Índice

- Overview of Excavator Sprockets: Function and Importance

- Common Types of Excavator Sprockets and Application Scenarios

- GFM’s Material Selection and Wear Resistance

- GFM’s Manufacturing Advantages: Technology and Process

- GFM Custom Services and Model Compatibility

- Global Client Testimonials: Why Choose GFM

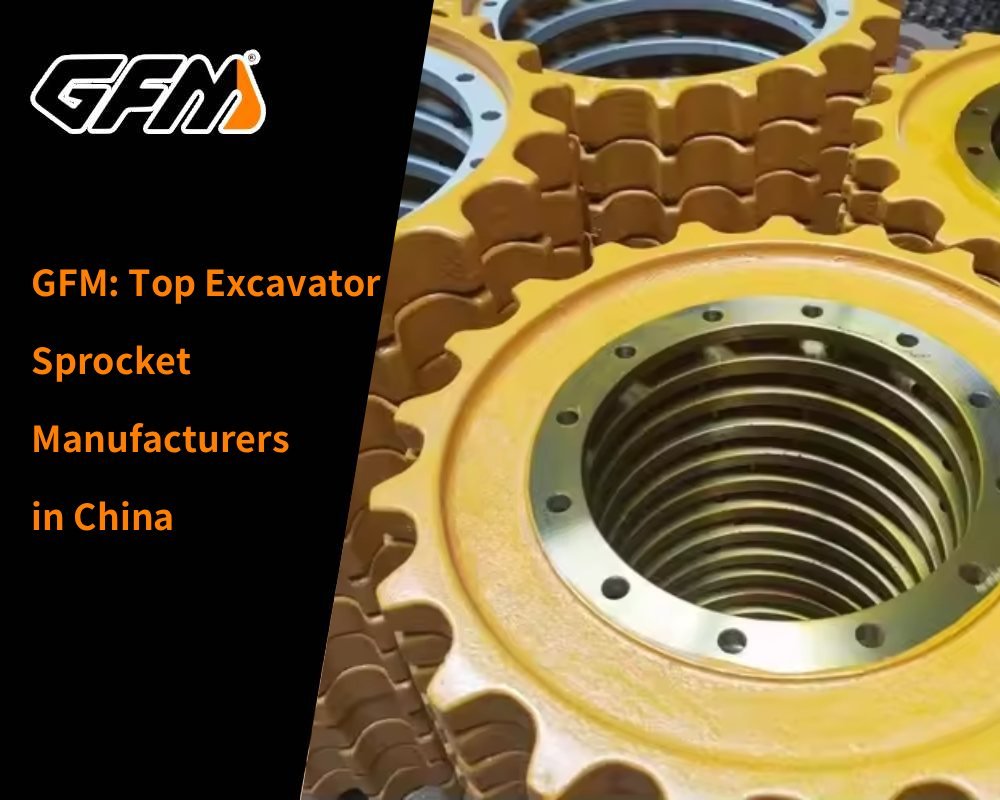

Overview of Excavator Sprockets: Function and Importance

- Core Power Transmission: Sprockets are a key component of the excavator track system, transferring engine power to the tracks for forward, backward, and turning movements.

- Load Bearing and Impact Resistance: Sprockets endure significant impact loads and friction during operation, ensuring stable machine performance.

- Impact on Construction Efficiency: The quality of sprockets directly affects work efficiency; worn or damaged sprockets can cause track slippage, increased vibration, and even downtime for repairs.

- Extend Equipment Life: High-quality sprockets maintain stable performance under heavy loads and complex conditions, prolonging machine lifespan and reducing maintenance costs.

Since its establishment in 2011, GFM has focused on the development and manufacturing of excavator sprockets, accumulating over 14 years of professional experience. Through scientific design and strict manufacturing processes, GFM provides reliable sprocket solutions for customers.

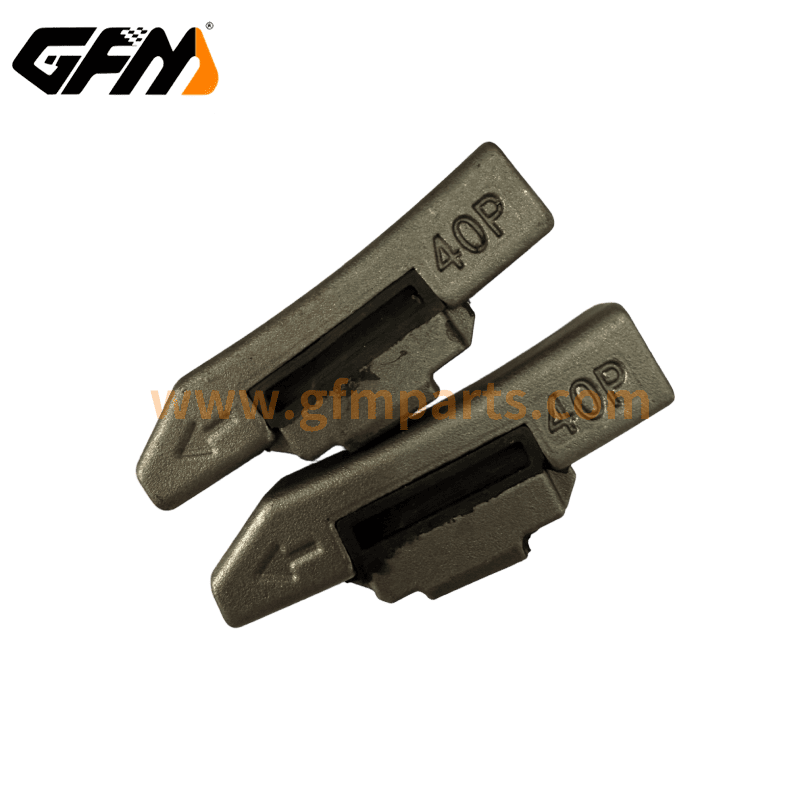

Common Types of Excavator Sprockets and Application Scenarios

Sprockets can be classified based on working conditions and load requirements:

- Standard Sprockets: Suitable for light to medium projects and standard earthmoving operations, simple structure, easy maintenance, cost-effective.

- Thickened Sprockets: Designed for heavy-duty operations such as mining and large-scale infrastructure, with reinforced teeth for improved wear resistance and load capacity.

- Heavy-Duty Sprockets: Applied in extreme conditions such as rock excavation and debris handling, made of high-strength alloy steel with heat treatment to enhance impact resistance and durability.

GFM provides compatible sprockets for various excavator models, ensuring efficient power transmission. Customers can choose the appropriate sprocket according to machine tonnage, work environment, and load intensity to extend service life and improve efficiency.

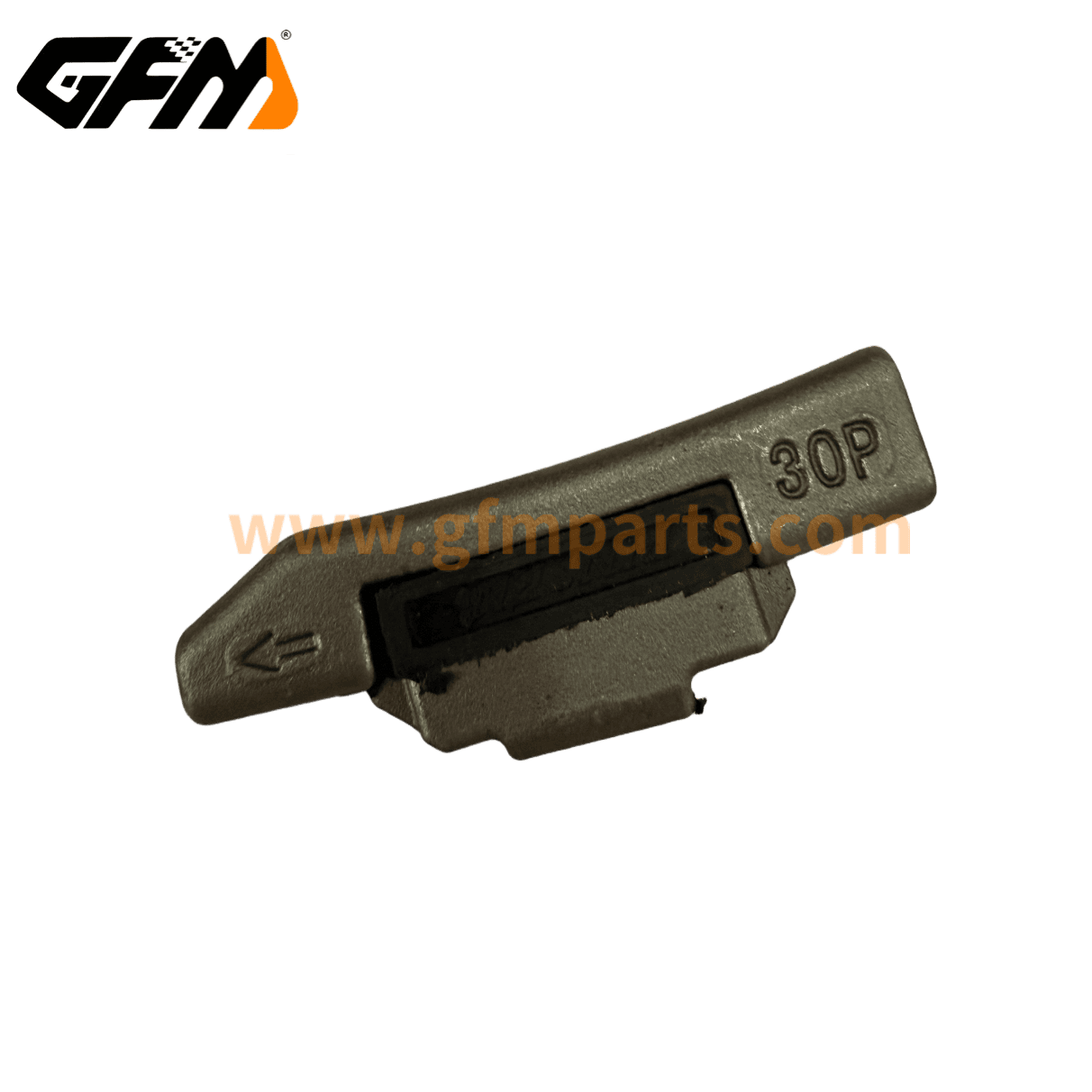

GFM’s Material Selection and Wear Resistance

The performance of sprockets largely depends on material quality. GFM strictly controls material selection to ensure stable and durable sprockets under various working conditions:

- High Manganese Steel: Suitable for medium and light-duty operations, offering impact resistance and wear performance.

- Liga de aço: For heavy-duty conditions, enhanced with elements like molybdenum and nickel for higher hardness and toughness.

- Tratamento térmico: GFM applies carburizing, quenching, and tempering to achieve high surface hardness while maintaining core toughness, balancing wear resistance and fracture prevention.

Each sprocket undergoes rigorous quality inspection to ensure stable performance in long-term, continuous operations. GFM sprockets are widely used in domestic and international projects, maintaining reliable operation over time.

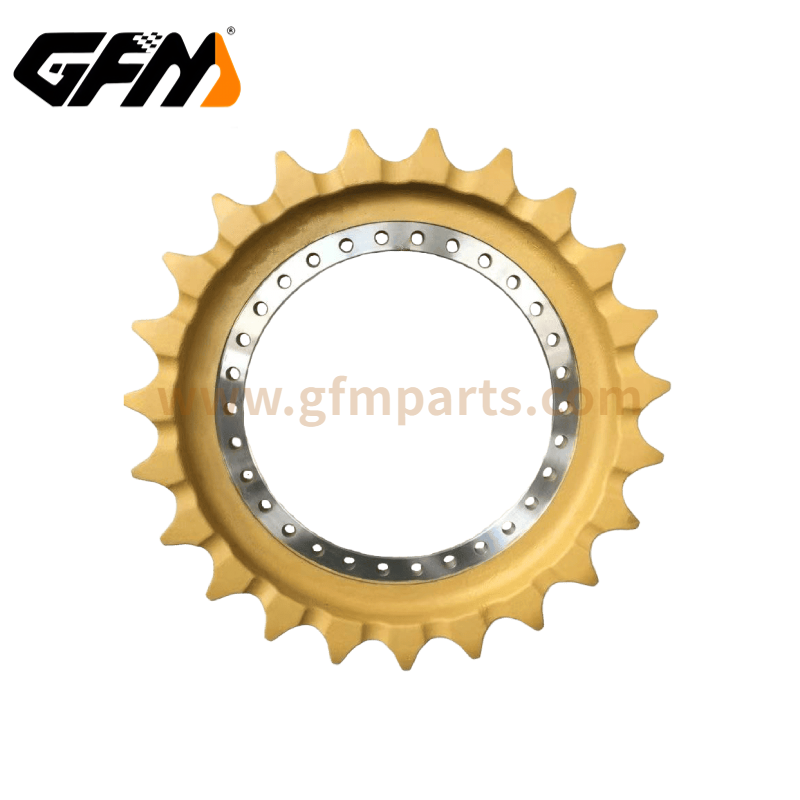

GFM’s Manufacturing Advantages: Technology and Process

GFM has clear advantages in sprocket manufacturing:

- High-Precision Casting: Advanced casting reduces porosity and impurities, increasing overall structural strength.

- Automated Processing: Equipped with CNC lathes and gear grinding machines for high-precision tooth profiles.

- Comprehensive Inspection System: CMM (Coordinate Measuring Machine) and hardness testers ensure each sprocket meets dimensional and performance standards.

- Certificações e Normas: Products comply with ISO9001 and are tested by third-party agencies for wear resistance and material quality.

When selecting sprockets, customers can assess the manufacturer’s technical capabilities and inspection system to ensure reliable, long-lasting products.

GFM Custom Services and Model Compatibility

GFM offers full-service sprocket solutions, ensuring each excavator receives the best-matched sprockets:

Customization Process:

- Requirement Submission: Customers provide excavator model, working conditions, and special requirements, including sprocket size, number of teeth, and material.

- Feasibility Assessment: GFM’s technical team evaluates requirements and proposes optimized designs to enhance wear resistance and power transmission efficiency.

- Sample Confirmation: Sprocket samples are produced and sent to the customer for approval to ensure dimensions, tooth profile, and material meet specifications.

- Mass Production: After contract signing, production is scheduled to ensure timely and reliable delivery.

- Suporte pós-venda: Installation guidance, technical support, and maintenance advice are provided to ensure long-term performance.

GFM offers sprockets in various sizes and materials for small to large excavators, fully compatible with mainstream brands including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Sany, XCMG, Shantui, and more. This ensures each sprocket perfectly matches the equipment, extending service life and improving operational efficiency.

Global Client Testimonials: Why Choose GFM

GFM has provided sprocket solutions for domestic and international engineering companies, earning widespread trust:

- Successful Cases: A large European infrastructure company reported extended maintenance cycles and reduced downtime after using GFM sprockets.

- Adaptation to Complex Conditions: GFM sprockets perform reliably in high-temperature deserts, frozen northern climates, and high-humidity regions.

- Customer Feedback: Clients recognize GFM sprockets for their stability, durability, quick responsiveness, and professional after-sales service.

When selecting a sprocket supplier, referring to GFM’s global cases helps evaluate technical capability, experience, and after-sales service to ensure efficient and reliable equipment operation.

| Obtenha um orçamento rápido e gratuito | E-mail: henry@gfmparts.com | Whatsapp: +86 17705953659 |

With 14 years of professional manufacturing experience, advanced materials and processes, extensive customization capabilities, and global client trust, GFM has become a top fabricantes de rodas dentadas para escavadeiras in China and a reliable fornecedor de rodas dentadas para escavadeira.

Choosing GFM ensures high-quality, durable sprockets, improves overall excavator performance, reduces maintenance costs, and guarantees reliable operation in various working conditions. GFM is committed to providing tailor-made high-quality sprocket solutions, making it a trusted long-term partner for customers worldwide.