Liebherr Bulldozer Crawler Tractor PR 726 Top Roller

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

The bulldozer carrier roller is a key component designed for crawler bulldozers. The Liebherr bulldozer or crawler tractor PR 726 top roller is made of high-quality alloy material and is precision machined to ensure wear resistance, high temperature resistance and corrosion resistance. The product surface is polished multiple times to effectively increase the life of the parts.

- High-strength material: advanced technology is used to ensure that the parts are not easily deformed.

- Precision machining: CNC equipment is used to ensure accurate dimensions.

- Multi-layer protection: surface treatment effectively prevents rust and wear.

Customization service

We know that each customer has different needs, so we provide personalized customization services. Whether it is size adjustment, material optimization, or special process requirements, we can respond quickly.

- Flexible customization: quickly adjust the design and process flow according to customer requirements.

- Dedicated service: professional customer service and technical team follow up throughout the process to ensure timely feedback.

- Quality assurance: customized products are also strictly tested to ensure that they meet the standards.

Through customized services, we not only provide high-quality products, but also help customers improve the overall equipment performance, truly realizing “one-to-one” intimate service.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Bulldozer or Crawler Tractor

- Packing: Standard Export Wooden Pallet

Features

- Long-Lasting Durability: Crafted from high-grade, wear-resistant steel for maximum strength and extended lifespan.

- Sealed and Lubricated: Fully sealed design keeps out dirt, water, and contaminants, minimizing wear and maintenance.

- Smooth Operation: Precision-engineered to provide efficient and stable support for the upper portion of the track.

- Corrosion Resistance: Corrosion-resistant surface treatments ensure reliable operation in harsh environments.

- Fits Various Models: Designed to fit a wide range of excavator and bulldozer models for various applications.

- Proven Toughness: Tested to perform reliably under extreme conditions, reducing downtime and increasing productivity.

At GFM Factory, our carrier rollers are built to optimize your machinery’s performance, ensuring smoother track operations and extended equipment life.

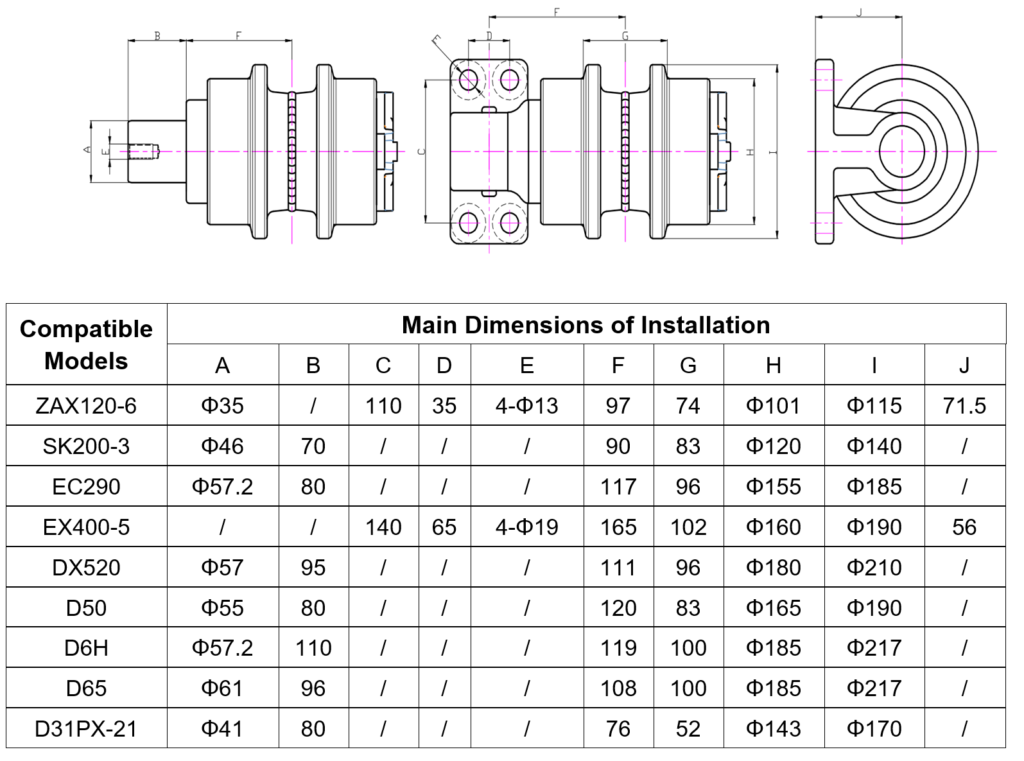

Product Models

Production Process

The production process is divided into four stages: raw material selection, CNC machining, surface treatment and final inspection. Each link is monitored by professionals to ensure that the process is smooth and without omissions.

- Raw material selection: Strictly select qualified suppliers to ensure that the materials are safe and environmentally friendly.

- CNC machining: High-precision equipment monitors dimensional errors in real time to ensure product consistency.

- Surface treatment: Use environmentally friendly technology to improve durability and appearance.

- Final inspection: Each product undergoes multiple tests before leaving the factory to ensure zero defects.

Through this rigorous process, we can provide customers with stable and reliable products, reflecting professional knowledge and technical strength.

Packaging and Shipping

Factory Advantages

GFM Excavator Parts Factory has more than 10 years of manufacturing experience, advanced equipment, and an experienced technical team. The factory not only has multiple high-precision CNC machine tools, but also has introduced international standard testing equipment.

Rich experience: Focusing on the production of mechanical parts for many years, we have accumulated rich practical experience.

Professional equipment: Use advanced equipment to ensure product stability.

Technical team: Professional technicians follow up the production process at any time to ensure quality.

The factory production process strictly follows the ISO quality management system to ensure that each batch of products has the highest level of quality assurance.

Practical suggestions and operating tips

For customers using PR 726 top rollers, the following suggestions can be used for reference:

- Regular inspection: It is recommended to inspect the roller surface and connection parts after each period of operation.

- Cleaning and maintenance: Regular cleaning to keep the surface clean and extend the service life.

- Professional installation: It is recommended to be installed by professionals to ensure assembly quality.

- Timely communication: If you have special needs or questions, please contact our technical support in time.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Excavator and Bulldozer Idler Wheel Manufacturers

- UNDERCARRIAGE

Excavator and Bulldozer Carrier Roller Manufacturers

- UNDERCARRIAGE

Bulldozer Swamp Track Shoe Supplier