Rolo tensor para escavadeira Sumitomo SH210

- Qualidade garantida do produto

- Fornecimento grande

- Preços competitivos

- A maioria das marcas e modelos

- Equipe de Atendimento ao Cliente Útil

- Suporte técnico profissional

No setor de máquinas de construção, a escavadeira Sumitomo SH210 é muito apreciada pelos usuários por seu alto desempenho e durabilidade. A GFM PARTS fornece rolo tensor da escavadeira Projetado para este modelo, a fim de fornecer o melhor suporte operacional para o seu equipamento. Nossos produtos não são apenas rigorosamente inspecionados pelo processo, mas também contam com tecnologia avançada no processo de produção para garantir que cada produto tenha excelente durabilidade e estabilidade. Ao mesmo tempo, nossa fábrica possui vasta experiência em fabricação e sólida capacidade de P&D, podendo fornecer serviços personalizados de acordo com as necessidades do cliente, para que você possa sempre manter sua vantagem na competição acirrada.

- Design preciso: Nossas rodas-guia são personalizadas para escavadeiras Sumitomo SH210, e as peças são combinadas com precisão. A equipe de projeto realiza pesquisas aprofundadas sobre os cenários de uso do equipamento para garantir que as rodas-guia possam suportar condições extremas de trabalho e não reduzam o desempenho devido à operação a longo prazo.

- Artesanato requintado: Equipamentos avançados e um rigoroso fluxo de processo são utilizados no processo de produção, e cada etapa, desde a seleção da matéria-prima até o produto final, é cuidadosamente inspecionada. A retificação fina e a medição rigorosa garantem que cada elo atenda aos mais altos padrões, para que você possa usá-lo com confiança.

- Alta durabilidade: A seleção de materiais de alta qualidade, aliada à tecnologia de processamento de ponta, garante a firmeza e a resistência ao desgaste do produto. Seja em ambientes de trabalho de alta intensidade ou em trabalhos de longa duração, ele mantém o desempenho estável e prolonga a vida útil.

- Atendimento personalizado: Sabemos que as necessidades de cada cliente são diferentes. Além de fornecer modelos padrão, também podemos personalizar os produtos de acordo com as condições específicas do equipamento do cliente. Seja em tamanho, material ou tratamento de superfície, podemos atender às suas necessidades.

Descrição do produto

- Quantidade mínima: 1 PC

- Método de pagamento: T/T

- Marca: GFM

- Doença: Novo

- Cor: Amarelo, Preto ou Personalizado

- Tempo de espera: 30 dias

- Garantia: 1 ano

- Serviço: OEM ou ODM

- Local de origem: Fujian, China

- Aplicativo: Escavadora

- Embalagem: Palete de madeira padrão para exportação

Características

- Durável:Construído para suportar condições difíceis para um desempenho duradouro.

- Ajuste perfeito: Projetado para fácil instalação em vários modelos de escavadeiras e tratores.

- Serviço Pesado: Suporta cargas pesadas para uma operação suave e estável.

- Suave e silencioso: Minimiza a vibração para movimentos mais suaves e melhor tração em todos os terrenos.

- Baixa manutenção: Autolubrificante para menos manutenção e mais tempo de atividade.

- Resistente às intempéries: Apresenta bom desempenho em qualquer clima, sendo resistente à ferrugem e a temperaturas extremas.

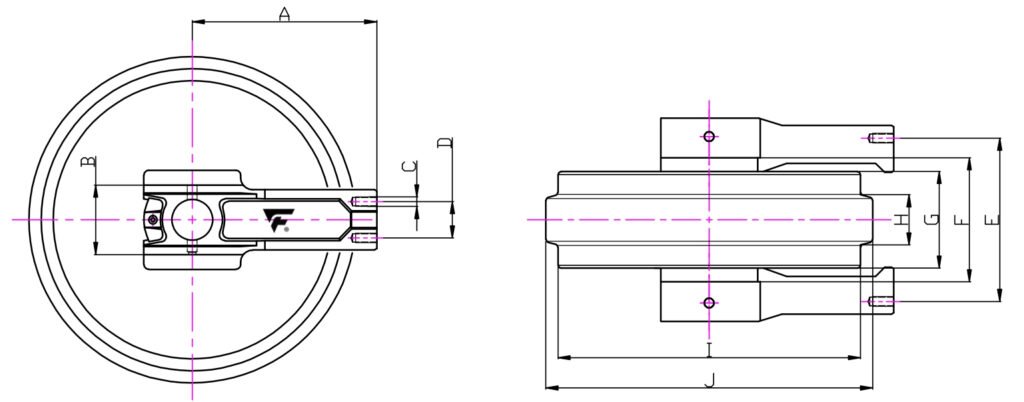

Especificações

Modelos de produtos

Processo de produção

Do projeto à entrega, cada etapa do processo dos nossos produtos é rigorosamente controlada para garantir a estabilidade e a durabilidade do produto. A seguir, uma introdução ao fluxo básico do processo:

- Inspeção de matéria-prima

- Selecione ligas de alta qualidade e materiais de alta resistência e passe por rigorosas análises de composição química e testes de propriedades mecânicas.

- Registros claros de dados de teste garantem que os materiais atendam totalmente aos requisitos padrão.

- Usinagem e moldagem CNC

- Utilize máquinas-ferramentas CNC de alta precisão para usinagem de precisão para garantir a exatidão dimensional das peças.

- O processo de moldagem foi repetidamente otimizado para tornar a superfície do produto lisa e evitar problemas de desgaste causados por defeitos de usinagem.

- Tratamento de superfície e tratamento térmico

- De acordo com diferentes ambientes de aplicação, selecione métodos adequados de tratamento de superfície, como pulverização, galvanização, etc., para melhorar a resistência à corrosão do produto.

- O processo de tratamento térmico melhora a estrutura interna do material, aumentando sua dureza e resistência ao desgaste.

- Inspeção e testes rigorosos

- Cada processo tem um link de inspeção especial para garantir que produtos não qualificados nunca saiam da fábrica.

Ao mesmo tempo, por meio de testes simulados de condições de trabalho no local, a roda intermediária tem garantia de bom desempenho em uso real.

- Cada processo tem um link de inspeção especial para garantir que produtos não qualificados nunca saiam da fábrica.

Embalagem e Envio

Vantagens da fábrica

GFM PARTS profissional fabricante de polias intermediárias para escavadeiras Contamos com muitos anos de experiência em fabricação e sólida força técnica, e todos os equipamentos atingiram o nível avançado internacional. A seguir, uma breve introdução às vantagens da nossa fábrica:

- Equipamentos de produção avançados: A introdução de vários centros de usinagem CNC líderes internacionais e equipamentos de teste totalmente automáticos garantem que cada produto seja processado e testado com precisão.

- Sistema de gestão de qualidade: operar rigorosamente de acordo com o sistema de qualidade ISO, e há registros detalhados desde a aceitação da matéria-prima até a entrega do produto acabado para garantir que cada elo seja rastreável e que a qualidade do produto seja baseada em evidências.

- Equipe profissional de P&D: Após anos de aceleração do mercado e acúmulo técnico, contamos com uma equipe de P&D experiente e qualificada. Podemos responder rapidamente às necessidades dos clientes e otimizar continuamente o design do produto e o fluxo do processo.

- Forte capacidade de personalização: A fábrica pode ajustar a linha de produção com flexibilidade para atender lotes de pequeno e médio porte e pedidos de grande escala. Sejam materiais especiais, processos complexos ou designs exclusivos, eles podem ser personalizados de acordo com as necessidades.

Vantagens dos serviços personalizados

Sempre seguimos o princípio de "cliente em primeiro lugar" e oferecemos soluções de personalização diversificadas para ajudar cada cliente a atender às suas necessidades. Os serviços personalizados que oferecemos incluem principalmente:

- Personalização dos parâmetros do produto: por meio da comunicação com os clientes, determine os parâmetros específicos mais adequados para o equipamento para garantir a correspondência perfeita dos requisitos do equipamento.

- Otimização do design: De acordo com o uso no local, nossos especialistas em design fornecerão sugestões de melhorias personalizadas para otimizar ainda mais o desempenho do produto.

- Resposta rápida: Seja uma modificação de desenho ou desenvolvimento de um novo produto, podemos responder às necessidades do cliente no menor tempo possível para garantir o andamento do projeto.

- Suporte de serviço completo: desde a consultoria pré-venda até a instalação e comissionamento pós-venda, oferecemos suporte técnico completo para garantir que os clientes não tenham preocupações durante o uso.

Este serviço personalizado não só melhora a praticidade do produto, mas também aumenta muito a confiança e a satisfação dos clientes conosco, além de estabelecer um relacionamento cooperativo estável e de longo prazo.

Sugestões amigáveis e dicas práticas

Como um fábrica de peças para escavadeiras, não apenas fornecemos produtos de alta qualidade, mas também esperamos compartilhar algumas dicas sobre o uso e a manutenção de polias com os clientes para ajudar você a gerenciar o equipamento com mais facilidade.

- Inspeção regular: Recomenda-se verificar se há sinais óbvios de desgaste ou danos na polia intermediária antes e depois de cada operação para detectar problemas a tempo e prolongar a vida útil do produto.

- Instalação correta: Durante o processo de instalação, siga rigorosamente o manual de instalação para garantir que todas as juntas estejam firmes para evitar afetar o funcionamento do equipamento.

- Notas de manutenção: Limpe e lubrifique a polia intermediária regularmente para reduzir o impacto de poeira e impurezas na superfície de atrito e mantê-la funcionando sem problemas.

- Treinamento profissional: realizamos regularmente intercâmbios técnicos e atividades de treinamento, convidamos clientes a participar e discutimos em conjunto métodos de manutenção de equipamentos e sugestões de melhoria de processos.

Essas dicas práticas não só podem ajudar você a reduzir o risco de falhas nas operações reais, mas também fornecer garantias sólidas para a manutenção de longo prazo do equipamento.

SOLICITE UM ORÇAMENTO AGORA

Fundada em 2011, a Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd. é uma fabricante experiente especializada em peças de reposição para escavadeiras e tratores de esteira, como peças para material rodante (rolos de esteira, rolos superiores, rodas-guia, rodas dentadas, sapatas de esteira, correntes de esteira, grupos de esteira), parafusos, porcas, pinos, buchas e muito mais. Cobrimos e mantemos em estoque uma ampla gama de peças aplicáveis à maioria das marcas e modelos disponíveis no mercado. As marcas compatíveis incluem Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abrangendo as principais marcas do mercado.

Perguntas frequentes

Somos um fabricante experiente. Nossa fábrica está localizada em Xiamei Town, Quanzhou. Sua visita é muito bem-vinda.

Forneça-nos o modelo correto da máquina, o número da peça ou algumas especificações. Caso não sejam itens padrão, envie os desenhos.

Geralmente aceitamos T/T; outros termos podem ser negociados.

Claro que sim. Oferecemos serviço OEM. Se você tiver amostras ou desenhos, juntamente com uma solicitação de grande quantidade, podemos personalizar os produtos e oferecer suporte técnico profissional.

A GFM estabeleceu um sistema completo de controle de qualidade, meio ambiente e segurança. Todas as peças passam por rigorosos testes e medidas de controle de qualidade antes da distribuição. Nossa fábrica segue rigorosos padrões de segurança e regulamentações ambientais nos processos de fabricação.

SOLICITE UM ORÇAMENTO AGORA

Produtos relacionados

- TREM RODANTE

Polia intermediária para escavadeira CAT 305