Komatsu PC100 Bucket Tooth Pin

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

When choosing bucket tooth pin for Komatsu PC100 excavator, you need to pay attention to the quality, durability and precision of the product. GFM has been focusing on the manufacturing and production of excavator accessories for many years and has accumulated rich experience to ensure that every product meets high standards.

In order to ensure the practicality of the excavator bucket teeth pin products, we have adopted a number of specific measures to improve durability and adaptability during the design and manufacturing process. First of all, we select high-quality raw materials. In the processing link, we use precision milling and grinding technology to make every detail of the product meet the standard size requirements. In addition, we also carry out special treatment on the surface to prevent rust and wear.

In addition to the excellent quality of the product itself, GFM is also known for its personalized customization service. Whether it is size, material or special process treatment, we can tailor it according to customer needs. Customers only need to provide the basic parameters and usage requirements of the equipment, and our technical team will give professional advice in the shortest time and design the most suitable solution.

Product Description

- Raw Material: 40CR

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Built for durability and precision, GFM bucket teeth pins ensure maximum efficiency for your heavy-duty tasks.

Features

- Durable Material: Premium alloy steel for extreme wear resistance.

- Perfect Fit: Precision-engineered to reduce wear and improve stability.

- Heat Treated: Enhanced hardness for longer service life.

- Rust-Resistant: Anti-corrosion coating for lasting performance.

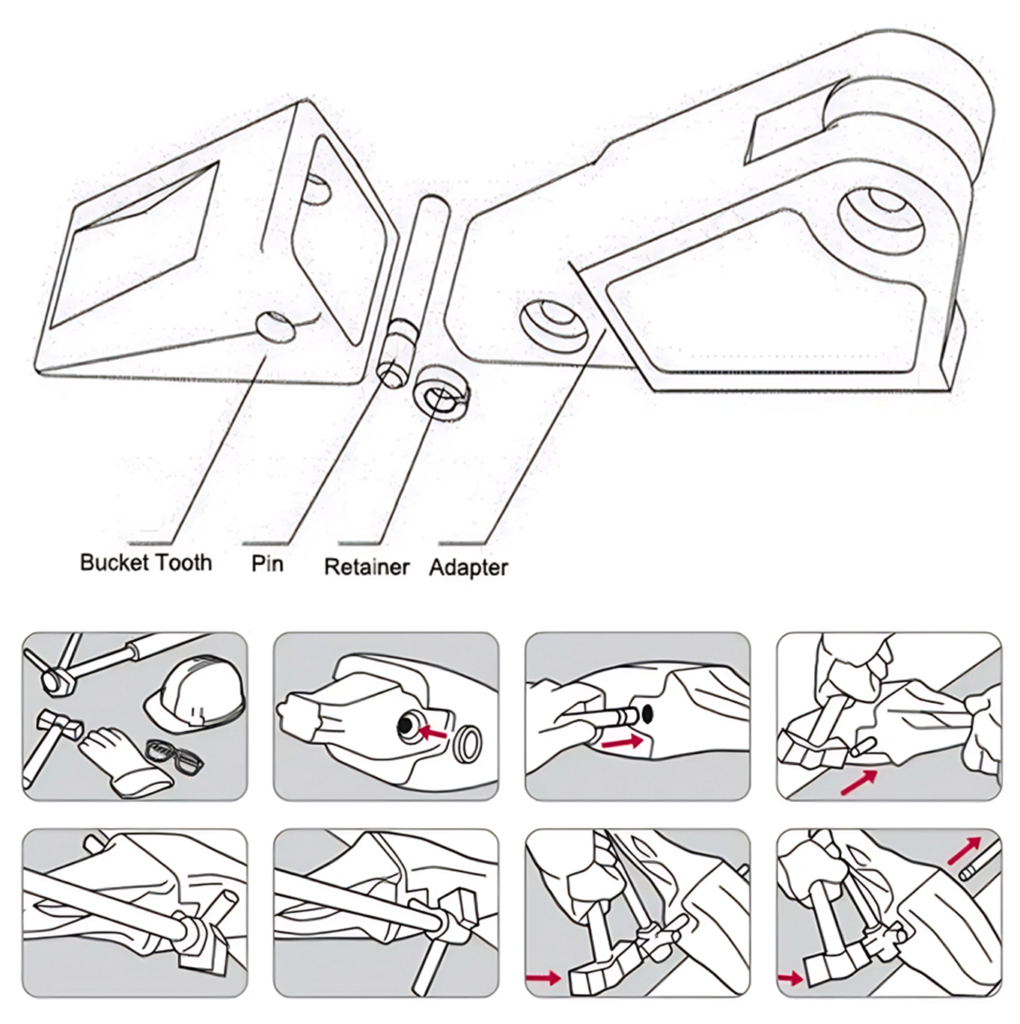

- Easy Installation: Quick and hassle-free replacement.

Choose GFM for reliable, cost-effective bucket teeth pins compatible with a wide range of excavators.

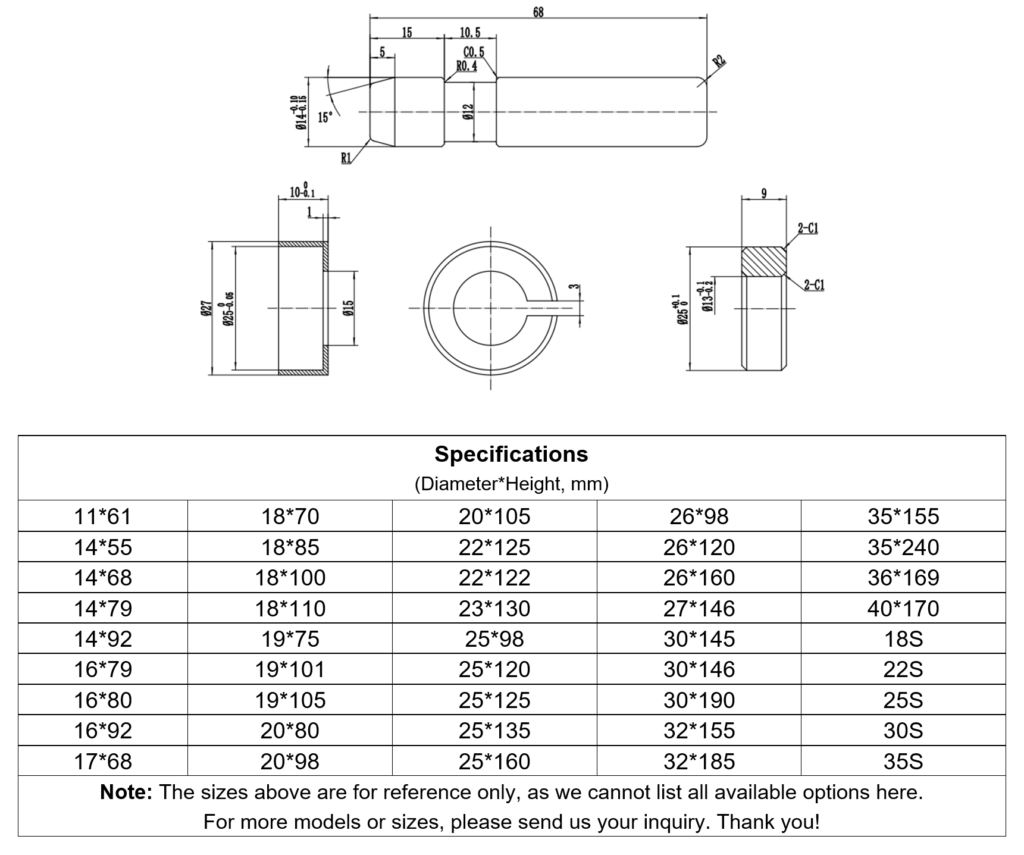

Specifications

Installation Steps

Product Models

Production Process

- Material selection: Only high-standard steel is used, and multiple tests are carried out to ensure quality.

- Processing technology: Precision processing using CNC machine tools to ensure dimensional accuracy.

- Surface treatment: Anti-rust and wear-resistant treatment to extend the service life.

- Inspection process: Each link passes strict quality inspection to ensure product stability.

The product design fully considers the mechanical wear and vibration issues, and the service life of the bucket tooth pin is extended through precise processing technology.

Packaging and Shipping

Factory Advantages

GFM factory has advanced CNC machine tools and testing equipment, and each production link is strictly implemented in accordance with international standards. We have introduced automated production lines and efficient testing systems, which not only improve production efficiency, but also ensure product consistency and stability.

The factory has a professional R&D team, who have profound attainments in mechanical design and material science, ensuring that every technical detail can reach the authoritative level in the industry. Through cooperation with many well-known companies, we have accumulated a large number of successful cases and actual data, proving that our bucket tooth pins are not only of excellent quality, but also can maintain high performance under different working conditions. For

GFM As a well-known accessories manufacturer in the industry, we not only focus on product research and development and technological innovation, but also attach more importance to customer experience and market feedback. GFM provides customers with high-quality and cost-effective product solutions with rich industry experience, professional technical team, strict quality management and flexible customized services. We encourage customers to interact and communicate with us to jointly explore the best application solutions to ensure that each product can give full play to its due value in actual work.

Whether you need a single trial or mass production, we can respond quickly and deliver accurately to help you gain an advantage in the fiercely competitive market. We hope that this product description can provide you with practical, specific suggestions and help for upgrading and repairing your equipment, and that we can work together to create brilliant achievements in the future.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW