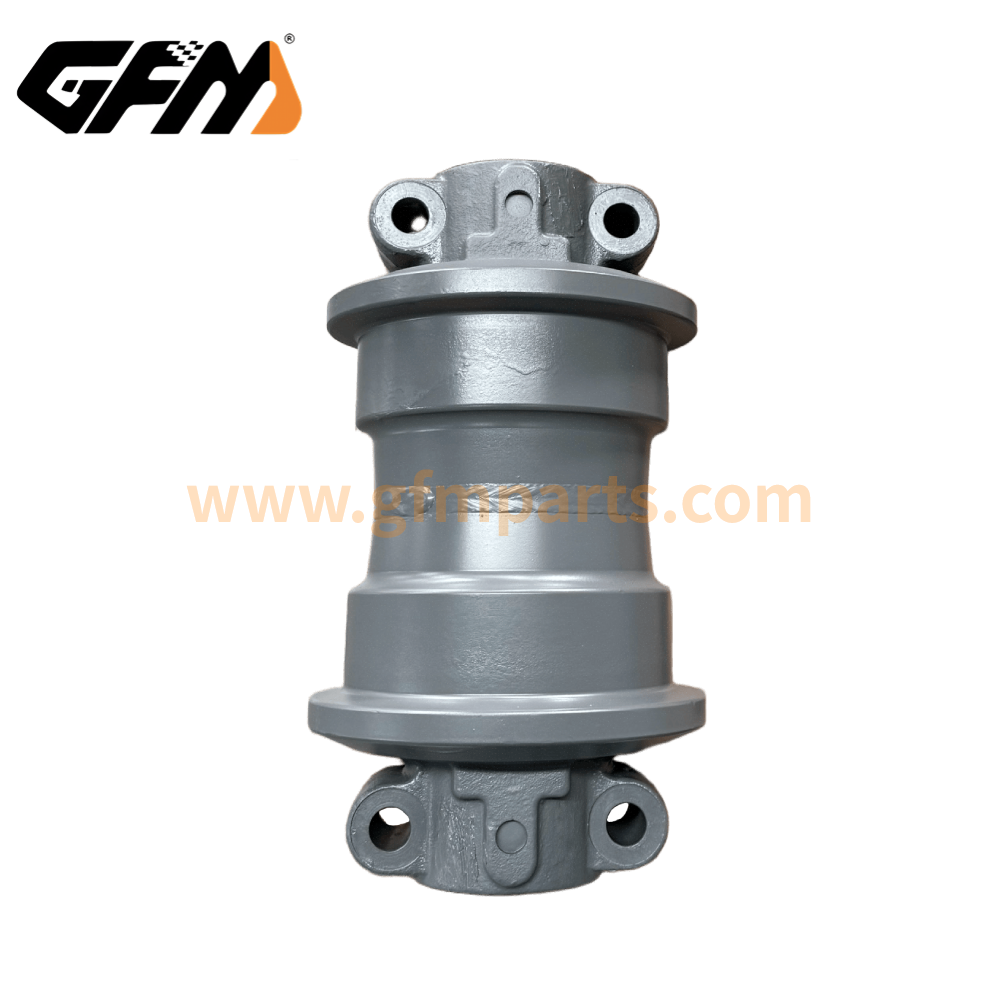

Liugong 936 Excavator Bottom Roller Factory

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

In the work of excavators, although the track roller is small in size, it is a key component in the chassis system. For medium-sized excavators such as Liugong 936, choosing a high-strength and durable track roller can not only improve the stability of operation, but also extend the life of the whole machine and reduce unnecessary maintenance costs.

As a GFM bottom roller factory focusing on the manufacture of engineering machinery undercarriage parts, we have tailored track rollers with high matching degree and exquisite craftsmanship for Liugong 936 excavators, and are committed to helping customers achieve long-term, stable and efficient equipment operation.

Accurately match the original machine parameters

The excavator bottom roller manufactured by GFM are strictly designed in accordance with the original drawing data of Liugong 936 to ensure seamless installation. The product adopts standard hole spacing, shaft diameter and installation method, and users can quickly replace the machine without additional debugging.

High-strength forged steel body, excellent load-bearing performance

The track roller body is made of high-strength alloy forged steel such as 40Mn2 and 50Mn, and is manufactured through rough processing, heat treatment, and fine processing. The surface hardness is high, the core maintains a certain toughness, and it takes into account the ability to resist pressure and impact. It is still stable even under heavy load and high-frequency vibration conditions.

Optimized lubrication and sealing structure, longer service life

GFM rollers adopt double-lip floating oil seal structure and inject high-viscosity grease to prevent dust, water vapor and other impurities from invading. Even in harsh environments such as mines, wetlands, and tunnels, it can still maintain stable internal lubrication and extend the service life by more than 30%.

Process details determine quality performance

- The wheel body has high processing accuracy and the deviation is controlled at ±0.05mm.

- The sleeve is made of wear-resistant alloy steel to improve the rotation flexibility.

- The welding parts are fully automatically welded by robots, and the welds are uniform, full and free of pores.

- The finished products are 100% airtight and load-bearing tested to ensure that there are no defects when leaving the factory.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- Premium Materials: Made with high-quality, wear-resistant steel to ensure a longer lifespan and consistent performance.

- Sealed and Lubricated: Designed with a sealed system that keeps the rollers lubricated, reduces friction, and prevents dirt or water from entering.

- Smooth and Stable Operation: Precision-engineered for balanced movement, improving the efficiency of your machinery.

- Fits Various Models: Offered in single-flange, double-flange, and center-flange designs to suit a wide range of excavators and bulldozers.

- Proven Toughness: Tested to handle heavy loads and operate effectively in rough environments, ensuring minimal downtime.

At GFM Factory, we are committed to delivering high-quality components that enhance the efficiency and longevity of your equipment. Our track rollers are designed to keep your machinery operating at peak performance, reducing downtime and maintenance costs.

For more information or to inquire about specific models, please contact us. GFM Factory – Your Reliable Parts Source!

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

14 years of chassis manufacturing experience

GFM has been deeply involved in the field of engineering machinery chassis parts since 2011, with multiple CNC processing lines, heat treatment lines and automatic welding production lines, with an annual output of more than 100,000 pieces. We are well aware of the specific needs of different equipment and working conditions, and can provide customers with two service modes: standard products and non-standard customization.

Strong R&D and customization capabilities to meet differentiated needs

In addition to Liugong 936, we also support the customization of multiple models of supporting rollers, including Komatsu, Hitachi, Caterpillar, Sanhe Intelligent, Xugong and other brands. Customers only need to provide equipment parameters or drawings, and we can design them exclusively for you, with controllable delivery cycles and support for small batch customization.

Support OEM/ODM and foreign trade exports

GFM has mature international cooperation experience and exports to more than 60 countries including Southeast Asia, the Middle East, South America, and Africa. Provide a full set of customized OEM services, including product design, packaging labels, packing materials, etc., to help overseas customers build brand competitiveness.

Worry-free after-sales and timely response

All products are provided with a 1-year warranty, and quality problems can be replaced free of charge. We have a professional after-sales team that responds to customer issues quickly within 24 hours to ensure that there are no blind spots in service.

Why choose GFM?

Choosing a track roller is not just choosing a component, but also choosing a guarantee for stable work. Every roller that GFM provides for Liugong 936 is the result of our 14 years of manufacturing experience and our persistent pursuit of quality. We always believe that:

- Quality comes from details, and service determines reputation.

- Customization makes the fit more accurate, and cooperation makes the efficiency more efficient.

If you are looking for a truly durable, highly matched, and reasonably priced roller product, GFM is your trusted partner.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Excavator and Bulldozer Idler Wheel Manufacturers

- Track Group

Bulldozer Track Group Manufacturer

- UNDERCARRIAGE

High Quality Bottom Roller Manufacturer

- UNDERCARRIAGE

High Quality Excavator Track Chain Manufacturers