steps

Product Models

Production Process

As a professional excavator parts manufacturer, GFM PARTS has first-class production facilities and an experienced team of engineers. With many years of manufacturing experience, it has become a recognized authoritative manufacturer in the industry. The factory introduces advanced processing equipment and strictly controls every link from raw material selection to finished product delivery. Specifically, our production process includes:

Material testing and selection: ensure that each batch of steel meets international standards

Precision machining: use CNC equipment to achieve high-precision machining

Surface treatment: use multiple processes for anti-corrosion and anti-wear processes

Final inspection: multiple quality inspection procedures to ensure product quality

Each process is operated by professional technicians to ensure high consistency and high reliability in the production process. We are well aware of the importance of product quality to engineering safety, so we strictly implement the ISO quality system and strive to provide customers with products and services that exceed expectations.

Packaging and Shipping

Factory Advantages

Choosing GFM means choosing an experienced, technologically advanced, and customer-focused partner. The factory advantages include:

Rich Experience: Over 20 years of experience in excavator tooth pin production, familiar with various excavator models and pin requirements. GFM has supplied stable, reliable products to large-scale projects both domestically and internationally.

Advanced Equipment: Equipped with high-precision forging machines, CNC centers, and heat treatment facilities, enabling fully controlled production from raw materials to finished products, improving efficiency and precision.

Strict Quality Control: Complete quality management system ensures each batch meets international standards through material checks, process monitoring, and final inspection.

Reliable Delivery: Stable production capacity and a well-organized logistics system guarantee on-time delivery, avoiding project delays.

Friendly Service: The GFM team communicates in a professional yet approachable way, offering technical consultation and after-sales support to help customers select the most suitable bucket tooth pin solutions.

In summary, GFM’s CAT K130 Excavator Bucket Tooth Pin excels in quality, wear resistance, and precision. Combined with the factory’s technical strength and service advantages, it ensures every customer enjoys efficient and reliable operation. Whether for large-scale construction or small excavation projects, GFM is a trusted excavator tooth pin supplier.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Bucket Tooth Pins

Doosan DH150 Bucket Tooth Pin and Retainer

- Bolt and Nut

Excavator and Bulldozer Track Roller Bolts

- Bolt and Nut

Track Shoe Bolts and Nuts Manufacturer