Komatsu PC650-5 Excavator Track Idler Roller

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

The Komatsu PC650-5 is a heavy-duty hydraulic excavator that demands exceptional strength and precision from its undercarriage components. As one of China’s experienced excavator idler manufacturers, GFM specializes in producing high-performance and long-lasting excavator track idlers tailored specifically for the PC650-5, ensuring stable operation under all working conditions.

GFM’s PC650-5 idler is crafted from high-strength forged alloy steel, treated with advanced heat processing to enhance hardness and wear resistance. Designed to withstand shock and fatigue, it performs reliably in mining, roadwork, and other harsh environments.

Key product features:

- Precision fit: Perfectly compatible with Komatsu PC650-5 mounting dimensions, allowing for easy installation

- Exceptional durability: High-frequency quenched rims and precision bearings ensure long-term endurance

- Superior materials: Forged from high-purity alloy steel, offering uniform structure and excellent toughness

- Upgraded sealing system: Multi-layer seals effectively block contaminants like water, sand, and oil, protecting the internal bearing system.

Whether you need replacement parts or components for assembly, GFM remains your trusted partner among global excavator idler manufacturers.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

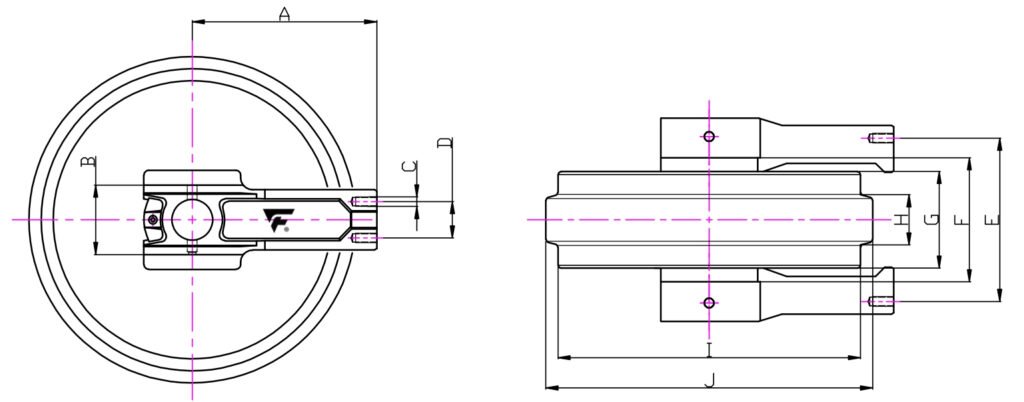

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

GFM operates a mature production line, sourcing premium raw materials to ensure durability even under the harshest conditions. We utilize advanced casting and forging processes, combined with comprehensive heat treatment, to deliver superior strength and toughness. Every part undergoes strict quality control to meet or exceed industry standards and customer expectations.

As a manufacturer with 14 years of experience, GFM has the capacity to fulfill both bulk and custom orders. Our professional production line ensures timely spare part supply to clients domestically and internationally. GFM has expanded from the domestic market to serve overseas customers, earning a solid reputation thanks to its industry knowledge, committed team, thoughtful service, fast delivery, and well-stocked inventory.

GFM is committed to maximizing customer value with superior aftermarket products. Whether you’re a long-term partner or a first-time customer, we look forward to working with you.

Key advantages:

- Product Guarantee: No less than 1-year or 2,000-hour quality warranty

- Strong Supply: Fast delivery, complete specifications

- Competitive Prices: 100% factory price, highly cost-effective

- Wide Compatibility: Fit for all mainstream brands

- Extensive Product Range: Track rollers, idlers, sprockets, chains, shoes, bolts, bushings, bucket pins, and more

- Lean Production: 5S & Kanban management for efficiency and consistency

- Collaborative Innovation: R&D with universities for material and sealing tech upgrades

- Closed-Loop QC: On-site feedback + testing + lab controls = consistent product excellence

- Responsive Delivery: Flat management enables rapid prototyping, sample approval, and mass production

If you have any personalized requirements or technical questions, feel free to reach out—we are here to help!

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Track Idler

Kubota Mini Excavator U15 Idler

- UNDERCARRIAGE

Kato HD700 Excavator Track Idler

- Track Idler

Liebherr R944 Excavator Track Idler Roller

- UNDERCARRIAGE

Sumitomo SH200 Excavator Track Idler Roller