Hitachi ZAX870 Excavator Sprocket Wheel YA00001980 4430291

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

When a heavy equipment such as Hitachi ZAX870 is operating in complex working conditions, each chassis component is subjected to high-intensity impact and wear. Among them, the sprocket, as a key link in transmitting power, determines the travel efficiency and stability of the whole machine. GFM wholesales excavator sprocket wheel suitable for Hitachi ZAX870, which are high-quality accessories tailored to meet the needs of heavy-load, high-frequency, and complex terrain operations, helping the equipment to operate stably and effectively.

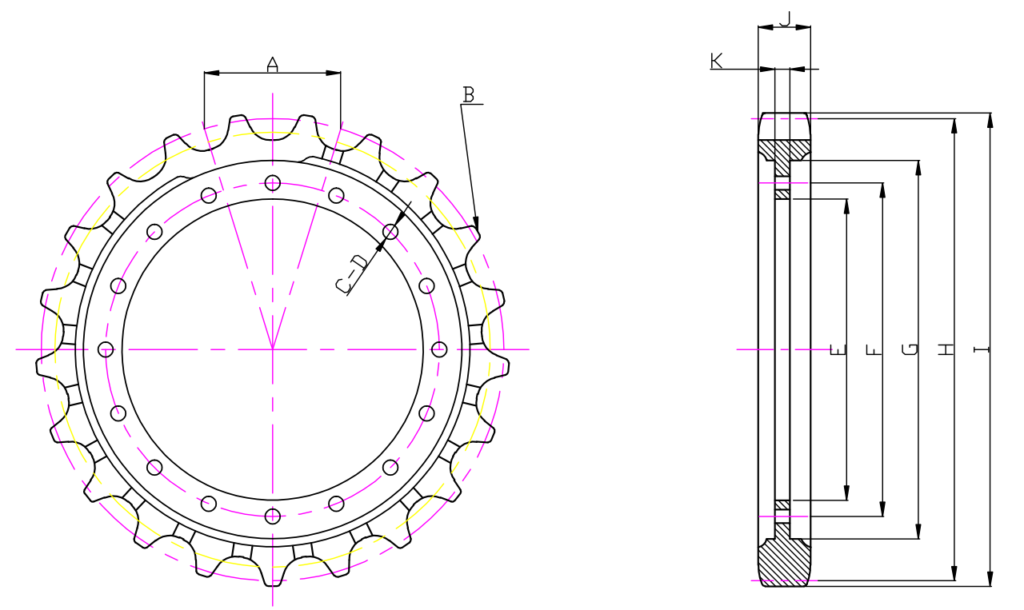

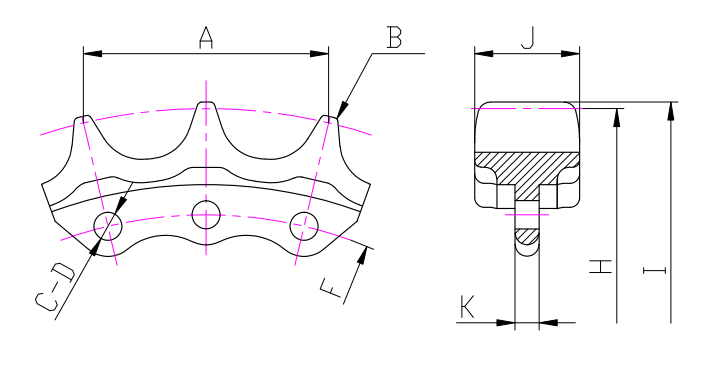

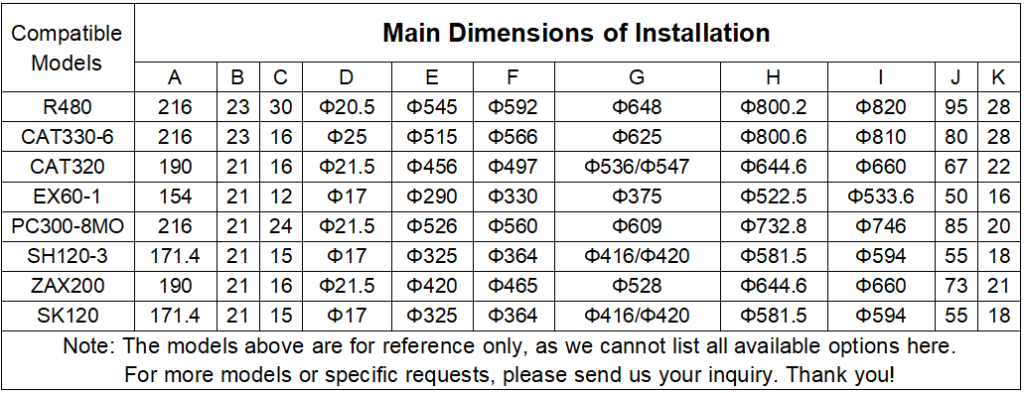

Our sprockets are strictly developed and manufactured according to the original factory parameter standards of Hitachi ZAX870 to ensure that they are fully compatible with the original machine system and can be installed and used without additional adjustments. The core dimensions such as the number of teeth, installation hole spacing, and center hole diameter of the product are accurately matched to avoid installation difficulties or abnormal operation due to tolerance mismatch.

The sprocket is forged with high-strength alloy steel as a whole, and undergoes multiple heat treatment processes such as quenching and tempering, surface high-frequency quenching, etc., so that it has excellent wear resistance and impact resistance. The chain tooth part is specially hardened to effectively extend the service life, and the tooth shape can be kept intact even in high-wear conditions such as sand, gravel, and mud.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator or Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Exceptional Durability: Made from premium materials to endure heavy-duty operations and resist wear over time.

- Perfect Fit: Engineered for precise alignment with excavator and bulldozer track systems, ensuring optimal performance.

- High Load Capacity: Designed to withstand intense workloads while maintaining strength and stability.

- Effortless Operation: Ensures smooth engagement with the track chain, reducing vibration and boosting efficiency.

- All-Weather Performance: Built to resist rust, moisture, and extreme temperatures, ensuring reliability in any environment.

Specifications

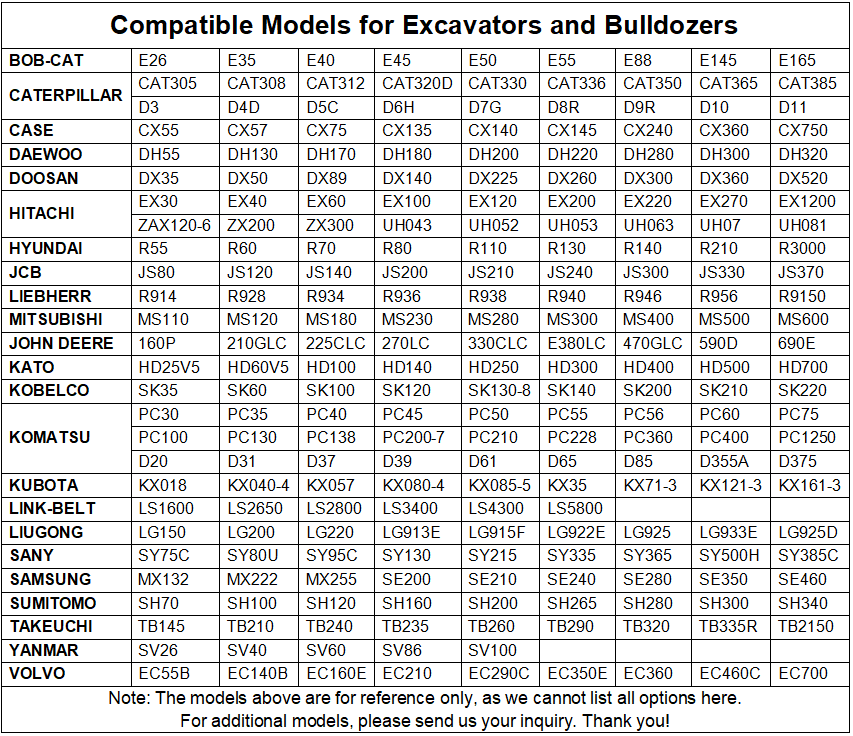

Product Models

Production Process

GFM adheres to the manufacturing concept of “process is quality” and strives for excellence in every detail in sprocket production. Our process includes:

- Raw material screening: Select high-quality alloy steel materials that meet ISO standards to ensure basic performance;

- Forging: Use precision die forging technology to ensure that the sprocket blank structure is dense and crack-free;

- CNC machining: Use CNC machining center for tooth cutting throughout the process to ensure installation accuracy;

- Heat treatment and tempering: Unify temperature control and carburizing depth to form an excellent wear-resistant shell and tough inner core;

- Final inspection: Use a three-coordinate measuring instrument to check the dimensional accuracy one by one to ensure zero error before leaving the factory.

These processes not only ensure the long-term durability of the sprocket, but also ensure its smooth operation and low noise performance when it cooperates with the track section.

Packaging and Shipping

Factory Advantages

GFM excavator sprocket manufacturers has been focusing on the manufacturing of excavator chassis parts for more than 15 years. It has more than 18,000 square meters of modern factory buildings, equipped with dozens of high-precision processing equipment and heat treatment production lines, and produces more than 200,000 sprockets per year.

Our R&D team consists of many mechanical engineers with more than 10 years of experience. They have rich customized development capabilities and can provide directional sprocket optimization design solutions according to different brands and models and special application scenarios (such as cold areas, saline-alkali areas, etc.).

Customized services we provide:

- Size customization: The chain teeth, hole spacing and other dimensions can be precisely customized according to the drawings or samples provided by the customer.

- Material customization: Different grades of alloy steel or quenching and tempering solutions can be selected according to the working conditions.

- Surface treatment customization: Anti-rust treatments such as black phosphating, electrophoretic spraying, and environmentally friendly coating can be selected.

- Small batch proofing: Support fast proofing services, and the first piece can be delivered within 7 days at the earliest.

Personalized logo: Brand LOGO and batch code can be laser engraved for easy traceability and brand promotion.

GFM has passed the ISO9001 quality management system certification and is equipped with a complete factory inspection process to ensure that every sprocket product delivered to customers can withstand the test of the market.

If you are looking for a reliable, durable, and precisely adapted sprocket for ZAX870, GFM will be your best choice. Not only is the product quality trustworthy, we are more willing to become your long-term cooperative excavator undercarriage parts supplier through quick response and flexible customization.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Excavator Chain Wheel Sprocket for Excavator CAT E385

- UNDERCARRIAGE

Wholesale Excavator Track Group Assembly Manufacturer