Fornecedor de rodas dentadas para escavadeira XCMG XE370

- Qualidade garantida do produto

- Fornecimento grande

- Preços competitivos

- A maioria das marcas e modelos

- Equipe de Atendimento ao Cliente Útil

- Suporte técnico profissional

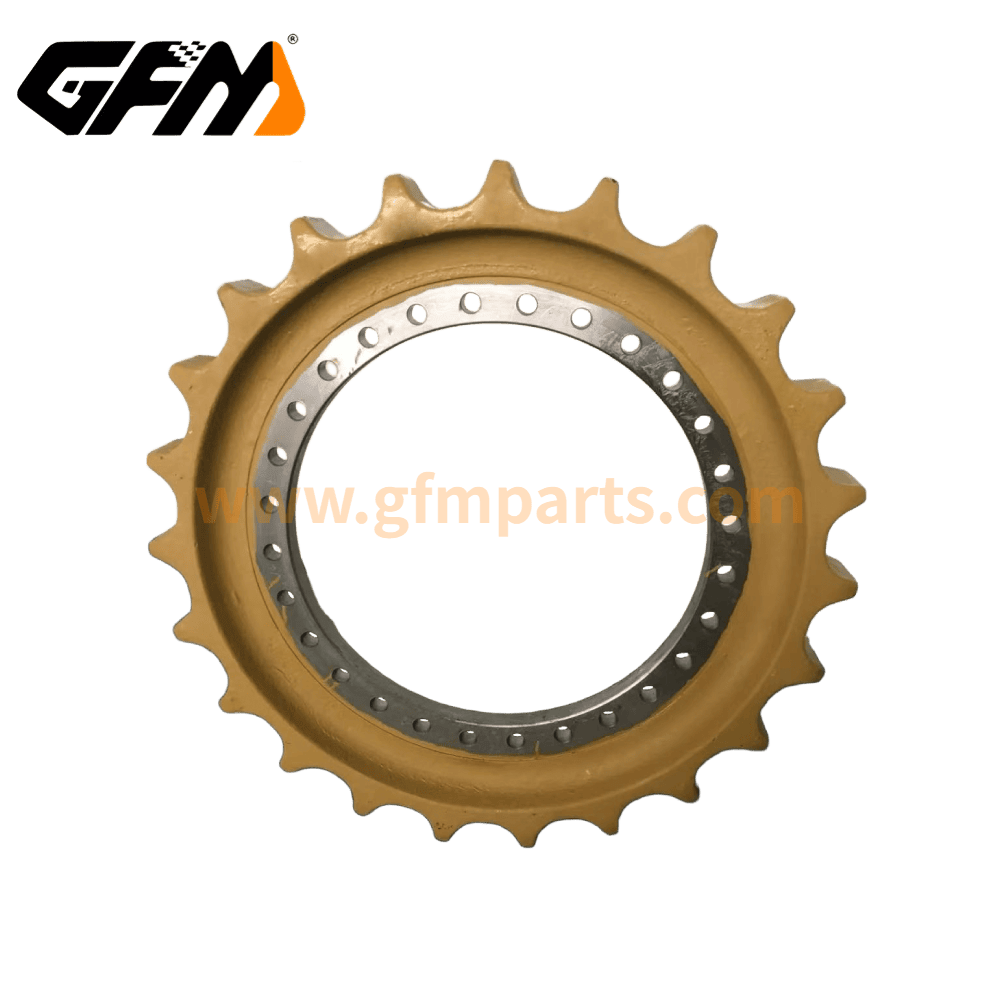

Na construção diária de escavadeiras pesadas como a XCMG XE370, a roda dentada, como parte importante de todo o sistema de acionamento da máquina, desempenha um papel fundamental na conexão da corrente e do sistema de transmissão, guiando a esteira para a frente. Se você procura uma roda dentada confiável, durável, fácil de instalar e personalizável, o produto da GFM será sua escolha confiável.

Esta roda dentada produzida pela GFM é feita sob medida para a escavadeira XCMG XE370, combinando resistência estrutural, resistência ao desgaste e facilidade de instalação. É forjada com precisão em aço-liga de alta resistência e possui alta dureza após têmpera e revenimento, o que pode efetivamente aumentar a vida útil e a resistência ao impacto. Os dentes da corrente são tratados com têmpera de média frequência para aumentar a resistência ao desgaste e podem manter a produção estável mesmo em condições de trabalho adversas, como cascalho, lama e superfícies escorregadias.

Como um fornecedor de rodas dentadas para escavadeira Com mais de 10 anos de experiência na fabricação de peças para máquinas de engenharia pesada, a GFM implementa processos padronizados em todas as etapas, desde a aquisição da matéria-prima até a inspeção de qualidade final. Nosso processo de produção de rodas dentadas inclui principalmente:

- Forjamento de precisão: O processo de forjamento em matriz fechada é usado para tornar o corpo da roda dentada mais denso e mais resistente a rachaduras.

- Usinagem CNC: o processamento da posição do furo e do formato do dente é concluído por equipamentos CNC de alta precisão, e o erro é controlado dentro de ±0,02 mm.

- Controle do tratamento térmico: A profundidade de endurecimento da superfície da roda dentada é controlada em 6-8 mm, o que não só garante a dureza da superfície, mas também retém a tenacidade do núcleo interno.

- Inspeção de qualidade: Cada lote de produtos deve passar por testes de dureza, análise metalográfica e testes de montagem antes de sair da fábrica para garantir que cada peça atenda a altos padrões.

Descrição do produto

- Quantidade mínima: 1 PC

- Método de pagamento: T/T

- Marca: GFM

- Doença: Novo

- Cor: Amarelo, Preto ou Personalizado

- Tempo de espera: 30 dias

- Garantia: 1 ano

- Serviço: OEM ou ODM

- Local de origem: Fujian, China

- Aplicativo: Escavadeira ou trator de esteira

- Embalagem: Palete de madeira padrão para exportação

Características

- Durabilidade Excepcional: Feito de materiais premium para suportar operações pesadas e resistir ao desgaste ao longo do tempo.

- Ajuste perfeito: Projetado para alinhamento preciso com sistemas de esteiras de escavadeiras e tratores, garantindo desempenho ideal.

- Alta capacidade de carga: Projetado para suportar cargas de trabalho intensas, mantendo a resistência e a estabilidade.

- Operação sem esforço: Garante um engate suave com a corrente da esteira, reduzindo a vibração e aumentando a eficiência.

- Desempenho em todas as condições climáticas: Construído para resistir à ferrugem, umidade e temperaturas extremas, garantindo confiabilidade em qualquer ambiente.

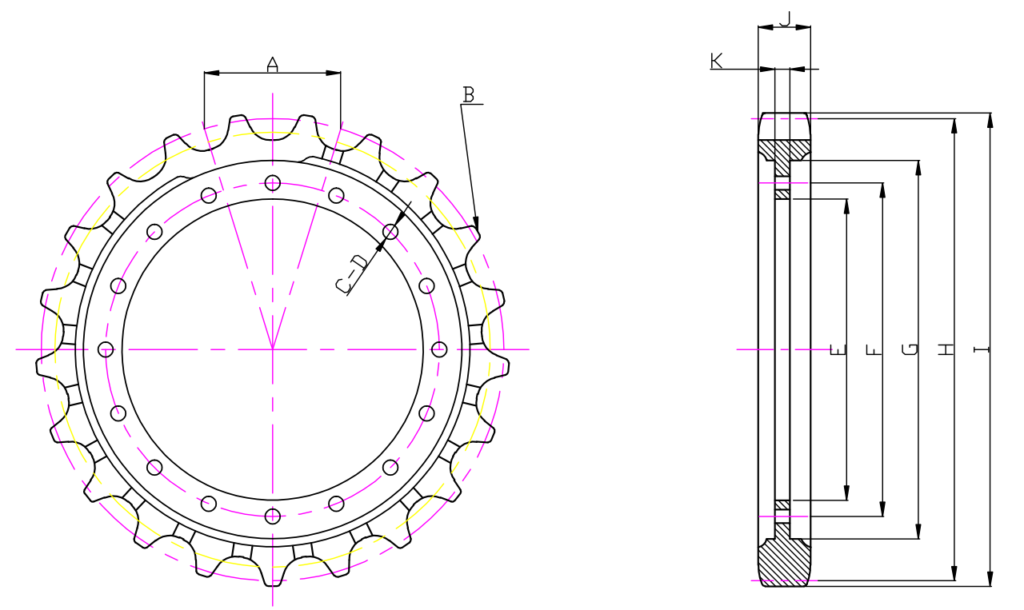

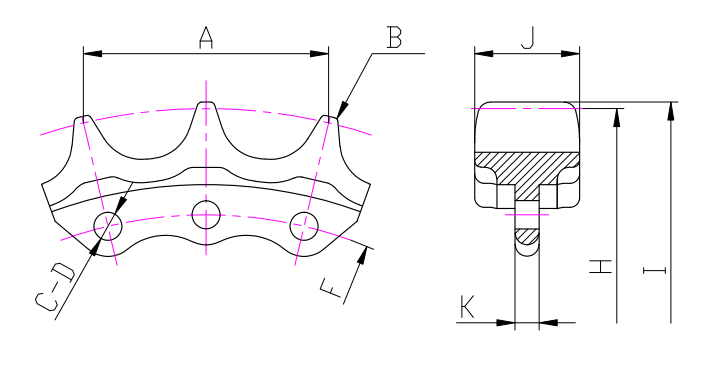

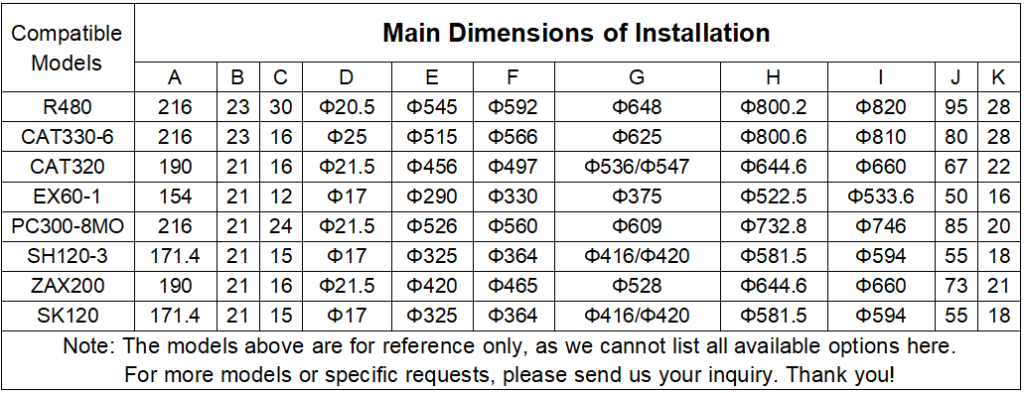

Especificações

Modelos de produtos

Processo de produção

- Forjamento em bruto: barras de aço de liga de alta qualidade são selecionadas para forjamento isotérmico para garantir que a estrutura interna seja densa e uniforme.

- Tratamento térmico: primeiro têmpera e depois revenimento, e então revenimento térmico para eliminar o estresse interno; o equilíbrio entre dureza e tenacidade torna a roda dentada menos propensa a rachar em ambientes de alto torque.

- Usinagem CNC: o corte preciso é realizado por meio do centro de usinagem CNC de ligação de cinco eixos, e cada superfície do dente é polida repetidamente para garantir a faixa de tolerância e o acabamento da superfície.

- Reforço de superfície: tratamento de nitretação ou fosfatação de alta temperatura, combinado com granalhagem para eliminar tensões residuais e melhorar a vida útil da fadiga.

- Inspeção de qualidade: equipado com equipamentos de inspeção avançados, como três coordenadas, testador de dureza, perfilômetro, etc., inspeção completa de vários indicadores, como tamanho, dureza, qualidade da superfície, detecção de falhas de partículas magnéticas, etc.

- Teste de equilíbrio dinâmico: A bancada de teste de montagem simula a operação do veículo real, detecta vibração e aumento de temperatura e garante que os produtos enviados atendam aos requisitos de uso 100%.

Embalagem e Envio

Vantagens da fábrica

Ao escolher um fabricantes de rodas dentadas para escavadeiras, muitos usuários estão mais preocupados com a falta de garantia de qualidade e o longo ciclo de entrega. Como fabricante profissional com 14 anos de experiência na fabricação de chassis, a GFM não só possui um processo de produção maduro e estável, como também está equipada com um sistema completo de gestão da qualidade e um processo de serviço personalizado, flexível e eficiente.

Fábrica própria, controle de qualidade total

A fábrica da GFM tem uma oficina de produção moderna equipada com equipamentos essenciais, como forno de tratamento térmico, centro de usinagem CNC, centro de usinagem vertical, equipamento de engrenagem CNC, instrumento de medição de três coordenadas, etc., para garantir que cada roda dentada enviada possa suportar o teste de ambiente de uso severo.

Construímos nosso próprio sistema de armazenamento de materiais e mantemos relações de cooperação estáveis com diversos grandes grupos siderúrgicos nacionais. Realizamos testes de desempenho físico e químico nas matérias-primas assim que elas chegam para garantir que a qualidade do produto seja controlada desde a origem.

Equipe profissional, suporte ao desenvolvimento personalizado

Para atender às condições especiais de trabalho de diferentes clientes, contamos com uma equipe profissional composta por engenheiros, mestres de moldes e especialistas em controle de qualidade, que podem responder rapidamente às necessidades de personalização do cliente, seja em formato de dente não padronizado, estrutura de roda dentada reforçada ou design modificado para combinar com passo de esteira especial.

Ao mesmo tempo, também aceitamos pedidos OEM/ODM e podemos personalizar a aparência, a marca e o design das soluções de embalagem de acordo com os requisitos da marca do cliente, apoiando modelos de cooperação estáveis e de longo prazo.

Escolher uma roda dentada de alta qualidade não só prolonga a vida útil do XCMG XE370, como também protege o andamento do seu projeto e os custos operacionais. A GFM espera se tornar sua parceira confiável de fornecimento de rodas dentadas a longo prazo, com fabricação profissional e serviços atenciosos para ajudar todos os seus projetos de engenharia a avançarem com eficiência!

Se precisar de amostras, orçamentos ou serviços personalizados, entre em contato conosco. Forneceremos consultoria e soluções profissionais o mais breve possível.

SOLICITE UM ORÇAMENTO AGORA

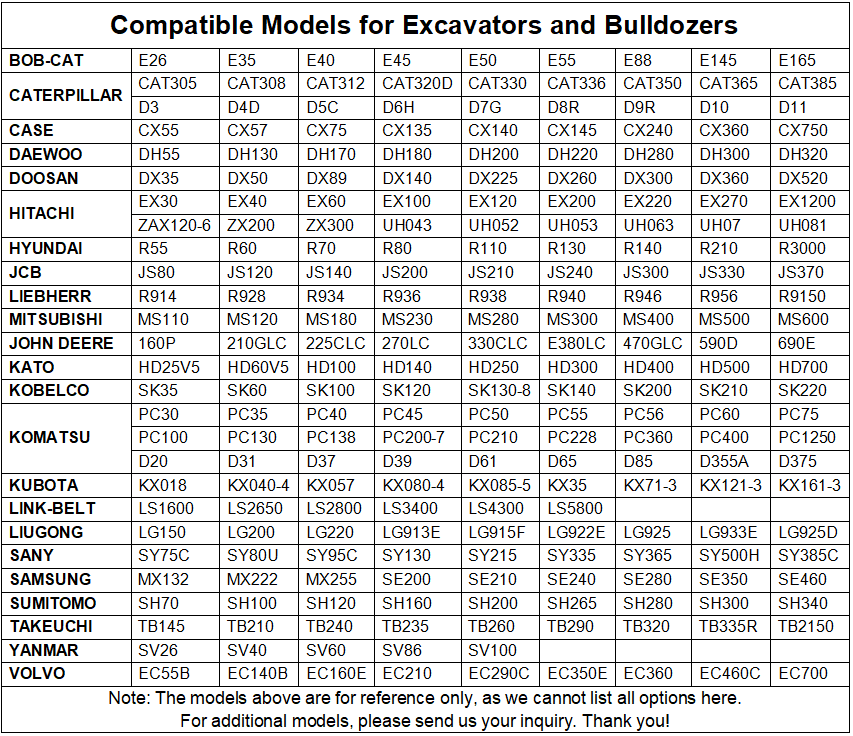

Fundada em 2011, a Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd. é uma fabricante experiente especializada em peças de reposição para escavadeiras e tratores de esteira, como peças para material rodante (rolos de esteira, rolos superiores, rodas-guia, rodas dentadas, sapatas de esteira, correntes de esteira, grupos de esteira), parafusos, porcas, pinos, buchas e muito mais. Cobrimos e mantemos em estoque uma ampla gama de peças aplicáveis à maioria das marcas e modelos disponíveis no mercado. As marcas compatíveis incluem Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., abrangendo as principais marcas do mercado.

Perguntas frequentes

Somos um fabricante experiente. Nossa fábrica está localizada em Xiamei Town, Quanzhou. Sua visita é muito bem-vinda.

Forneça-nos o modelo correto da máquina, o número da peça ou algumas especificações. Caso não sejam itens padrão, envie os desenhos.

Geralmente aceitamos T/T; outros termos podem ser negociados.

Claro que sim. Oferecemos serviço OEM. Se você tiver amostras ou desenhos, juntamente com uma solicitação de grande quantidade, podemos personalizar os produtos e oferecer suporte técnico profissional.

A GFM estabeleceu um sistema completo de controle de qualidade, meio ambiente e segurança. Todas as peças passam por rigorosos testes e medidas de controle de qualidade antes da distribuição. Nossa fábrica segue rigorosos padrões de segurança e regulamentações ambientais nos processos de fabricação.

SOLICITE UM ORÇAMENTO AGORA

Produtos relacionados

- TREM RODANTE

Roda de corrente para escavadeira CAT E305.5