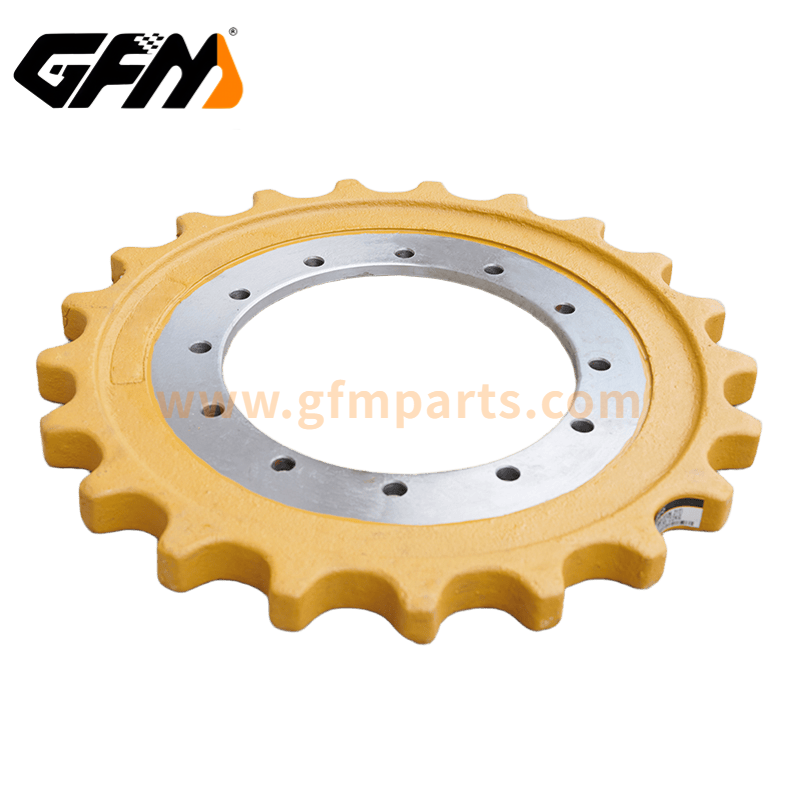

Komatsu PC60-7 Mini Excavator Sprocket

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

As the core drive component of Komatsu PC60-7 series small excavators, our mini excavator sprocket is forged with high-strength alloy steel and is specially optimized for the speed, torque and load characteristics of this model. The sprocket tooth shape meshes perfectly with the chain, which can maintain smooth operation under high load and long working hours, effectively extending the life of the travel system. Whether you are doing daily municipal construction or fine pipe trench work, this sprocket can achieve smooth start and stable propulsion, making your PC60-7 perform better.

- Preferred materials: alloy steel is used, and after multiple processes of deep quenching + tempering treatment, the surface hardness can reach HRC55 or above, with excellent internal toughness, strong impact resistance, and more than 30% improvement in wear resistance.

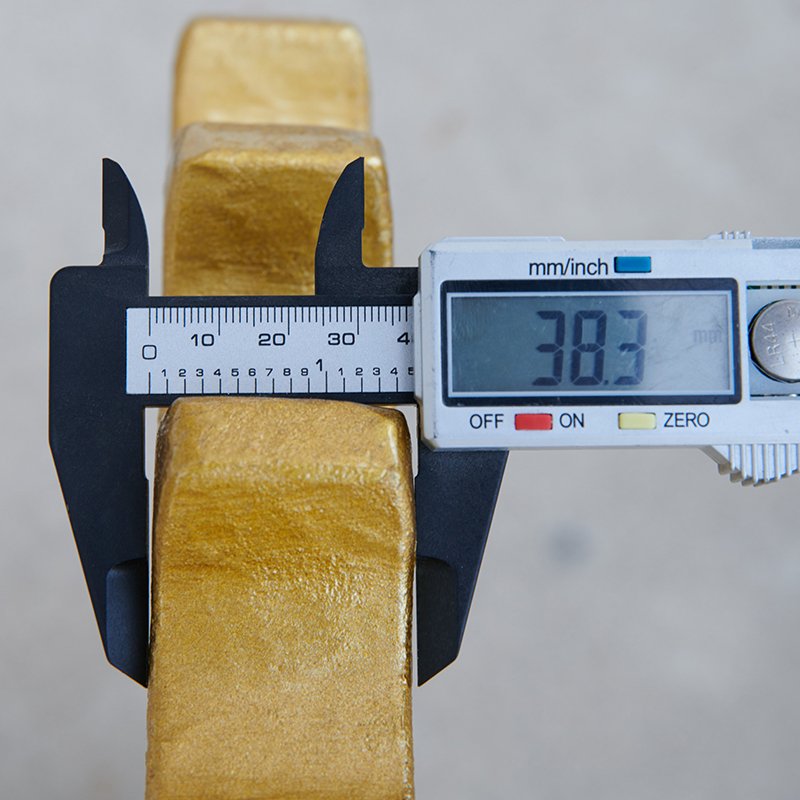

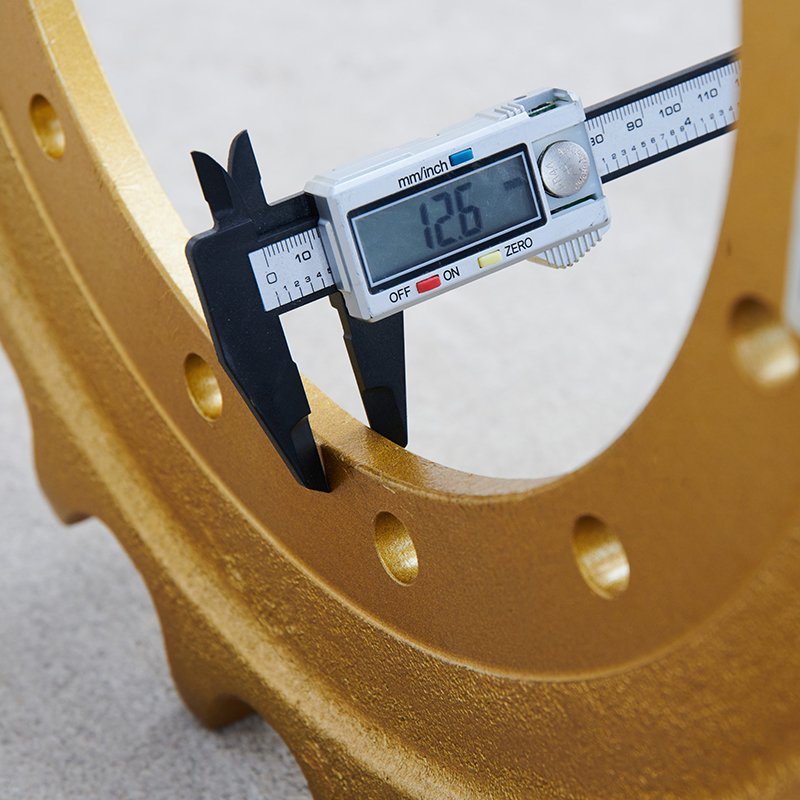

- High-precision tooth shape: precision CNC machining, the tolerance of tooth top, tooth root and tooth surface is controlled within ±0.02mm; the profile and roughness of each tooth surface are strictly tested to ensure smooth engagement between the chain and sprocket and lower noise.

- Surface treatment: high-temperature nitriding and phosphating dual processes are adopted to further improve the surface hardness and corrosion resistance, enhance the antioxidant capacity, and adapt to a variety of operating environments.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator or Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Exceptional Durability: Made from premium materials to endure heavy-duty operations and resist wear over time.

- Perfect Fit: Engineered for precise alignment with excavator and bulldozer track systems, ensuring optimal performance.

- High Load Capacity: Designed to withstand intense workloads while maintaining strength and stability.

- Effortless Operation: Ensures smooth engagement with the track chain, reducing vibration and boosting efficiency.

- All-Weather Performance: Built to resist rust, moisture, and extreme temperatures, ensuring reliability in any environment.

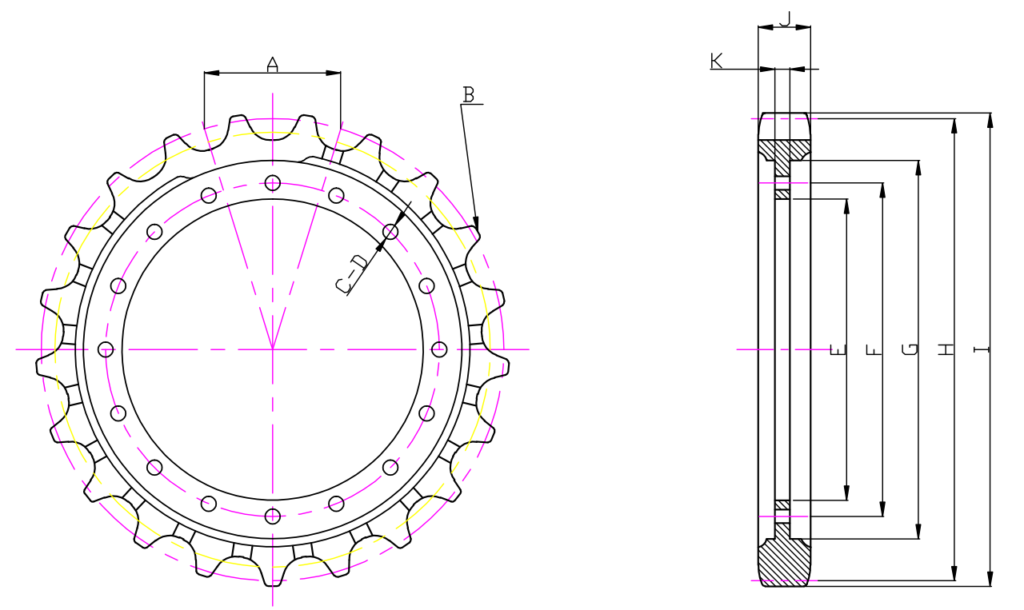

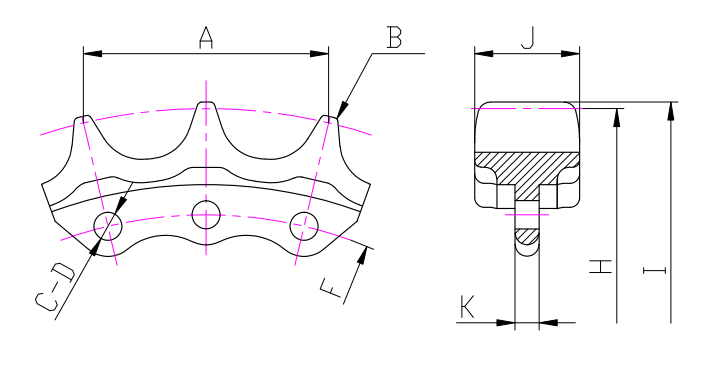

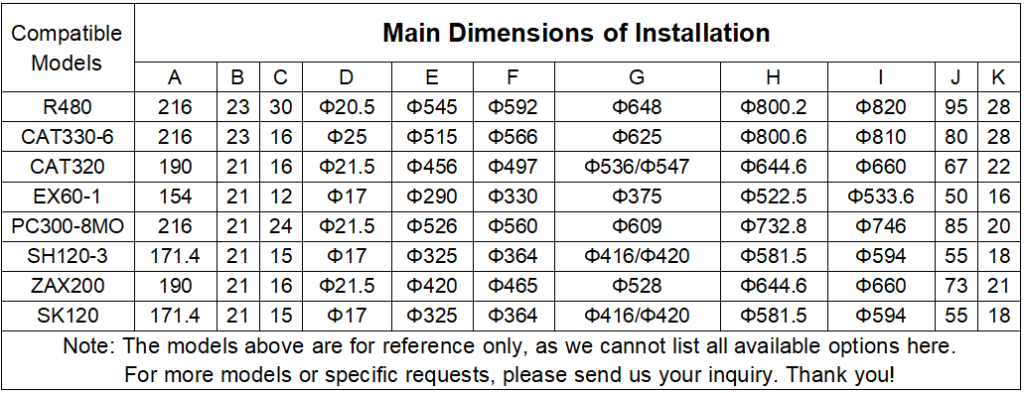

Specifications

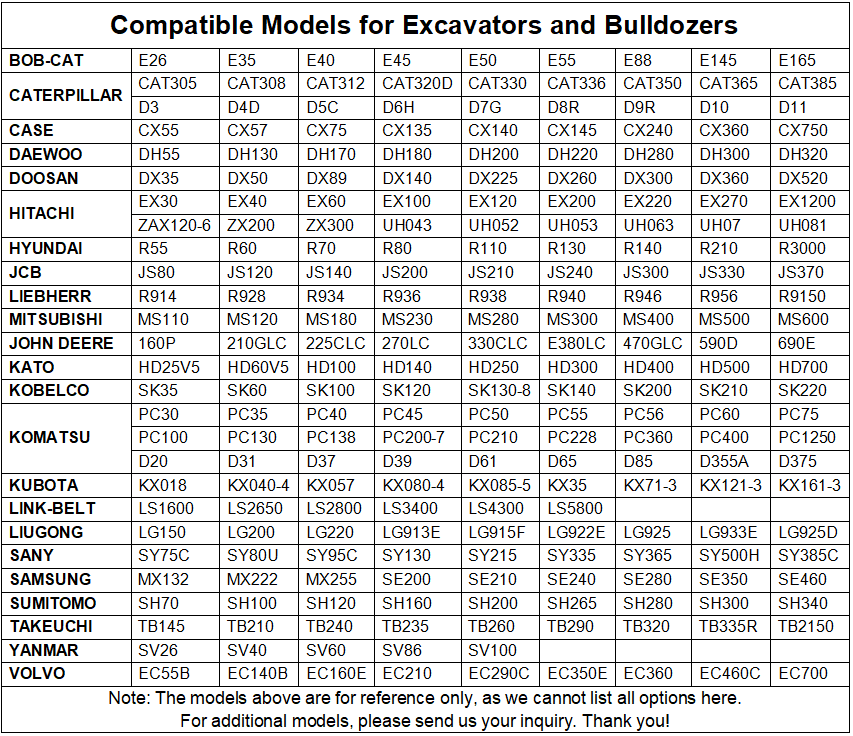

Product Models

Production Process

- Forging blank: high-quality alloy steel bars are selected for isothermal forging to ensure that the internal structure is dense and uniform.

- Heat treatment: first quenching and then tempering, and then temperature tempering to eliminate internal stress; the balance of hardness and toughness makes the sprocket less likely to crack under high torque environment.

- CNC machining: precise cutting is carried out through the five-axis linkage CNC machining center, and each tooth surface is repeatedly polished to ensure the tolerance range and surface finish.

- Surface strengthening: high-temperature nitriding or phosphating treatment, combined with shot peening to eliminate residual stress and improve fatigue life.

- Quality inspection: equipped with advanced inspection equipment such as three-coordinate, hardness tester, profilometer, etc., full inspection of multiple indicators such as size, hardness, surface quality, magnetic particle flaw detection, etc.

- Dynamic balance test: The assembly test bench simulates the operation of the actual vehicle, detects vibration and temperature rise, and ensures that the products shipped meet the use requirements 100%.

Packaging and Shipping

Factory Advantages

As a leading excavator parts supplier, GFM is committed to providing a comprehensive range of excavator sprockets for a variety of popular brands and models, and providing customized solutions to meet your unique needs. Our advanced production facilities are equipped with advanced CNC machine tools and quality assurance systems to ensure that each sprocket meets the specifications of the original equipment manufacturer (OEM).

Our team of experts works closely with customers to optimize sprocket design, improve wear resistance and operating efficiency. Choosing GFM, you will benefit from decades of manufacturing expertise, responsive customer support and commitment to innovation to ensure that your excavator can maintain optimal performance even in the most demanding environments.

- Size and tooth shape customization: According to the disassembled machine samples or 3D drawings provided by the user, the corresponding mold can be quickly developed to support non-standard tooth number, tooth pitch and aperture size customization.

- Material deep customization: Different alloy formulas such as 42CrMo, 50CrMo4, as well as surface chrome plating, hard aluminum oxidation treatment, etc. can be selected to meet special environmental requirements.

- LOGO and packaging personalization: Support printing of customer-exclusive trademarks or QR codes on sprockets and packaging boxes to enhance brand recognition; packaging can be selected from wooden boxes, cartons or pallet bundling according to customer requirements.

Practical Guide to Installation and Maintenance

- Pre-installation inspection: Clean the sprocket mounting surface and chain guide rail to ensure that there are no foreign objects; check the tension of the chain, and it is recommended to reserve 3-5mm vertical.

- Installation steps: First manually insert the sprocket tooth groove, and then tighten the center bolt with a torque wrench according to the specified torque (recommended 350-400N·m); then start the machine and idle at low speed for 2 minutes to check the smoothness of operation.

- Daily maintenance: Add chain guide lubricant every 50 working hours to avoid dry grinding; check the wear depth of the sprocket regularly (100 hours), and replace it in time if the wear exceeds 0.5mm.

- Troubleshooting: If abnormal noise or poor meshing occurs, first check the looseness of the sprocket bolts, the tightness of the chain and the wear of the sprocket tooth surface; if necessary, remove the sprocket and use a four-coordinate measuring instrument to detect the tooth profile deviation.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

XCMG XE370 Excavator Sprocket Supplier

- UNDERCARRIAGE

CAT E305.5 Excavator Chain Wheel

- UNDERCARRIAGE

Excavator and Bulldozer Sprocket and Segment