Hyundai R55 R60 Mini Excavator Track Chain Suppliers

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Among excavator accessories, the chain, as one of the core components of the chassis, bears the heavy responsibility of machine walking and operation stability. For the two hot-selling small excavators, Hyundai R55 and R66, choosing a wear-resistant, highly matched and long-life chain can not only reduce maintenance costs, but also significantly improve work efficiency.

As an excavator parts factory with many years of experience in manufacturing engineering machinery parts, GFM focuses on the production of high-precision and high-strength excavator track chain, and provides high-quality customized chain solutions especially for the Hyundai R55 and R66 series. If you are looking for a truly “fitting” chain, GFM is definitely a trustworthy partner.

Why choose GFM Hyundai R55/R66 chain?

Precise adaptation, professional matching of original factory standards

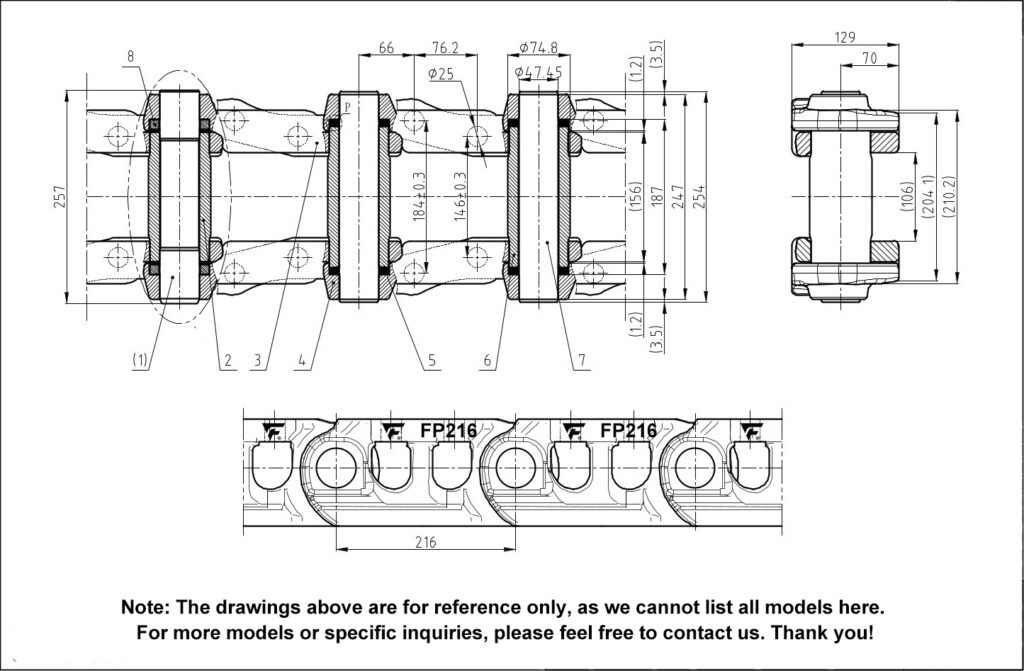

The chain provided by GFM is repeatedly tested and designed according to the structural parameters of the Hyundai R55 and R66. From the pitch of the chain link, the diameter of the pin shaft, the inner width size to the overall tensile strength, each link strictly controls the error to ensure seamless adaptation with the original chain rail system. We use advanced three-coordinate measuring machines to precisely test the dimensions of each batch of chains.

Reliable materials and durable

In actual operation, modern R55 and R66 chains face extreme environments such as soil and rock impact, cement hard ground friction, high temperature and high humidity. To this end, GFM chains use high manganese alloy steel as the base material, and the surface is subjected to multi-layer heat treatment + overall tempering + deep quenching process to significantly improve the tensile strength, impact resistance and wear resistance of the chain.

Full process quality control, from raw materials to shipment

At GFM, we always put “quality” first. The production process of each chain strictly implements the ISO 9001 quality management system. We use CNC special machines to achieve high-precision chain link processing, with an error control within ±0.05mm, and are equipped with fatigue test benches and high-load simulation test systems to ensure that the chain can cope with long-term high-intensity operations.

Product Description

- Technique: Forging

- Raw Material: 35MnBH/40Mn2

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- High Durability– Built with premium alloy steel to withstand heavy use.

- Perfect Fit– Precision-crafted for seamless compatibility with major excavator brands.

- Enhanced Strength– Heat-treated for superior hardness and wear resistance.

- Corrosion Resistant– Special coating protects against rust in tough conditions.

- Smooth Operation– Low friction design ensures quiet and efficient performance.

- Quick Installation– Easy to assemble, saving time and reducing downtime.

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM has been focusing on the manufacturing of engineering machinery parts for more than 10 years. It has a complete production line and an independent R&D team. The factory covers an area of more than 12,000 square meters and produces more than 200,000 excavator chassis parts of various types annually.

Our customers are spread across more than 30 countries around the world, covering agents, equipment leasing companies, terminal owners and other user types. Long-term cooperative customers include excavator whole machine after-sales brands from South Korea, Türkiye and the UAE.

In addition, GFM also actively participates in international construction machinery exhibitions such as BICES and bauma CHINA, continuously updating technology and application trends to ensure that our products are always at the forefront of the industry.

Worry-free installation and after-sales, more assured cooperation

We provide detailed installation instructions, and can also provide related undercarriage parts such as sprockets, track shoes, and track rollers to assist customers in quickly completing the replacement of the entire machine chassis.

In terms of after-sales, GFM promises that during the warranty period, if the chain breaks or fails due to product quality problems, it will be replaced free of charge, and technical support and remote fault diagnosis services will be supported.

A good excavator track link assy is not just an accessory, it is a guarantee of stable operation and a tool for cost control. GFM is committed to providing customers with accurate, durable, and personalized modern R55/R66 excavator chain solutions to help every user save worry, money, and effort at the construction site.

If you are looking for an experienced, customized, and internationally service-capable chain manufacturer, you may wish to contact GFM. We are happy to work with you to build a solid foundation for engineering efficiency!

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

ZAX870 Excavator Track Roller Supplier 4473720

- UNDERCARRIAGE

PC30-2 Bottom Roller Excavator Track Roller Manufacturer