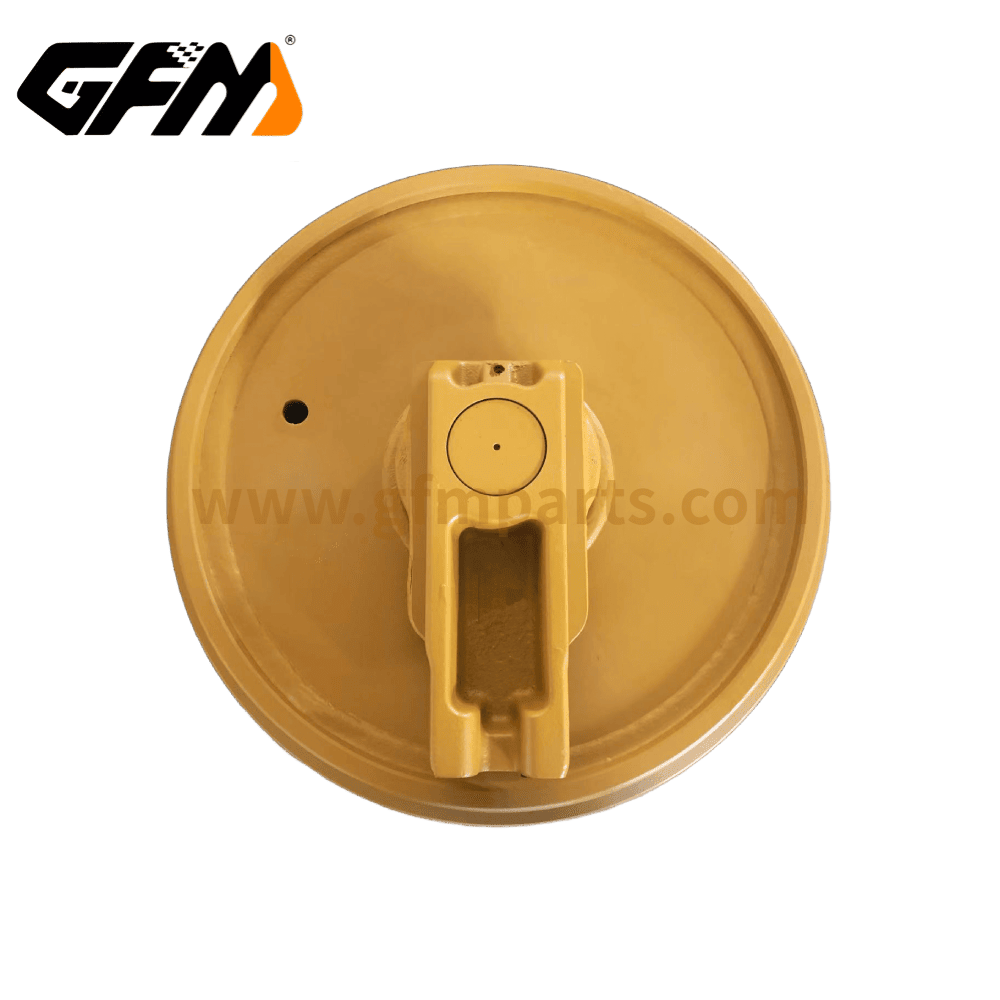

Liebherr R944 Excavator Track Idler Roller

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM has specially developed high-quality idlers for the Liebherr R944 excavator to improve work efficiency and service life. As an important component of the track travel system, the excavator track idler plays the dual role of guiding and tensioning the crawler, and is the key to keeping the equipment running smoothly. ,

Our idlers are tailor-made for the Liebherr R944, perfectly matching its chassis geometry and load requirements.

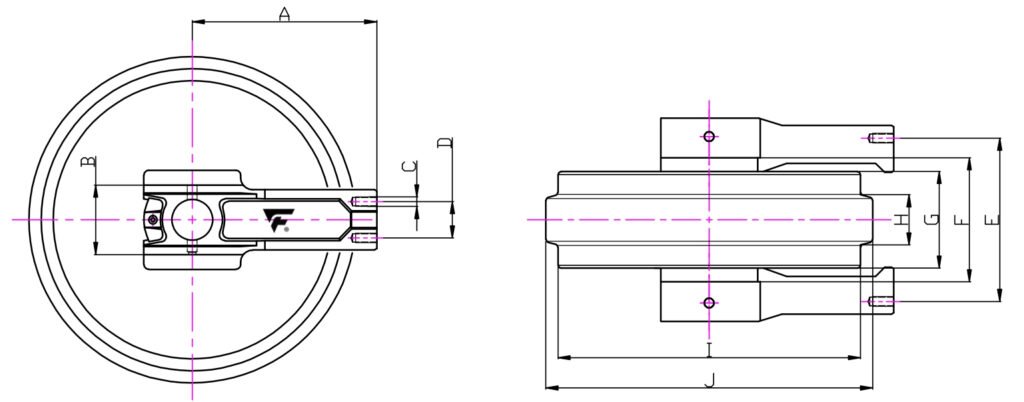

- Precise matching: diameter, width, bearing hole position, and bracket hole position are all manufactured according to the original R944 factory standards.

- High-strength alloy: heat-treated steel is selected for higher strength and less prone to deformation.

- High-quality bearings: Equipped with imported Swedish roller bearings, with strong load-bearing capacity and reliable dust-proof seals.

- Surface strengthening: The outer ring of the roller is nitrided or carburized, and the wear resistance and corrosion resistance are significantly improved.

- Vibration reduction design: The internal structure is optimized to effectively disperse the impact force and reduce the impact on the chassis and steering mechanism.

- Easy to maintain: Standard lubrication holes are reserved, and daily maintenance only requires simple grease filling to extend service life.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Specifications

Product Models

Production Process

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Raw material inspection

- Select high-quality alloys and high-strength materials, and undergo strict chemical composition analysis and mechanical property testing.

- Clear test data records ensure that the materials fully meet the standard requirements.

- CNC machining and molding

- Use high-precision CNC machine tools for precision machining to ensure the dimensional accuracy of parts.

- The molding process has been repeatedly optimized to make the product surface smooth and avoid wear problems caused by machining defects.

- Surface treatment and heat treatment

- According to different application environments, select suitable surface treatment methods, such as spraying, galvanizing, etc., to improve the corrosion resistance of the product.

- The heat treatment process improves the internal structure of the material, increasing its hardness and wear resistance.

- Strict inspection and testing

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

At the same time, through simulated on-site working condition testing, the idler wheel is ensured to perform well in actual use.

- Each process has a special inspection link to ensure that unqualified products never leave the factory.

Packaging and Shipping

Factory Advantages

GFM PARTS professional excavator idler manufacturer has many years of manufacturing experience and strong technical force, and all equipment has reached the international advanced level. The following is a brief introduction to our factory advantages:

- Advanced production equipment: The introduction of multiple internationally leading CNC machining centers and fully automatic testing equipment ensures that each product is precisely processed and tested.

- Quality management system: Strictly operate in accordance with the ISO quality system, and there are detailed records from raw material acceptance to finished product delivery to ensure that every link is traceable and product quality is based on evidence.

- Professional R&D team: After years of market precipitation and technical accumulation, we have an experienced and skilled R&D team. We can respond quickly to customer needs and continuously optimize product design and process flow.

- Strong customization capability: The factory can flexibly adjust the production line to undertake small and medium-sized batches and large-scale orders. Whether it is special materials, complex processes or unique designs, they can be customized according to needs.

Advantages of customized services

GFM understands the special needs under different working conditions and provides flexible and comprehensive customized solutions to help you achieve the best performance:

- Material selection: Conventional alloy steel, high-toughness alloy or high-temperature resistant steel can be provided according to the working conditions to meet extreme environments.

- Special coating: Optional spray anti-corrosion, anti-stick or high-temperature resistant coating, suitable for complex working conditions such as seaside, desert, high heat, etc.

- Structural optimization: Supports design improvements such as increasing tensioning stroke, widening bearing surface, and improving sealing structure to improve track tensioning and guiding performance.

- Packaging and logistics: Provide moisture-proof film, anti-seismic filling and customized wooden box packaging to ensure that parts are intact during long-distance transportation.

- Exclusive drawings and numbers: Mark according to customer work number or project number to facilitate subsequent spare parts management and batch order tracking.

Friendly suggestions and practical tips

As an excavator parts factory, we not only provide high-quality products, but also hope to share some tips on using and maintaining track idler roller with customers to help you manage equipment more easily.

- Regular inspection: It is recommended to check the idler for obvious signs of wear or damage before and after each operation to detect problems in time and extend the life of the product.

- Proper installation: During the installation process, strictly follow the installation manual to ensure that all joints are firm to avoid affecting the operation of the equipment.

- Maintenance notes: Clean and lubricate the idler regularly to reduce the impact of dust and impurities on the friction surface and keep it running smoothly.

- Professional training: We regularly hold technical exchanges and training activities, invite customers to participate, and jointly discuss equipment maintenance methods and process improvement suggestions.

These practical tips can not only help you reduce the risk of failure in actual operations, but also provide strong guarantees for the long-term maintenance of equipment.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Komatsu PC650-5 Excavator Track Idler Roller

- UNDERCARRIAGE

Hitachi ZAX870 Front Idler Excavator

- UNDERCARRIAGE

Sumitomo SH200 Excavator Track Idler Roller

- UNDERCARRIAGE

Komatsu Bulldozer D275 Bulldozer Idler Wheel