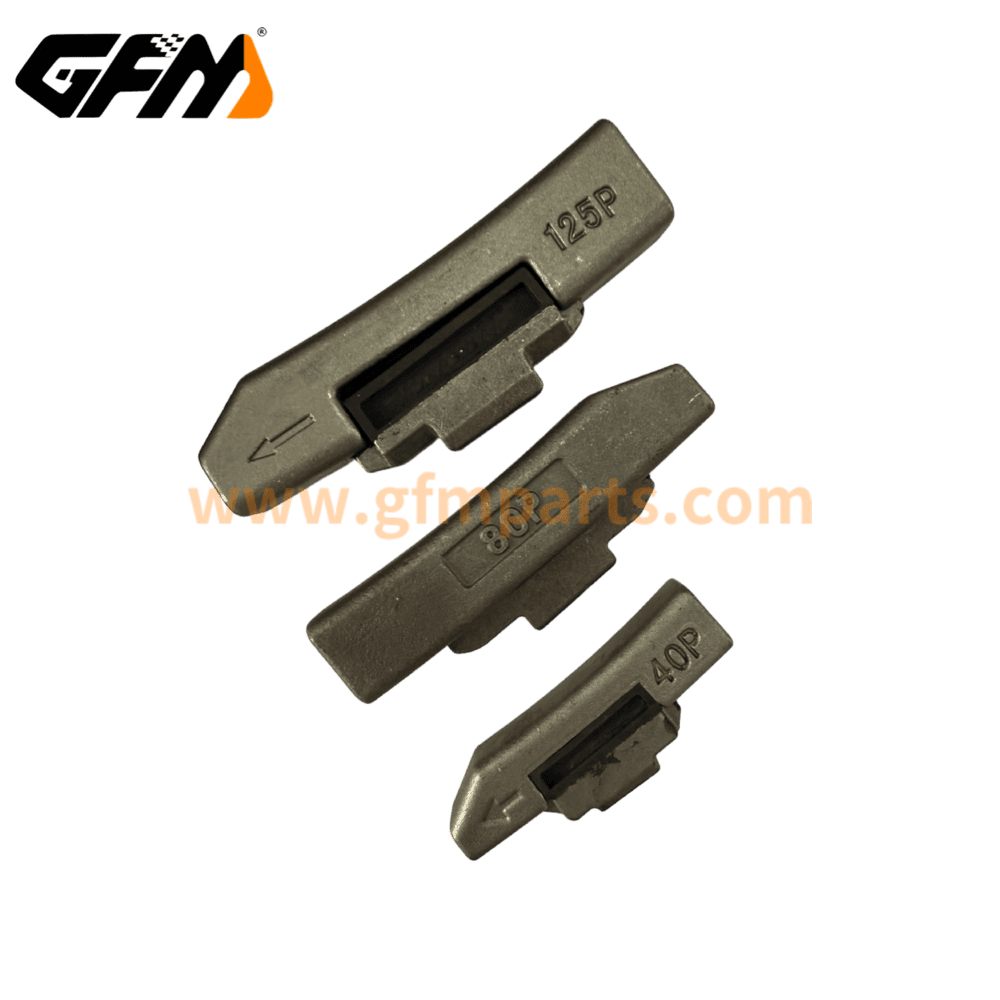

Wholesale Volvo Excavator Bucket Tooth Pin Lock 40P 80P 125P

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

Share

In the daily operation of excavators, the firmness and stability of bucket teeth are extremely important. If the bucket teeth become loose or fall off, it will not only affect construction efficiency but may also bring potential safety risks. Volvo Excavator Bucket Tooth Pin Lock 40P, 80P, 125P is the key component designed to solve this problem.

As the critical part connecting the bucket teeth and the adapter, the bucket tooth pin ensures that the teeth remain firmly in place during high-intensity operations. Whether in mining, infrastructure construction, or complex earthmoving projects, these excavator tooth pins guarantee that the teeth will not fall off easily, thus extending the service life of the excavator and improving overall efficiency.

According to different working conditions, the Volvo series commonly includes the following models:

- 40P: Suitable for small and medium excavators, lightweight and reliable for daily construction needs;

- 80P: Widely used in medium and large excavators, offering higher strength and reliability, ideal for earthmoving and material handling;

- 125P: Designed for large excavators, outstanding performance in mining, high-impact, and high-wear environments.

These excavator tooth pins feature easy installation, strong wear resistance, and long service life, making them indispensable parts in excavator operations.

Product Description

- Raw Material: 40CR

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Built for durability and precision, GFM bucket teeth pins ensure maximum efficiency for your heavy-duty tasks.

Features

- Durable Material: Premium alloy steel for extreme wear resistance.

- Perfect Fit: Precision-engineered to reduce wear and improve stability.

- Heat Treated: Enhanced hardness for longer service life.

- Rust-Resistant: Anti-corrosion coating for lasting performance.

- Easy Installation: Quick and hassle-free replacement.

Choose GFM for reliable, cost-effective bucket teeth pins compatible with a wide range of excavators.

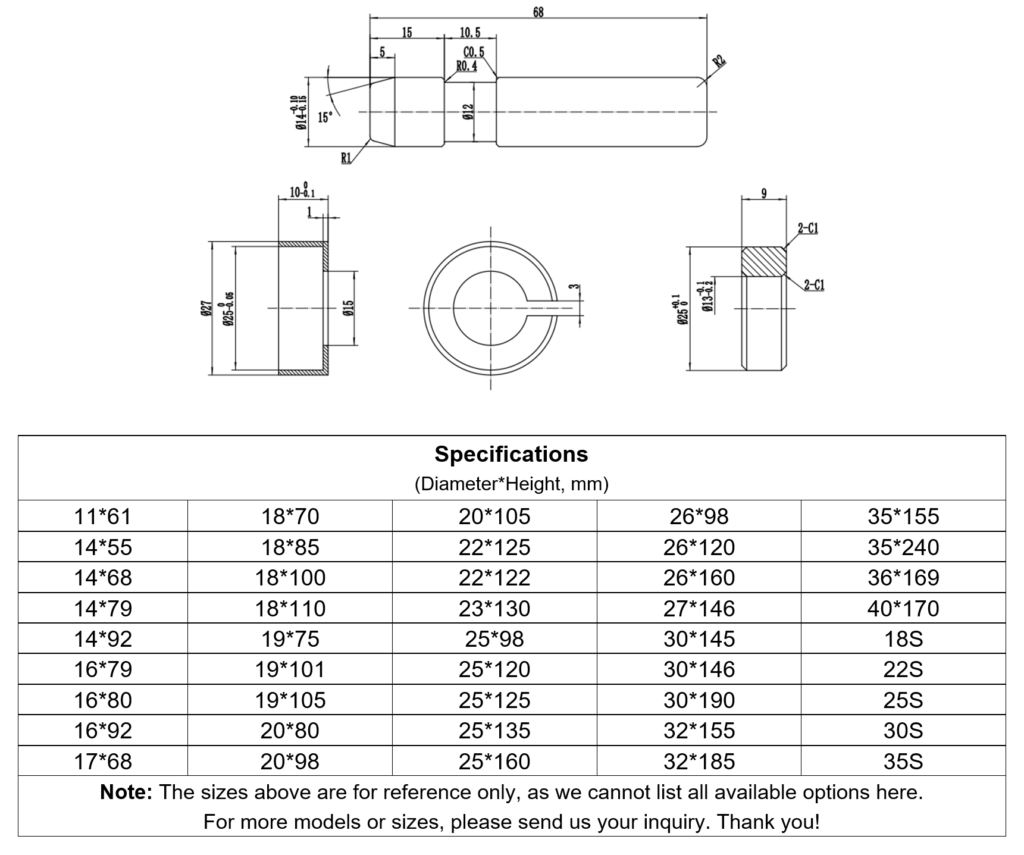

Specifications

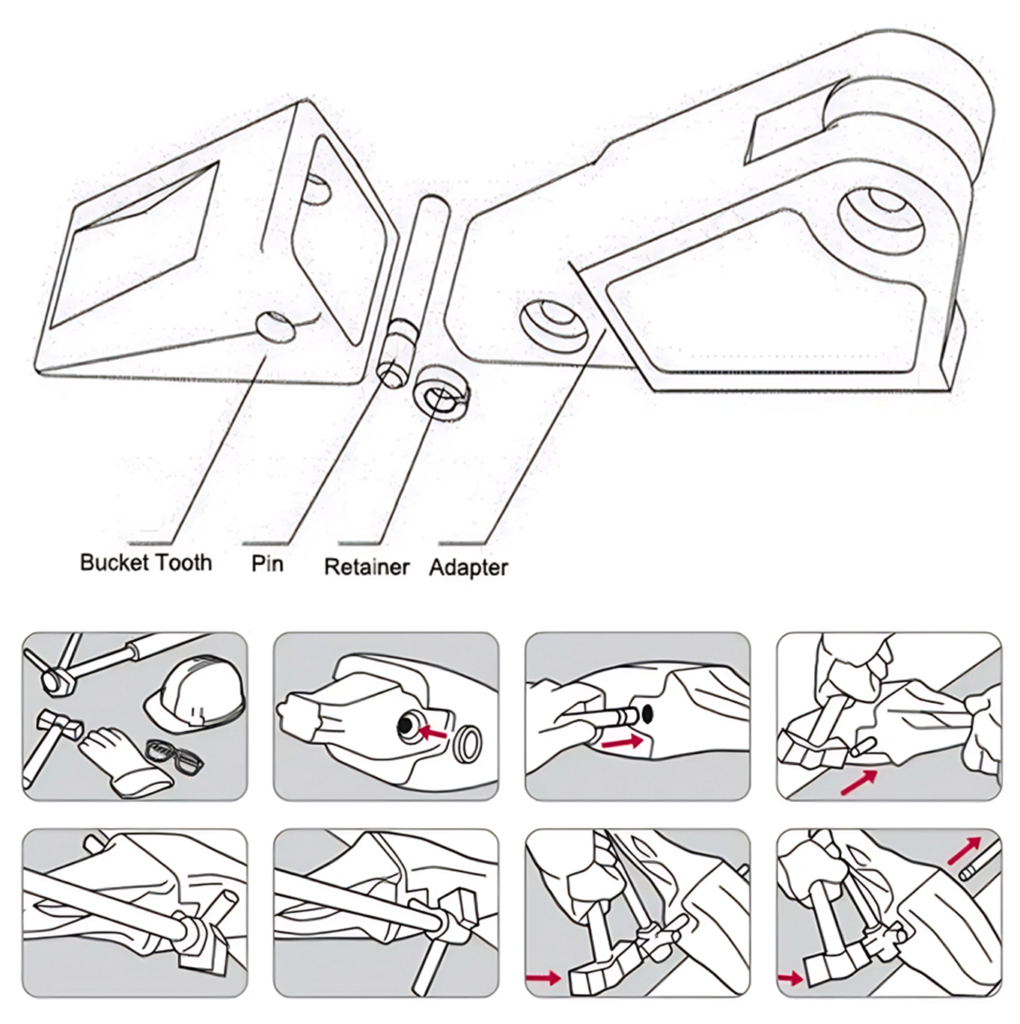

Installation Steps

Product Models

Production Process

As a professional excavator parts manufacturer, GFM PARTS has first-class production facilities and an experienced team of engineers. With many years of manufacturing experience, it has become a recognized authoritative manufacturer in the industry. The factory introduces advanced processing equipment and strictly controls every link from raw material selection to finished product delivery. Specifically, our production process includes:

Material testing and selection: ensure that each batch of steel meets international standards

Precision machining: use CNC equipment to achieve high-precision machining

Surface treatment: use multiple processes for anti-corrosion and anti-wear processes

Final inspection: multiple quality inspection procedures to ensure product quality

Each process is operated by professional technicians to ensure high consistency and high reliability in the production process. We are well aware of the importance of product quality to engineering safety, so we strictly implement the ISO quality system and strive to provide customers with products and services that exceed expectations.

Packaging and Shipping

Factory Advantages

Choosing a reliable manufacturer is crucial. GFM has accumulated long-term experience and industry-recognized strength in the production of excavator tooth pins, ensuring the quality and reliability of its products.

- 20 Years of Manufacturing Experience: GFM has specialized in excavator parts manufacturing for more than two decades. With a deep understanding of different industries’ needs for bucket tooth pins, the company consistently delivers reliable products to help customers face various challenges.

- Strict Quality Management: The factory has passed ISO9001 quality management system certification. From raw materials to finished products, strict quality control is implemented. Every single pin undergoes testing to ensure hardness, wear resistance, and safety meet international standards.

- Advanced Production Equipment: The factory is equipped with modern production machines and testing instruments to guarantee machining accuracy and consistency. This makes Volvo Excavator Bucket Tooth Pin Lock 40P 80P 125P more stable and reliable in actual use.

- Global Export Experience: GFM’s products are exported to more than 50 countries and regions, including Europe, Southeast Asia, the Middle East, and Africa. With stable quality and strong reputation, the company has established long-term partnerships with many overseas customers.

- Industry Reputation: Over the years, GFM has built an excellent reputation worldwide. Customers value not only the reliability of the products but also the long-term stability in service, delivery, and quality assurance.

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW