Excavator Top Roller CAT 320 Carrier Roller Supplier

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM’s excavator top rollers for CAT 320 excavators are precision-engineered to deliver unmatched durability and smooth undercarriage operation. Designed with ISO-certified manufacturing processes, these carrier rollers seamlessly integrate with CAT 320’s track system while outperforming OEM standards in extreme working conditions.

• Military-Grade Materials

Forged from heat-treated alloy steel and triple-sealed bearings, top rollers resist deformation under loads up to 18% heavier than industry averages – ideal for mining and quarry operations.

• Smart Friction Reduction

Reduces lateral friction loss by 35%, extending the chain life to 2,200+ working hours, significantly reducing your hourly operating costs.

• Climate-Adaptive

The special coating process has passed the salt spray test and can operate stably in an environment of -40℃ to 75℃, suitable for polar exploration and tropical engineering projects.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Long-Lasting Durability: Crafted from high-grade, wear-resistant steel for maximum strength and extended lifespan.

- Sealed and Lubricated: Fully sealed design keeps out dirt, water, and contaminants, minimizing wear and maintenance.

- Smooth Operation: Precision-engineered to provide efficient and stable support for the upper portion of the track.

- Corrosion Resistance: Corrosion-resistant surface treatments ensure reliable operation in harsh environments.

- Fits Various Models: Designed to fit a wide range of excavator and bulldozer models for various applications.

- Proven Toughness: Tested to perform reliably under extreme conditions, reducing downtime and increasing productivity.

At GFM Factory, our carrier rollers are built to optimize your machinery’s performance, ensuring smoother track operations and extended equipment life.

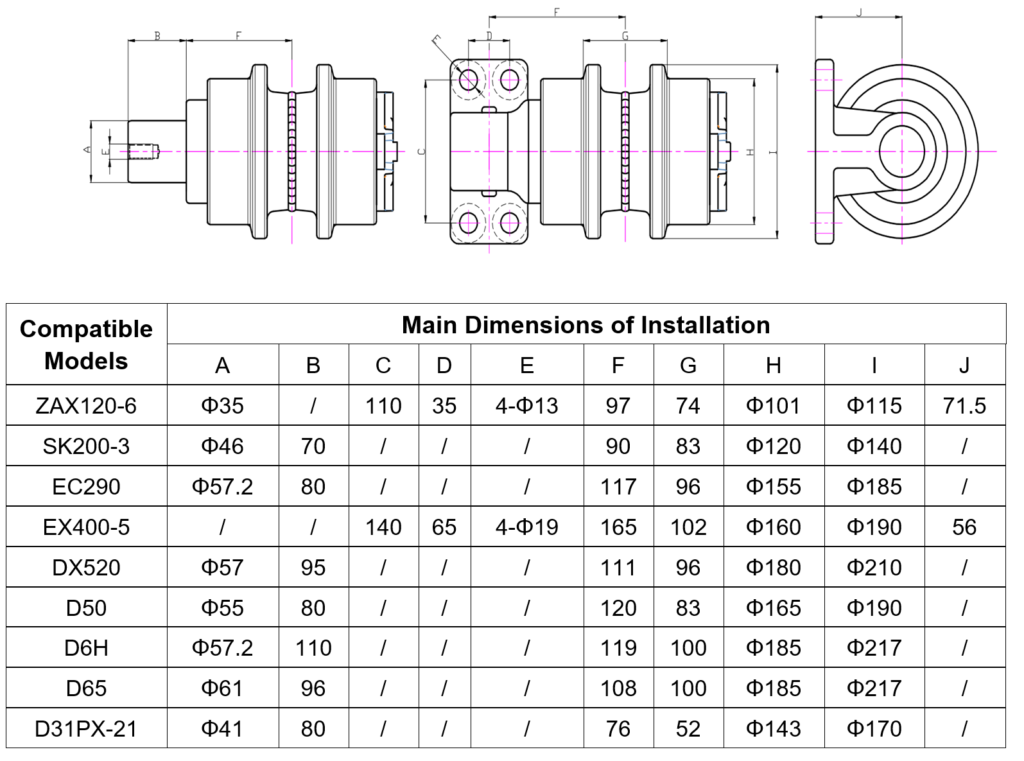

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM has been wholesale carrier rollers for 14 years. The GFM factory is equipped with a full-process CNC machining center and a spectrum detector to ensure that the chemical composition and tensile strength (≥1200MPa) of each roller meet the standards. The production line is ISO 9001:2015 certified and uses the MES system to achieve digital quality control from raw material traceability to finished product packaging. The product has passed the CE certification and supports the one-stop supply needs of OEM/aftermarkets in North America, Southeast Asia and other regions.

As the world’s top excavator carrier roller supplier, we provide CAT 320 support wheels with:

√ digital workshop: using laser cutting machine and ABB welding robot to ensure ±0.05mm dimensional tolerance

√ Triple quality inspection system: raw material spectrum analysis → assembly process pressure test → finished product 72-hour simulated working condition verification

Why choose GFM as your carrier roller supplier?

- High quality guarantee: All drag chain wheel products are made of high-quality materials and are rigorously tested to ensure stable performance in various harsh environments.

- Technical advantages: Years of industry experience and professional team support make our products lead the industry in wear resistance and strength.

- Flexible customization: Support mass production and personalized customization services to meet the diverse needs of customers.

- Perfect service: From product consultation to after-sales support, GFM always takes customer satisfaction as the core and provides a full range of service guarantees.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Sumitomo SH200 Excavator Top Roller

- UNDERCARRIAGE

Bulldozer Swamp Track Shoe Supplier

- UNDERCARRIAGE

Bulldozer Track Chain Manufacturer

- UNDERCARRIAGE

High Quality Excavator Track Shoe Manufacturer