Komatsu PC210 Track Idler Suppliers 2A5-30-00110

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

As a excavator idler manufacturer that has been focusing on manufacturing excavator undercarriage parts for many years, GFM is well aware of the technical points and working conditions of track idlers. For Komatsu PC210, we have adopted the following mature processes to ensure that each idler meets high quality standards:

- Selection of high-strength alloy steel: 40Mn alloy material is used in key parts to improve impact resistance and wear resistance.

- Integral forging + quenching and tempering heat treatment: The idler wheel body undergoes high-temperature forging and professional quenching and tempering heat treatment to ensure uniform internal stress distribution and not easy to crack.

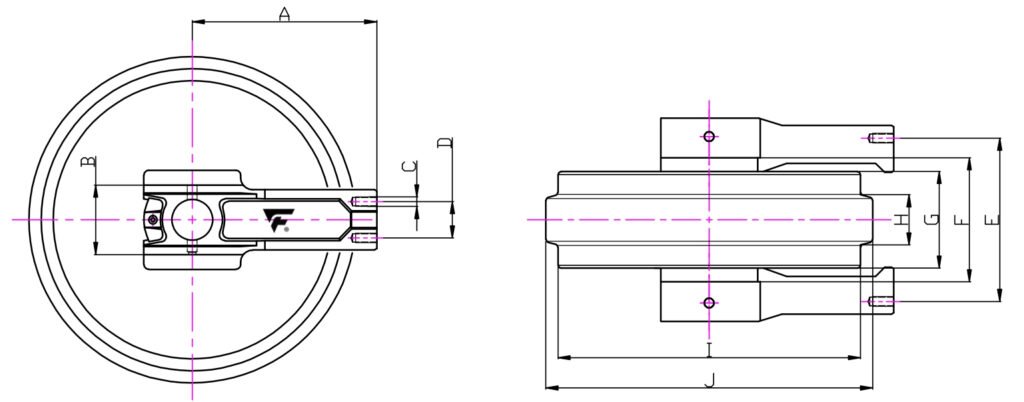

- Multi-pass CNC precision machining: Multiple precision machining is performed on key positions such as wheel rims and shaft holes, and the dimensional tolerance is strictly controlled, making the installation more matching.

- Double-layer sealing structure: Built-in high-quality floating oil seals and labyrinth structures effectively prevent mud and water from invading the bearing cavity.

- Shot peening + surface hardening treatment: The surface hardness of the wheel rim can reach HRC48 or above, significantly improving the overall service life.

According to field data feedback and customer verification, the average life of the PC210 idler produced by GFM can reach more than 1,800 hours, which is much higher than similar products in the general market.

Various specifications to meet different Komatsu models

Although we mainly promote the PC210 model, GFM also has track idlers for the following Komatsu models in stock for a long time:

- PC120 / PC130 / PC160

- PC200 / PC220 / PC240

- PC300 / PC360, etc.

Each model has detailed drawing dimensions and matching bolt hole specifications. If the customer requires a special structure (such as thickened rim, special tooth position, etc.), we support OEM/ODM non-standard customization services, from drawings to small batch samples.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM is not only a manufacturer, but also a one-stop solution provider for undercarriage parts. We have:

14 years of industry manufacturing experience: Deeply engaged in the field of engineering machinery parts, with cooperative customers in Southeast Asia, the Middle East, Latin America and other countries.

ISO9001 quality system certification: Every product leaving the factory must undergo strict quality inspection, including hardness testing, concentricity testing, high and low temperature simulation testing, etc.

Own casting + processing + assembly workshop: We control from the raw materials, minimize the intermediate links, and make the delivery time more flexible.

Annual production capacity exceeds 100,000 pieces: conventional models can be shipped quickly within 7 days, saving customers’ procurement time and cost.

Rich export experience: familiar with import and export customs clearance, wooden box packaging, sea freight FCL and bulk cargo LCL service processes.

Customized service to solve personalized needs

We understand that different countries and customers face different working environments. Some customers need to work in tropical humid environments, while others work under high-intensity impact in stone conditions. At this time, standard parts are often difficult to fully adapt. To this end, GFM launches the following customized service solutions:

✔ Provide thickened rims and anti-slip designs according to customer working conditions.

✔ Provide logo and customized color spraying services to enhance brand recognition.

✔ Customize non-standard shaft holes (such as tapered holes, spline holes, etc.).

✔ Can be purchased in packages with supporting parts such as tension springs and brackets.

✔ Provide one-to-one engineer drawing confirmation service to prevent mismatching.

You only need to provide: machine model, size drawings or old sample photos, and we can tailor your own excavator track idler solution for you.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

John Deere 330 Excavator Track Idler

- UNDERCARRIAGE

Liebherr R944 Excavator Track Idler Roller

- UNDERCARRIAGE

Sumitomo SH200 Excavator Track Idler Roller

- UNDERCARRIAGE

Excavator and Bulldozer Idler Wheel Manufacturers