Dozer Track Shoes Manufacturers

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

The dozer track shoe is a metal plate connected to the track link, neatly arranged on both sides of the track to form a strong ground contact surface. Its main functions are:

- Provide ground grip: Whether it is muddy, mountainous or soft sandy, the chain plate is the key to the bulldozer’s progress.

- Disperse pressure and reduce sinking: The chain plate increases the ground contact area, which can effectively reduce the unit pressure and increase the buoyancy of the bulldozer on soft ground.

- Protect the track links and chassis parts: The chain plate can reduce the impact on other components of the chassis and extend the life of the whole machine.

Therefore, choosing a high-quality track shoe can not only improve the performance of the bulldozer, but also save maintenance costs in long-term operation.

GFM track shoes pursue the ultimate in design and manufacturing. From material selection to processing, every process reflects our persistence in quality.

- High-quality manganese steel or alloy steel material: high-strength wear-resistant steel plate is used, which has excellent impact resistance and wear resistance, and has a longer service life.

- Heat treatment strengthening process: We have improved the overall strength and hardness of the chain plate through the dual processes of whole plate quenching and tempering and high-frequency quenching of the track surface, especially stable performance under high-frequency use environment.

- Standard hole spacing and thickness design: Adapt to most mainstream bulldozer models on the market (such as Komatsu, Caterpillar, Shantui, etc.), and also support non-standard customization.

- Wide track design optional: Provide widened chain plate solutions for special operation scenarios such as swamps and high water areas.

- Anti-rust coating treatment: All chain plates are treated with anti-corrosion coating before leaving the factory, suitable for various extreme weather environments.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Durable & Long-Lasting: Built from high-quality steel to withstand tough jobs.

- Enhanced Stability: Excellent traction for safe operation on any terrain.

- Extended Lifespan: Reduces wear and protects your undercarriage.

- Rust-Resistant: Coated for reliable performance in harsh conditions.

- Cost-Effective: Lowers maintenance costs with superior durability.

- Versatile: Perfect for rock, mud, sand, or soft ground.

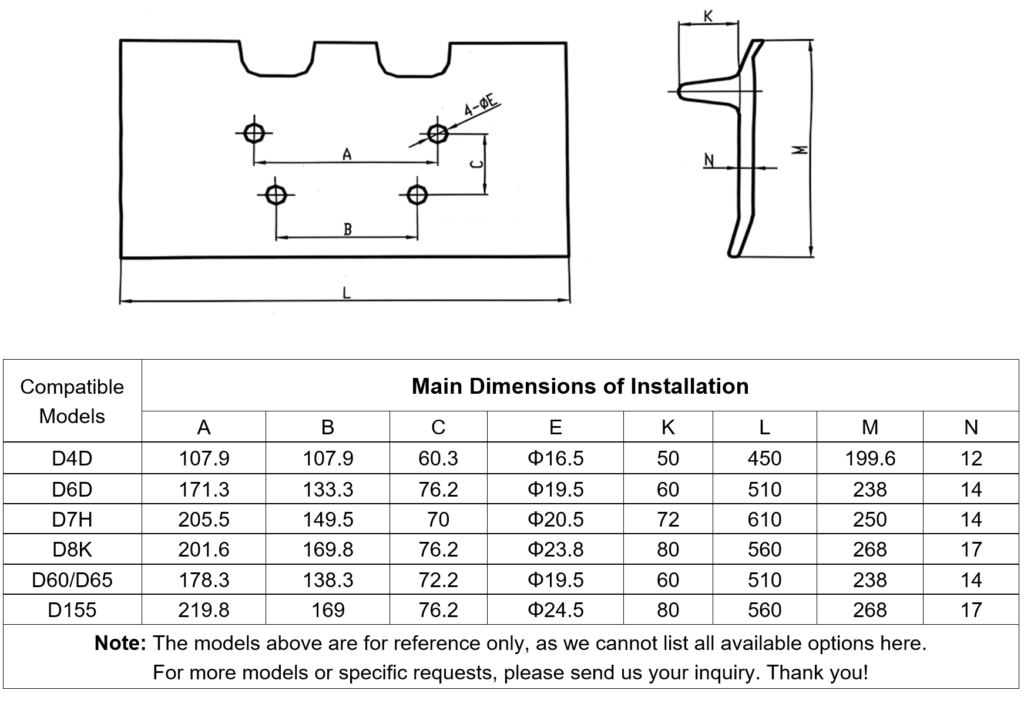

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

As a bulldozer undercarriage parts manufacturer with more than ten years of rich experience, GFM has accumulated rich experience in the field of bulldozer track systems. We have built our own production base, covering an area of more than 10,000 square meters, with advanced facilities such as forging equipment imported from Germany, CNC machining centers, automatic heat treatment lines, and spray anti-corrosion lines.

We have a complete quality control process, from raw material testing, dimensional tolerance control, metallographic analysis, to pre-assembly strength testing, to ensure that each chain plate meets high standards before leaving the factory.

Provide one-to-one customized services to meet your special needs

At GFM, we are well aware that different projects have different needs. Therefore, we provide professional customized services:

- Size customization: According to customer drawings or samples, the required hole spacing, width, thickness and other parameters can be accurately produced.

- Material upgrade: Provide different grades of alloy steel options to meet high-intensity operation scenarios.

- Surface treatment customization: Treatment methods such as galvanizing, electrophoresis, and anti-rust oil can be selected according to needs.

- Small batch proofing and batch delivery: support fast sample proofing, delivery within 3-7 days; batch orders can be flexibly scheduled according to delivery requirements.

Our technical team will assist you from design to finished product, follow up the whole process, and truly “build for customers”.

Whether you are an equipment dealer, terminal construction unit, or equipment maintenance manufacturer, GFM track shoe manufacturers welcomes you to consult with drawings and samples, and we will provide you with professional advice and fast quotation services. Choosing GFM means choosing strength and reliability!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Track Idler

High Quality Excavator Track Idler Manufacturers

- UNDERCARRIAGE

Top Roller Excavator Carrier Roller Factory