Wholesale Volvo EC460 Bucket Tooth Pin Lock 65P 14524710

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

As a crucial component of the Volvo EC460 excavator, the bucket tooth pin plays an indispensable role in construction operations. GFM has specialized in the research and manufacturing of excavator tooth pin for many years, understanding that the precision and durability of each pin are essential to construction efficiency and equipment lifespan.

Precise Fit: GFM’s Volvo EC460 Bucket Tooth Pin Lock is designed according to the specifications of the Volvo EC460 excavator, ensuring perfect alignment between the bucket tooth pin and the bucket lock holes. Whether working in high-strength soil or rocky conditions, each pin remains securely fixed, preventing loosening or falling off during operations.

High-Quality Materials and Wear Resistance: Our excavator tooth pin is made of high-strength alloy steel and undergoes a special heat treatment process, giving it uniform hardness and strong impact resistance. Multiple tests confirm that the pins maintain excellent wear resistance under heavy-duty operations, effectively extending service life and providing lasting protection for your machinery.

Advanced Manufacturing Process: GFM’s production process includes material selection, forging, heat treatment, precision machining, and strict quality inspection, ensuring each bucket tooth pin meets Volvo’s official standards. Through CNC precision machining, the pins achieve accurate dimensions and smooth surfaces, reducing wear and looseness during assembly and enhancing construction efficiency.

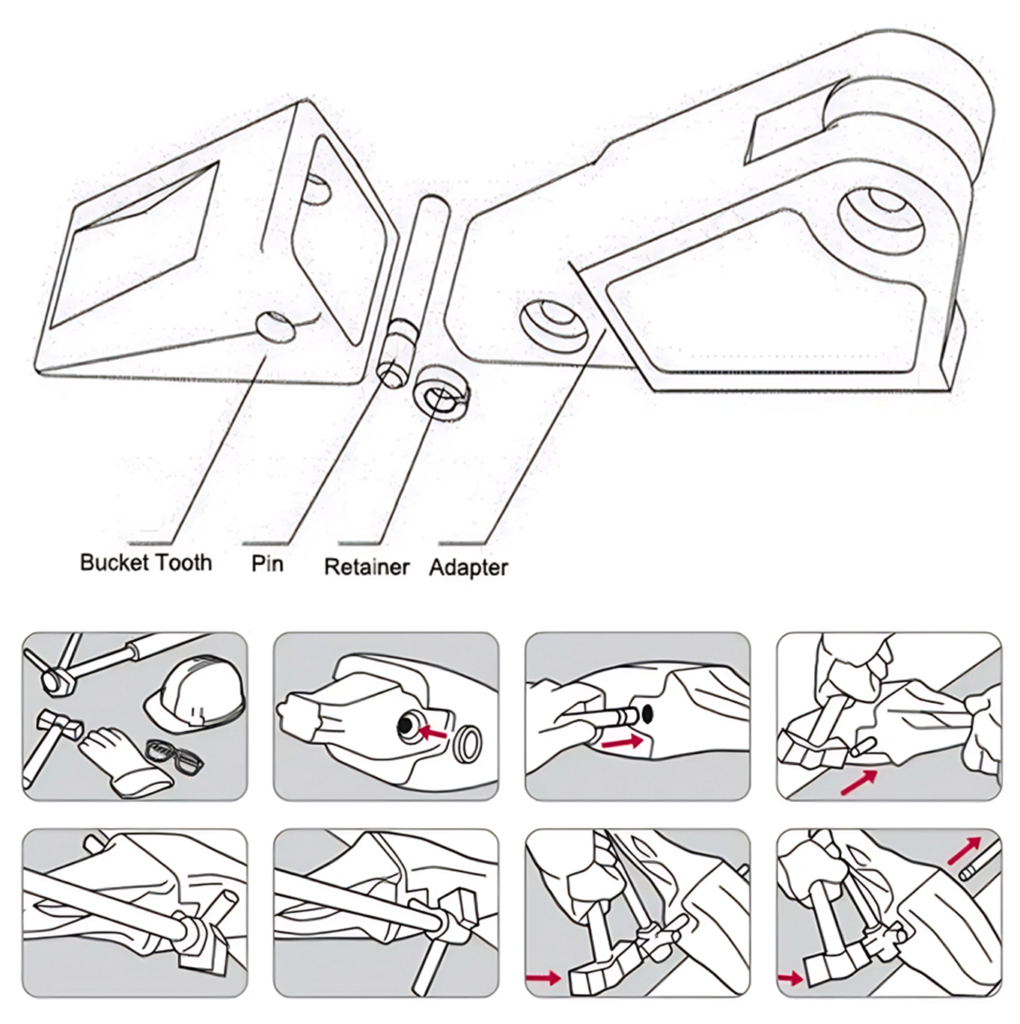

Easy Installation: The well-designed lock structure of the Volvo EC460 Bucket Tooth Pin Lock allows quick installation and removal. Even in limited field conditions, it can be replaced efficiently, reducing downtime and saving costs for construction projects.

Product Description

- Raw Material: 40CR

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Built for durability and precision, GFM bucket teeth pins ensure maximum efficiency for your heavy-duty tasks.

Features

- Durable Material: Premium alloy steel for extreme wear resistance.

- Perfect Fit: Precision-engineered to reduce wear and improve stability.

- Heat Treated: Enhanced hardness for longer service life.

- Rust-Resistant: Anti-corrosion coating for lasting performance.

- Easy Installation: Quick and hassle-free replacement.

Choose GFM for reliable, cost-effective bucket teeth pins compatible with a wide range of excavators.

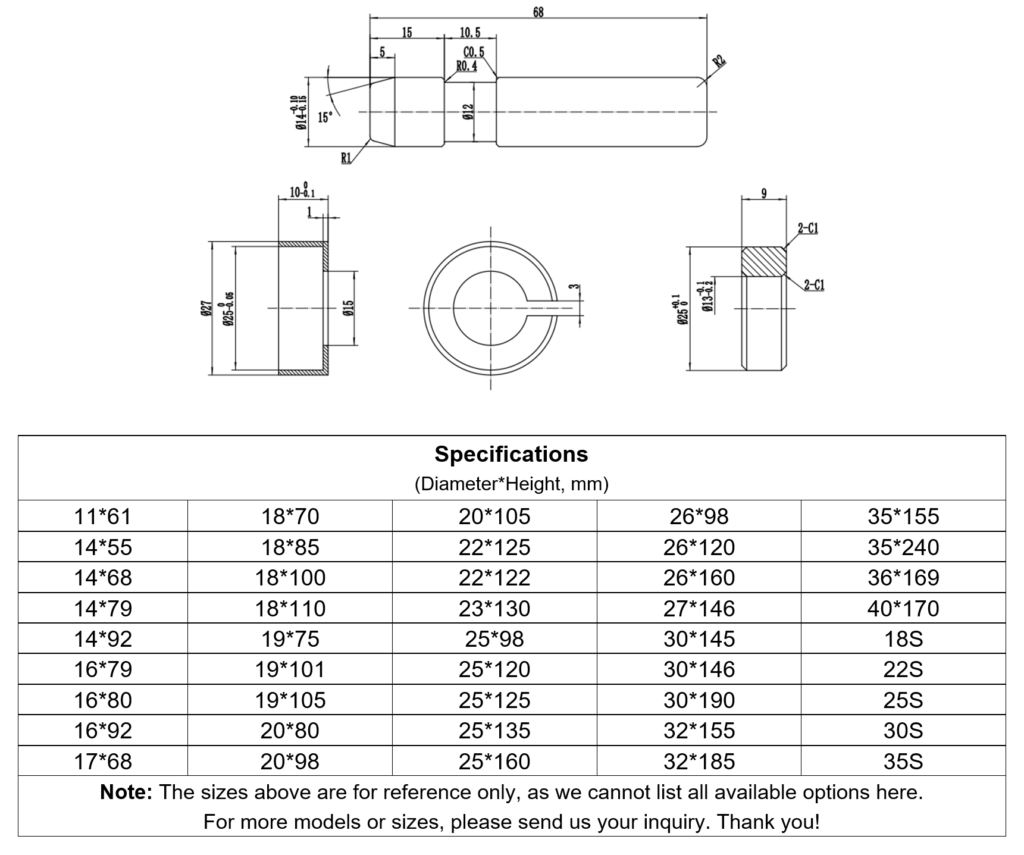

Specifications

Installation Steps

Product Models

Production Process

As a professional excavator parts manufacturer, GFM PARTS has first-class production facilities and an experienced team of engineers. With many years of manufacturing experience, it has become a recognized authoritative manufacturer in the industry. The factory introduces advanced processing equipment and strictly controls every link from raw material selection to finished product delivery. Specifically, our production process includes:

Material testing and selection: ensure that each batch of steel meets international standards

Precision machining: use CNC equipment to achieve high-precision machining

Surface treatment: use multiple processes for anti-corrosion and anti-wear processes

Final inspection: multiple quality inspection procedures to ensure product quality

Each process is operated by professional technicians to ensure high consistency and high reliability in the production process. We are well aware of the importance of product quality to engineering safety, so we strictly implement the ISO quality system and strive to provide customers with products and services that exceed expectations.

Packaging and Shipping

Factory Advantages

Choosing GFM means choosing professionalism and reliability, not just an excavator tooth pin.

Extensive Manufacturing Experience: GFM has focused on producing bucket tooth pin and lock components for years, with a complete R&D, production, and quality inspection system. With years of industry experience, we understand the performance requirements of pins in different working conditions and continuously optimize product design to meet clients’ needs for wear resistance, strength, and ease of installation.

Advanced Production Equipment: The factory is equipped with modern forging equipment, CNC precision machining centers, and automated heat treatment lines, ensuring dimensional accuracy and material consistency for every excavator tooth pin. The heat treatment and quenching process brings the hardness to HRC 45-55, balancing toughness and wear resistance.

Strict Quality Control: GFM has established a complete quality inspection system. From raw material intake to finished product delivery, each step is strictly monitored, including metallographic analysis, hardness testing, and wear experiments, ensuring every bucket tooth pin can withstand harsh real-world conditions.

Customer Trust and Service: Over the years, GFM products have been widely used in domestic and international excavator markets, serving industries such as construction, mining, and infrastructure. We provide not only high-quality products but also technical support and after-sales service, helping clients solve installation and usage issues. With professional guidance, the Volvo EC460 Bucket Tooth Pin Lock performs at its best.

Continuous Innovation and Optimization: GFM continually monitors market feedback and technological trends, improving material formulas, optimizing heat treatment parameters, and refining machining processes to enhance the overall performance of excavator tooth pin. Every innovation aims to make your machinery more reliable and construction more efficient.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- Bucket Tooth Pins

CAT E330 Bucket Tooth Pin and Retainer

- Bucket Tooth Pins

Komatsu PC100 Bucket Tooth Pin