High Quality Sany SY485 Excavator Track Idler Suppliers

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

In an excavator’s undercarriage system, the track idler plays a critical role in maintaining track tension and guiding the track’s movement. The SY485 excavator track idler developed by GFM is engineered specifically for demanding jobsite conditions. Made from high-strength alloy steel, it delivers exceptional wear resistance and structural stability, even in complex environments such as mining and heavy earthworks.

Critical Component Role:The track idler plays a vital role in an excavator’s undercarriage system by maintaining track tension and guiding track movement, ensuring stable machine operation.

Made from High-Strength Materials:GFM’s SY485 track idler is made of high-strength alloy steel, offering excellent wear resistance and structural stability, capable of withstanding harsh environments such as mining and earthmoving.

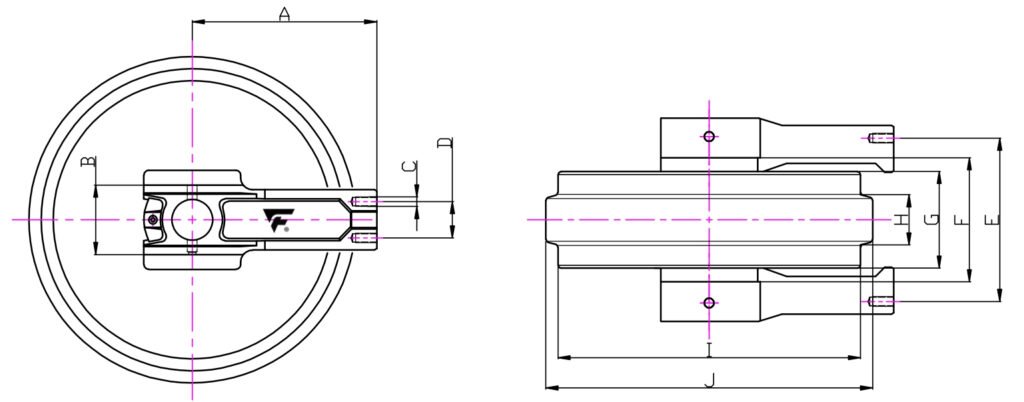

Precisely Matched Design:Manufactured strictly according to SY485 model dimensions and technical requirements, ensuring perfect fit, reducing equipment failure and maintenance frequency.

Optimized Structure to Reduce Wear:Unique structural design and material hardness help minimize vibration and track derailment risks, improving operational efficiency and service life.

Built to Original Equipment Quality:Each idler is manufactured to adhere strictly to original equipment quality specifications, ensuring reliable performance and long service life for your machinery.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Specifications

Product Models

Production Process

In order to ensure that each guide wheel meets high standards, we adopt a strict process:

- Raw material inspection: Select raw materials that meet international standards, and each batch of incoming materials is tested.

- Precision machining: CNC machine tools are used to process each component to ensure that the size and accuracy meet the requirements.

- Surface treatment: Special processes are used for surface spraying and hardening treatment to effectively prevent wear.

- Assembly and debugging: After the components are assembled, they are fully debugged to ensure overall coordinated operation.

- Quality inspection: Finally, strict performance and durability tests are carried out, and only qualified products can be shipped.

Each step of the process strictly follows international standards to ensure the high performance and long life of the products, so that customers can use them with peace of mind.

Packaging and Shipping

Factory Advantages

Quanzhou GFM Machinery Co., Ltd. has been focused on manufacturing excavator and bulldozer parts since 2011. With over 14 years of industry experience, GFM is a recognized manufacturer and supplier of high-performance undercarriage components.

- Extensive Product Range:GFM provides a full range of undercarriage components, including track rollers, carrier rollers, idlers, sprockets, track links, track shoes, bolts, nuts, pins, bushings, buckets, and bucket teeth.

- Mature Production Capabilities:The factory is equipped with casting, heat treatment, and precision machining lines. Each production step is standardized and well-managed to ensure consistent quality and efficiency.

- Standardized Quality Control:All products come with at least 1-year or 2,000-hour quality guarantee. The entire production process complies with strict ISO-level standards and includes quality checkpoints throughout each stage.

- Ample Inventory and Prompt Supply:GFM maintains an inventory of over 1,000 part numbers, covering most common models. This supports prompt order fulfillment and minimizes downtime for customers.

- Wide Brand Compatibility:GFM’s components are compatible with most mainstream brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, SANY, Liugong, XCMG, Shantui, and others—ensuring wide market applicability.

- Competitive Factory-Direct Pricing:All products are directly supplied from GFM’s manufacturing facility, offering strong cost advantages without middlemen.

- Serving Global Markets:With years of stable performance and trustworthy service, GFM’s products are now exported to Southeast Asia, the Middle East, Africa, and other international markets. Among global excavator idler suppliers, GFM has earned a solid reputation for reliability and professionalism.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Track Idler

Kato HD700 Excavator Track Idler

- Track Idler

John Deere 330 Excavator Track Idler

- Track Idler

Sumitomo SH210 Excavator Idler Roller