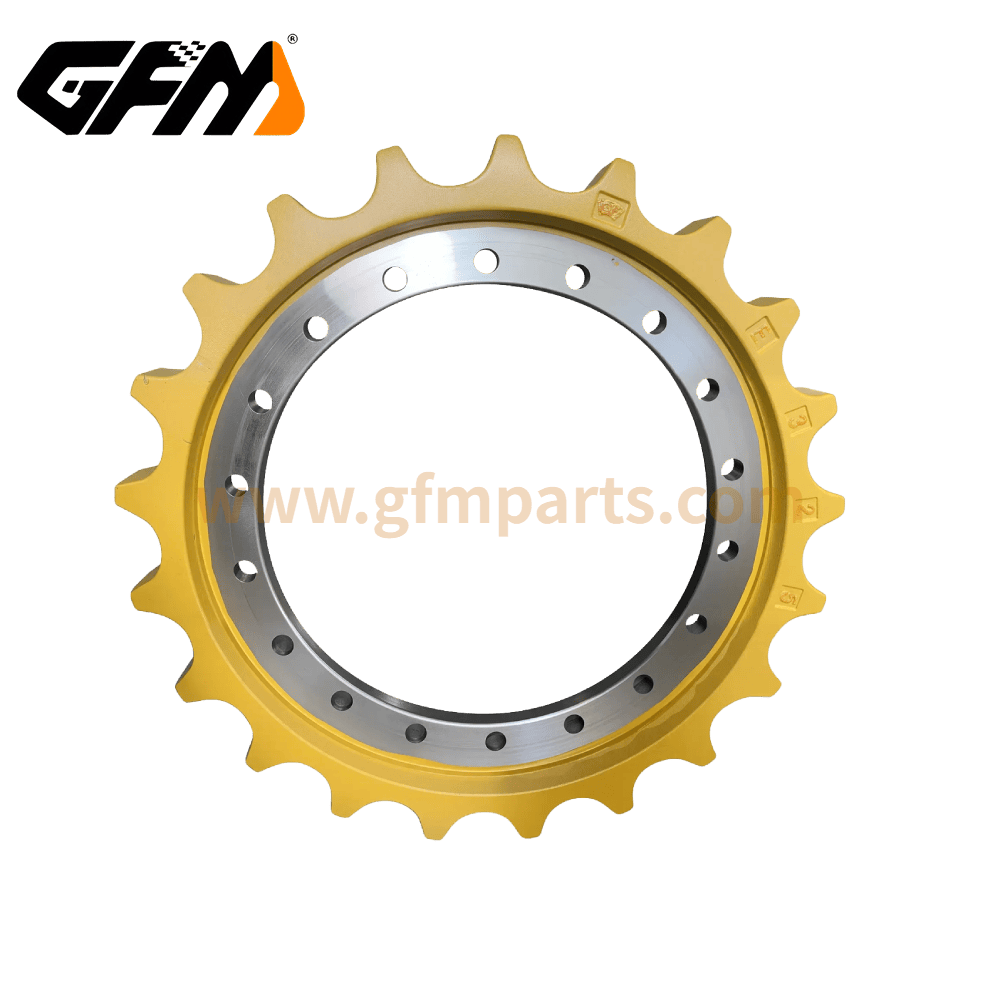

Wholesale CAT E325 Excavator Drive Sprocket 6Y4898

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

In the daily operation of the excavator, the sprocket is like the “backbone” of a machine, taking on the key tasks of transmitting power and driving the crawler. If you are looking for a durable, highly adaptable and stable performance excavator drive sprocket product for the Caterpillar CAT 325 excavator, GFM can give you a satisfactory answer.

GFM uses precise tooth design and heat treatment process for the sprocket of CAT 325 to ensure that it can perfectly mesh with the original chain, stably drive in various complex terrains, and reduce problems such as tooth skipping and breakage.

Not only that, we also provide a variety of materials and strengthening treatment options according to the working environment in different regions (such as rocks, gravel, humidity, low temperature, etc.), so that you can use it with peace of mind even under the most severe conditions.

High-strength alloy steel material, wear-resistant and impact-resistant

We select high-strength alloy steels such as 35MnB or 40Mn2, which have good ductility and high hardness. Through the overall forging molding process, not only the structural density is improved, but also the service life of the sprocket under heavy load and high-frequency operation is enhanced. After the surface is treated with medium frequency quenching, the hardness can reach HRC50-56, which significantly improves the wear resistance.

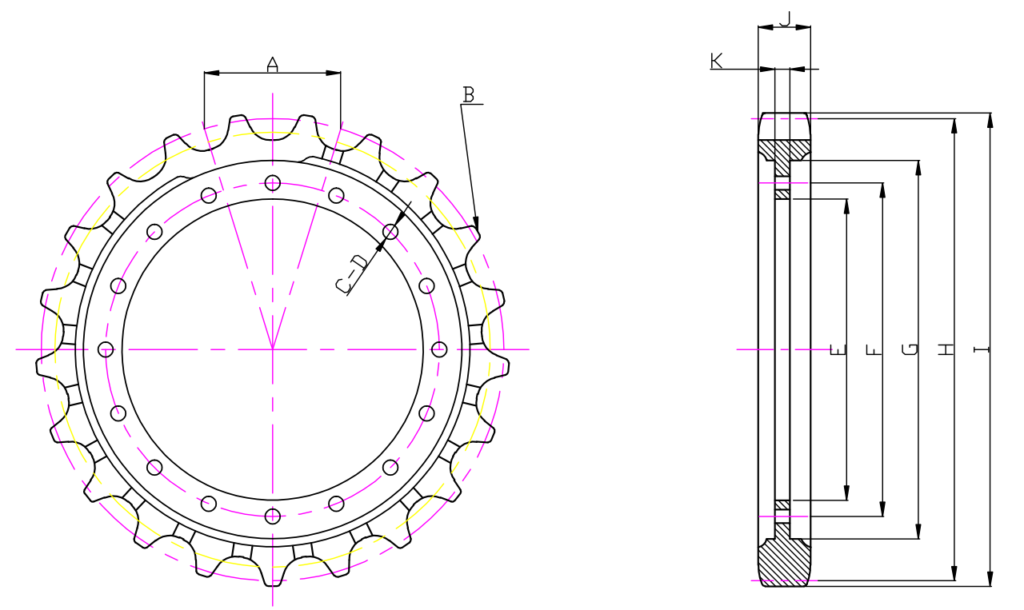

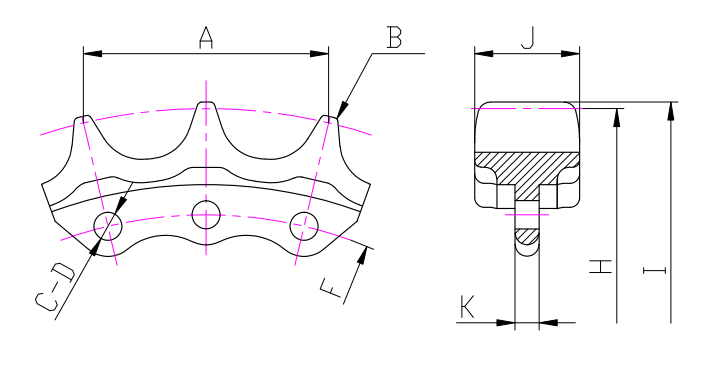

Precision machining to ensure smooth meshing

Each sprocket undergoes CNC precision machining and tooth pitch detection before leaving the factory to ensure high-precision meshing with the original crawler chain of CAT 325. Through gear hobbing and CNC turning, the meshing error between the sprocket and the crawler is minimized, wear and energy consumption are reduced, and the service life of the whole machine is extended.

Optional customization to meet the needs of different customers

We provide “customization on demand” services, including the number of sprocket teeth, hole position, tooth thickness, installation dimensions, etc., which can be processed according to the samples or drawings provided by the customer. Whether you are doing equipment renovation, after-sales service, or export wholesale business, GFM can provide you with highly consistent and highly matched sprocket matching solutions.

Product Description

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator or Bulldozer

- Packing: Standard Export Wooden Pallet

Features

- Exceptional Durability: Made from premium materials to endure heavy-duty operations and resist wear over time.

- Perfect Fit: Engineered for precise alignment with excavator and bulldozer track systems, ensuring optimal performance.

- High Load Capacity: Designed to withstand intense workloads while maintaining strength and stability.

- Effortless Operation: Ensures smooth engagement with the track chain, reducing vibration and boosting efficiency.

- All-Weather Performance: Built to resist rust, moisture, and extreme temperatures, ensuring reliability in any environment.

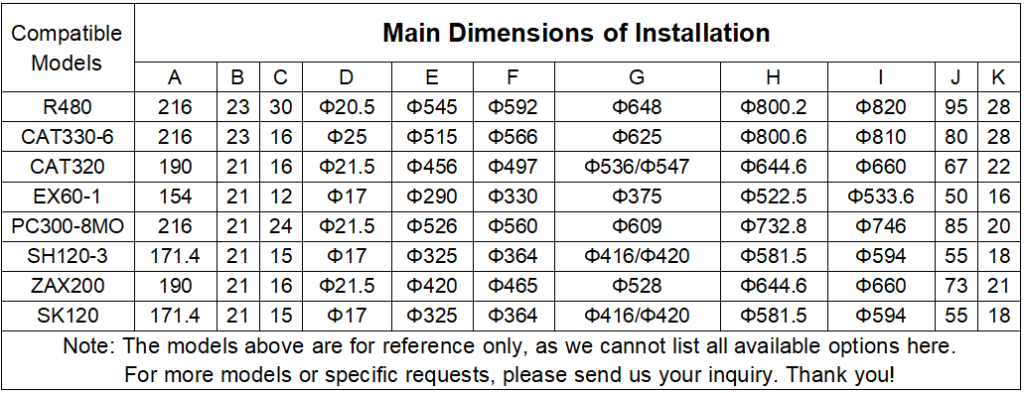

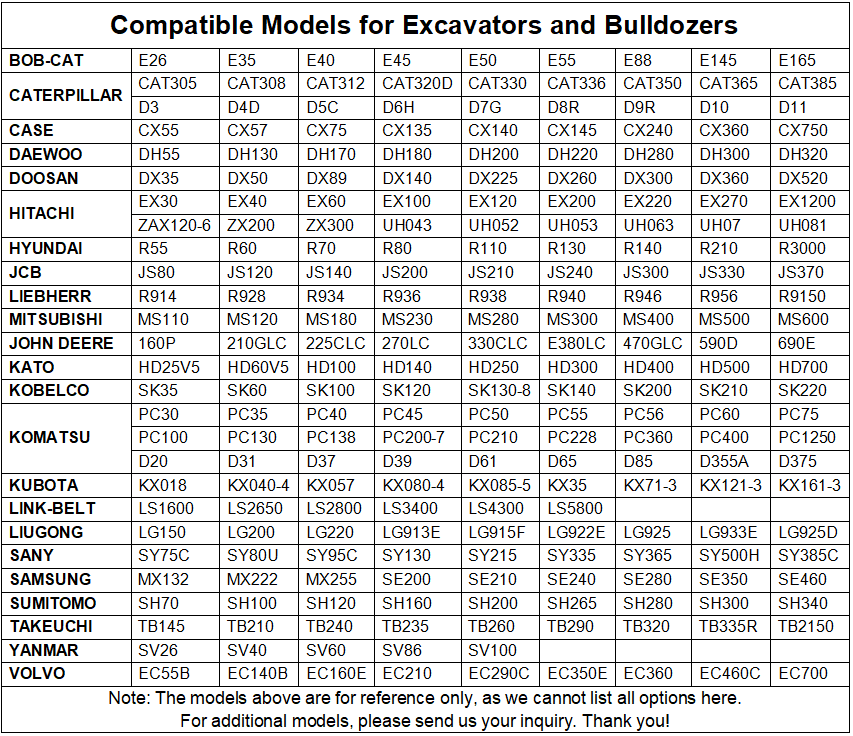

Specifications

Product Models

Production Process

- Forging blank: high-quality alloy steel bars are selected for isothermal forging to ensure that the internal structure is dense and uniform.

- Heat treatment: first quenching and then tempering, and then temperature tempering to eliminate internal stress; the balance of hardness and toughness makes the sprocket less likely to crack under high torque environment.

- CNC machining: precise cutting is carried out through the five-axis linkage CNC machining center, and each tooth surface is repeatedly polished to ensure the tolerance range and surface finish.

- Surface strengthening: high-temperature nitriding or phosphating treatment, combined with shot peening to eliminate residual stress and improve fatigue life.

- Quality inspection: equipped with advanced inspection equipment such as three-coordinate, hardness tester, profilometer, etc., full inspection of multiple indicators such as size, hardness, surface quality, magnetic particle flaw detection, etc.

- Dynamic balance test: The assembly test bench simulates the operation of the actual vehicle, detects vibration and temperature rise, and ensures that the products shipped meet the use requirements 100%.

Packaging and Shipping

Factory Advantages

GFM is an excavator sprocket manufacturer focusing on excavator chassis components. It has more than 10 years of production experience and an annual output of more than 50,000 sprockets of various types. Our sprocket products are not only popular in the Chinese market, but also exported to Europe, America, the Middle East, Southeast Asia and other countries.

The factory is equipped with a full-process production line including forging, heat treatment, CNC processing, CNC drilling, and automatic spraying to ensure that each product can achieve comprehensive quality control from raw materials to finished products.

Why choose GFM as a partner?

- Rich products: sprocket models cover mainstream brand excavators, such as Caterpillar, Hyundai, Komatsu, Doosan, Volvo, etc.

- Stable quality: Raw materials, processing accuracy and heat treatment process are fully controlled, and the rework rate is less than 0.3%.

- Flexible supply: Can accept small batch custom orders, and can also meet the stable batch supply needs of large dealers.

- Thoughtful service: technicians follow up one-on-one, support from design to delivery throughout the process, and solve your worries.

Although the sprocket is small, it plays a big role. Sprockets with poor adaptability or poor quality not only wear quickly, but also easily damage the track and drive motor. The Caterpillar CAT 325 sprocket provided by GFM provides stable driving force for your equipment with high-quality materials, precise manufacturing and considerate service.

If you are looking for a trustworthy and long-term sprocket manufacturer, please contact GFM – we are not only an accessory manufacturer, but also a good partner on your engineering journey.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Excavator and Bulldozer Sprocket and Segment

- UNDERCARRIAGE

High Quality Excavator Sprocket Supplier

- UNDERCARRIAGE

High Quality Excavator Track Idler Manufacturers