Komatsu D375 Sprocket Segment Group 195-27-33110 195-27-3311

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

In the daily operation of the excavator, the sprocket segment group is one of the indispensable core components. For large crawler bulldozers or excavation equipment such as Komatsu D375, the quality of the sprocket segment group directly affects the stability, transmission efficiency and operating life of the whole machine. GFM has been focusing on the manufacture of excavator chassis accessories for many years and is committed to providing sprocket segment groups suitable for Komatsu D375, providing flexible and high-quality customized services to meet the diverse needs of global customers.

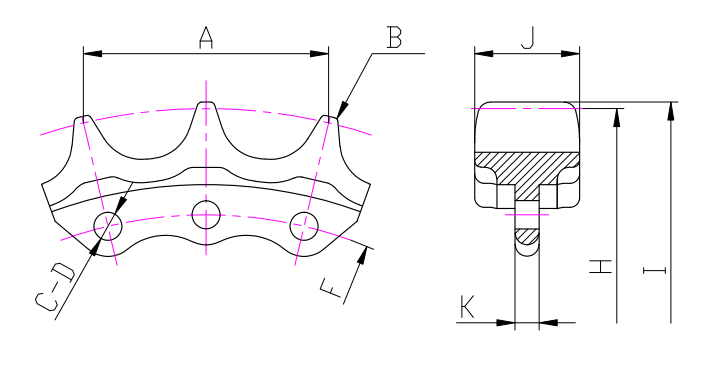

The sprocket segment for bulldozer Komatsu D375 is a high-strength transmission component designed by GFM according to the original factory drawing standards and manufactured by CNC machining. It is mainly used to drive the crawler forward or backward. It is composed of a combination of multiple gear rings, surrounding the drive wheel hub, and meshing with the crawler pin sleeve through teeth to achieve the forward power transmission of the equipment.

This type of large equipment usually faces challenges such as high loads, harsh terrain, and high-intensity work, so it has very high requirements for the material, process, and wear resistance of the sprocket segment group.

Whether in a large quarry, open-pit coal mine or highway construction site, the Komatsu D375 needs to operate continuously at high intensity. Equipped with high-quality sprocket segments, it can bring the following advantages:

- Extend the service life of the track: high-quality gear rings reduce the impact force of the chain and track pins.

- Reduce maintenance frequency and cost: excellent wear resistance means less replacement and repair.

- Improve transmission efficiency: precise processing dimensions make the whole vehicle run smoother and more fuel-efficient.

- Adapt to a variety of complex working conditions: including muddy ground, sandy and gravel sections, high temperature and high humidity environments.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Exceptional Durability: Made from premium materials to endure heavy-duty operations and resist wear over time.

- Perfect Fit: Engineered for precise alignment with excavator and bulldozer track systems, ensuring optimal performance.

- High Load Capacity: Designed to withstand intense workloads while maintaining strength and stability.

- Effortless Operation: Ensures smooth engagement with the track chain, reducing vibration and boosting efficiency.

- All-Weather Performance: Built to resist rust, moisture, and extreme temperatures, ensuring reliability in any environment.

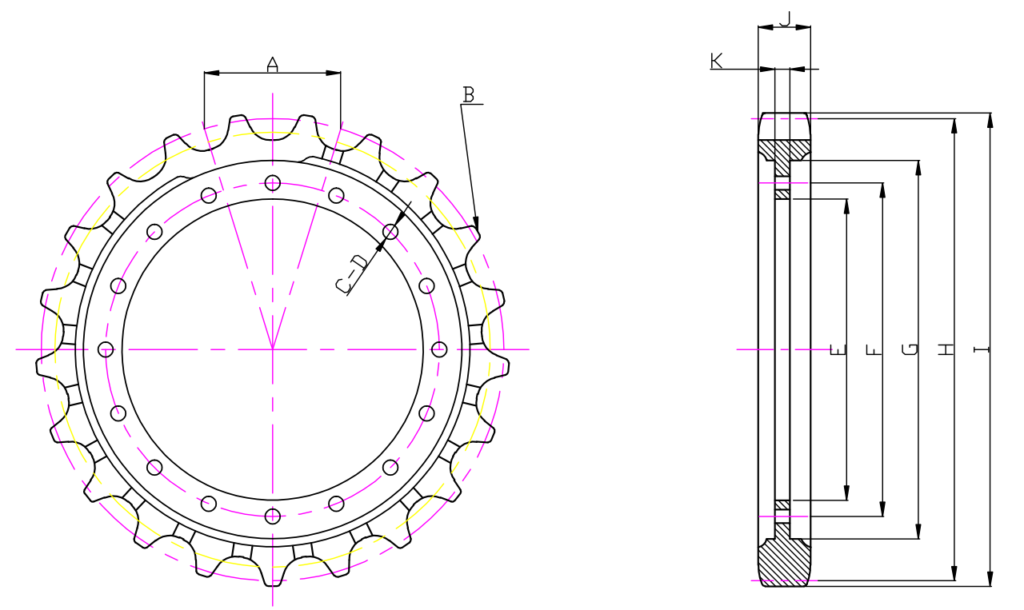

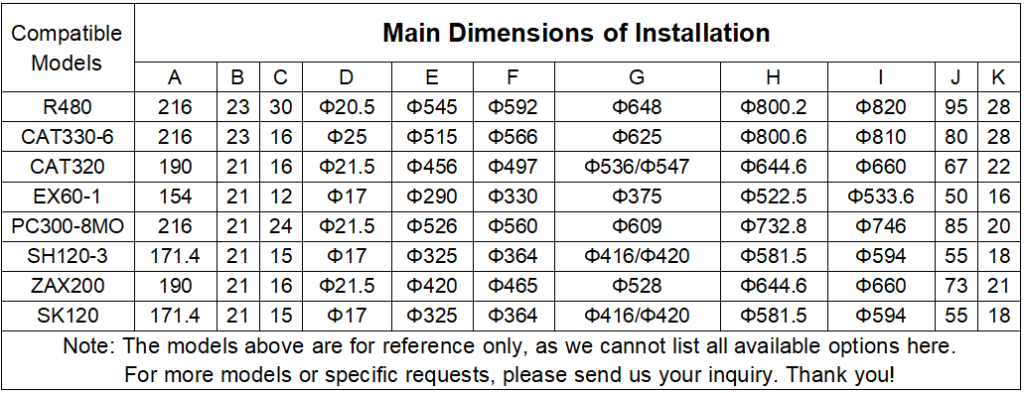

Specifications

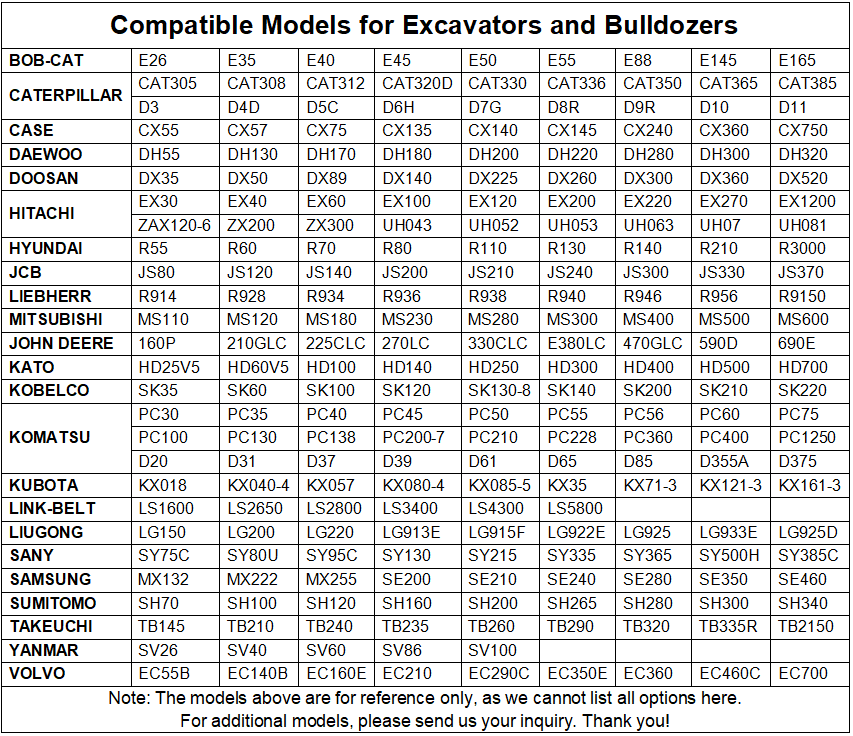

Product Models

Production Process

Raw material selection and chemical composition control

- We strictly select high-quality alloy steel from well-known steel mills at home and abroad, and the chemical composition is tested by a spectrometer to ensure that the content of elements such as C, Cr, and Mo is accurate and stable.

High-temperature forging and preliminary shaping

- Forging at a high temperature of more than 1,200 ℃ makes the internal grains refined and the structure dense. After preliminary shaping, it is put into storage for inspection.

Multi-stage heat treatment strengthening

- Normalizing: 850–900 ℃ uniform heating to refine the metal structure.

- Quenching: Rapid cooling under oil cooling medium, the hardness is increased to HRC 48–52.

- Double tempering: 580–620 ℃ for more than 2 hours to eliminate internal stress and improve toughness.

CNC precision machining and online measurement

- Imported five-axis linkage CNC machine tools are used, and the machining tolerance is controlled at ±0.02 mm. Critical dimensions are tested online using a three-coordinate measuring machine to ensure that every piece leaves the factory with precision.

Packaging and Shipping

Factory Advantages

As a leading bulldozer parts manufacturer, GFM’s sprocket and gear products have significant technical advantages. We use a sophisticated manufacturing process to ensure the dimensional accuracy and durability of each sprocket and tooth plate. The use of advanced heat treatment technology enhances the hardness and wear resistance of the product, making it suitable for high load and long-term heavy-load work. In addition, our products are suitable for various models of bulldozers and excavators, with wide compatibility and customization capabilities to meet the diverse needs of customers.

Why choose GFM sprockets and segments?

When you choose GFM’s bulldozer sprockets and toothed segments, you will get first-class quality and reliable performance. Our production base has modern manufacturing facilities and a strict quality control system. From raw material procurement to finished product inspection, every process is carefully controlled to ensure that each product meets international standards. With many years of industry experience and rich technical accumulation, our products are widely acclaimed in the global market and are widely used in construction, mining, road construction and other fields.

Since its establishment, GFM has always focused on the research and development and production of excavator and bulldozer chassis parts, especially in sprocket segment groups, track shoes, supporting wheels and other transmission system parts with more than 10 years of manufacturing experience. Our advantages are not only in product quality, but also in production management and technical services:

- Modern factory: equipped with automated heat treatment lines, high-precision machining centers, shot peening and coating workshops.

- Annual production of over 100,000 sprocket segments: continuous supply to global customers without chain break risk.

- Passed ISO9001 and CE dual certification: perfect quality management system, export meets global standards.

- Serving customers in more than 50 countries: from Southeast Asia, the Middle East to South America, extensive application cases have accumulated rich practical feedback.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Track Link

Bulldozer Track Chain Manufacturer

- Track Idler

High Quality Excavator Track Idler Manufacturers