Как производитель деталей для экскаваторовмы знаем, что в тяжелых условиях эксплуатации эффективная работа оборудования зависит от нормальной работы каждого ключевого компонента.

Оглавление

Ключевые моменты

При техническом обслуживании экскаваторов существует несколько основных принципов, которые нельзя игнорировать:

- Общая стратегия обслуживанияРазличные системы экскаватора – двигатель, гидравлическая система, шасси, дополнительное оборудование, электросистема и кабина – являются нервным центром работы оборудования. Согласно данным маркетинговых исследований, отказы экскаваторов (80%) могут быть связаны с дисбалансом гидравлической системы и двигателя. Поэтому разработка плана технического обслуживания, охватывающего всю систему, является ключом к продлению срока службы оборудования.

- Профилактическое обслуживание: Регулярные осмотры и профилактическое обслуживание могут снизить частоту отказов. Согласно статистике, профилактическое обслуживание может сократить время простоя оборудования на 30% и снизить затраты на техническое обслуживание примерно на 20%.

- Своевременно заменяйте детали: В процессе эксплуатации оборудования, контролируя показатели оборудования (такие как давление масла, температура гидравлического масла и данные о вибрации), можно вовремя распознать ранние признаки ухудшения состояния компонентов, чтобы предотвратить перерастание небольших проблем в серьезные поломки.

- Стандартизированный процесс: Разработать и внедрить стандартизированные процессы закупки и замены деталей, чтобы гарантировать соответствие каждой операции техническим параметрам оборудования и стандартам безопасности, тем самым повышая общую эффективность и безопасность эксплуатации.

Список деталей экскаватора и их функции

Компоненты каждой подсистемы выполняют важные функции в ключевых системах экскаватора. Ниже представлен подробный анализ каждой основной системы:

Система двигателя

- Основная функция: Двигатель, «сердце» экскаватора, отвечает за преобразование топлива в механическую энергию и обеспечение стабильной работы всего оборудования. Современные двигатели экскаваторов обычно имеют выходную мощность от 100 до 400 лошадиных сил и должны соответствовать стандартам выбросов ISO или EPA.

- Основные части: Поршень, цилиндр, коленчатый вал, клапанная система и система подачи топлива. Высокоточная механическая и термическая обработка позволяют повысить эффективность двигателя на 5%-10%. Регулярный контроль давления масла (обычно поддерживаемого на уровне 3-4 бар) и температуры (поддерживаемой на уровне 80-90°C) является залогом его эффективной работы.

Гидравлическая система

- Основная функция: Гидравлическая система обеспечивает точность работы стрелы, ковша и других навесных устройств экскаватора. Давление в гидравлической системе высокопроизводительного оборудования обычно достигает 300–350 бар.

- Основные части: Гидравлический насос, гидроцилиндр, масляный бак, клапан и фильтр. Качество гидравлического масла напрямую влияет на эффективность системы. Отраслевые данные показывают, что использование высокоэффективного гидравлического масла может снизить энергопотребление примерно на 5%. Регулярная замена гидравлического масла (обычно каждые 2000–3000 рабочих часов) и фильтров предотвращает загрязнение системы, обеспечивая скорость реагирования и точность управления.

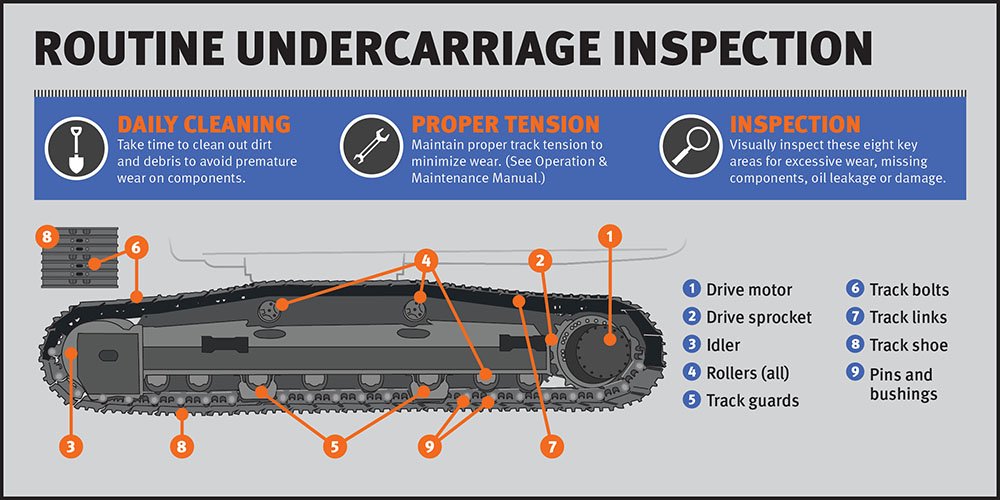

Компоненты шасси

- Основная функция: Система шасси поддерживает и передает нагрузку всей машины, обеспечивая устойчивость оборудования на сложных рельефах. Конструкция шасси современных экскаваторов ориентирована на износостойкость и амортизацию, а скорость износа гусениц обычно необходимо проверять каждые 1000 рабочих часов.

- Основные части: Ходовая часть, гусеница, система амортизации и подвеска. Данные показывают, что натяжение гусеницы напрямую влияет на устойчивость оборудования, а правильная регулировка может снизить частоту отказов шасси примерно на 15%.

Аксессуары

- Основная функция: Принадлежности определяют область применения экскаватора в различных условиях работы, таких как дробление, бурение, погрузка и т.д. В зависимости от интенсивности работы и окружающей среды скорость износа принадлежностей может быть увеличена на 20%-30%.

- Основные части: Рукоять, ковш, гидромолот и грейфер. При проектировании необходимо учитывать прочность и износостойкость материалов. Использование высокопрочных сплавов может продлить срок службы оснастки более чем на 20%.

Электрическая система

- Основные функции: Электрическая система объединяет функции управления, мониторинга и обратной связи и отслеживает состояние оборудования в режиме реального времени с помощью высокоточных датчиков и модулей управления. Данные показывают, что точная калибровка приборов может увеличить общую скорость реагирования системы на 5%–8%.

- Основные части: Электронный блок управления, датчик, приборная панель и система линий. Регулярная проверка состояния электроблока управления и линий на предмет износа для обеспечения точного сбора данных — ключ к стабильной работе системы.

Такси

- Основные функции: Кабина не только обеспечивает безопасную и комфортную рабочую среду для оператора, но и позволяет осуществлять мониторинг и управление оборудованием в режиме реального времени. Эргономичный дизайн кабины способствует снижению утомляемости оператора на 15%-20%.

- Основные части: Сиденья, приборы, система кондиционирования воздуха и ремни безопасности. Высококачественная конфигурация кабины может значительно повысить эффективность и безопасность работы, особенно в условиях высоких или низких температур. Стабильная работа системы кондиционирования воздуха особенно важна.

Советы по обслуживанию деталей экскаватора

Техническое обслуживание системы двигателя

Регулярное техническое обслуживание является залогом долгой работы двигателя:

- Замена масла: Рекомендуется менять масло каждые 250–500 часов работы и использовать высококачественное масло, соответствующее стандартам API или ACEA.

- Система охлаждения: Проверяйте радиатор и вентилятор каждый месяц, чтобы поддерживать соотношение охлаждающей жидкости на рекомендуемом уровне (обычно это смесь 50/50).

- Топливная система: Регулярно прочищайте топливную форсунку и фильтр, чтобы эффективность сгорания оставалась выше 95%.

Техническое обслуживание гидравлической системы

Обеспечьте эффективное реагирование и точное управление гидравлической системой:

- Техническое обслуживание гидравлического масла: Меняйте гидравлическое масло каждые 2000–3000 часов. Качество масла напрямую влияет на эффективность работы системы.

- Очистка фильтра: В зависимости от условий эксплуатации проверяйте и очищайте или заменяйте фильтр каждые 1000 часов, чтобы предотвратить засорение примесями.

- Проверка пломб: Регулярно проверяйте гидравлический насос и уплотнения клапанов, чтобы предотвратить утечки и падение давления.

Техническое обслуживание шасси

Устойчивость шасси — основа безопасности машины:

- Проверка пути: Проверяйте износ гусеницы каждые 500 часов, при необходимости отрегулируйте натяжение или замените сильно изношенные детали.

- Техническое обслуживание смазки: Смазывайте ходовые части до и после ежедневной эксплуатации, чтобы уменьшить трение и тепловые повреждения.

- Система амортизации: Регулярно проверяйте систему амортизации на предмет утечки масла или ухудшения ее характеристик, чтобы всегда быть уверенным в наилучшем состоянии подвески.

Техническое обслуживание аксессуаров

Аксессуары напрямую влияют на эффективность работы и точность операций:

- Проверка соединения: Перед каждой операцией и после нее проверяйте надежность соединения рукояти ковша и своевременно подтягивайте его, если оно ослаблено.

- Мониторинг износа: В зависимости от интенсивности эксплуатации проверка износа вспомогательных агрегатов проводится каждые 500 часов, чтобы убедиться в отсутствии трещин и усталости деталей.

Техническое обслуживание электрической системы

Электрическая система, являясь «нервным центром» оборудования, требует высокой надежности:

- Обнаружение линии: Регулярно проверяйте электрический блок управления и систему линий, чтобы предотвратить короткие замыкания, вызванные старением или влажностью.

- Калибровка датчика: Калибровку датчиков и приборов следует проводить каждые 1000 часов для обеспечения точности данных.

- Резерв запасных частей: Рекомендуется создать библиотеку запасных частей для основных электрических деталей на случай чрезвычайных ситуаций.

Техническое обслуживание кабины

Хорошее состояние кабины связано с безопасностью оператора и эффективностью работы:

- Очистка окружающей среды: Регулярно очищайте кабину изнутри и снаружи, чтобы поддерживать свободный обзор и не допускать отражения от приборов, влияющего на работу.

- Проверка оборудования безопасности: Регулярно проверяйте ремни безопасности, сиденья и приборную панель, чтобы убедиться в том, что средства безопасности не устарели и не вышли из строя.

- Система кондиционирования воздуха: В экстремальных климатических условиях техническое обслуживание системы кондиционирования воздуха особенно важно. Проверяйте её раз в квартал, чтобы обеспечить эффективную работу системы.

Признаки необходимости замены деталей экскаватора

Регулярно проверяя данные о работе оборудования, вы можете эффективно выявлять ранние признаки приближающегося выхода из строя деталей:

Система двигателя

- Общие признаки: необычный шум, повышенная вибрация и снижение выходной мощности.

- Справочные данные: Загрязнение масла или падение давления 5%-10% может указывать на то, что внутренние детали сильно изношены, и основные компоненты, такие как поршневые кольца и коленчатые валы, требуют своевременной замены.

Гидравлическая система

- Распространенные признаки: задержка срабатывания, утечка гидравлического масла и снижение эффективности гидравлического насоса.

- Справочные данные: При падении рабочего давления гидравлической системы более чем на 10% или аномальном повышении температуры гидравлического масла (превышающей рекомендуемое значение более чем на 10°C) необходимо проверить уплотнения гидравлического цилиндра, насоса и клапанов.

Компоненты шасси

- Распространенные признаки: сильный износ дорожки, трещины или разрывы, неустойчивая походка.

- Справочные данные: Данные испытаний показывают, что скорость износа гусениц превышает 30% или реакция системы амортизации падает более чем на 15%, и соответствующие детали следует своевременно заменить или отремонтировать.

Аксессуары

- Распространенные признаки: Ковш или гидромолот имеют очевидные трещины, а скорость износа превышает 20% проектного срока службы.

- Справочные данные: Если соединение навесного оборудования ослаблено или возникает ненормальная вибрация, это может повлиять на общую эффективность работы и требует своевременного ремонта или замены.

Электрическая система

- Распространенные признаки: ненормальные показания приборов, частые сигналы тревоги и отказы датчиков.

- Справочные данные: Если колебания температуры или напряжения в электрическом блоке управления превышают стандартный диапазон ±10%, рекомендуется проверить печатную плату и датчик, чтобы предотвратить масштабные сбои.

Такси

- Общие признаки: Медленная реакция приборов и пультов, старение оборудования безопасности.

- Справочные данные: Если срок службы таких компонентов, как сиденья и приборные панели, значительно ниже ожидаемого (обычно 5–7 лет), следует рассмотреть возможность обновления соответствующего оборудования для обеспечения безопасной эксплуатации.

Как приобрести и заменить детали экскаватора

Закупка и замена играют важнейшую роль в обслуживании оборудования. Стандартизированный процесс и строгие эксплуатационные процедуры могут обеспечить долгосрочную и стабильную работу оборудования.

Покупка запчастей

- Выбор канала сбыта: Рекомендуется сначала выбрать оригинального производителя или сертифицированного дилера, чтобы гарантировать соответствие качества запчастей стандартам ISO, CE или национальным стандартам. Данные показывают, что использование оригинальных запчастей может снизить частоту отказов, вызванных несоответствием деталей, примерно на 20%.

- Цена и обслуживание: Сравнивая цены по разным каналам, необходимо обращать внимание на условия гарантии и послепродажного обслуживания. Перед покупкой рекомендуется ознакомиться с данными о характеристиках и отзывами пользователей, чтобы убедиться в их высокой надежности и долговечности.

Замена деталей

- Профессиональная эксплуатация: замена деталей должна выполняться квалифицированными специалистами для обеспечения безопасности эксплуатации и совместимости системы. Стандартизированные рабочие процедуры (такие как подробные руководства по эксплуатации и видеоуроки) могут снизить частоту ошибок при эксплуатации до менее чем 5%.

- Управление записями: рекомендуется использовать электронную файловую систему для подробной регистрации данных по каждой замене и техническому обслуживанию, чтобы обеспечить поддержку данных для будущего прогнозирования и предотвращения неисправностей.

Обеспечить совместимость

- Техническое соответствие: Перед покупкой обязательно проверьте модель детали, партию производства и параметры оборудования. Рекомендуется ознакомиться с руководством по техническому обслуживанию оборудования и списком деталей, рекомендованным производителем, чтобы убедиться, что заменяемые детали соответствуют оригинальной конфигурации.

- Стандарты сертификации: закупаемые детали должны соответствовать соответствующим стандартам сертификации, чтобы гарантировать стабильную работу оборудования в условиях высоких нагрузок, при этом в качестве доказательства используются данные отчета стороннего испытательного агентства.

Устранение распространенных неисправностей деталей экскаваторов

Крайне важно разработать научный процесс устранения распространенных неисправностей в различных системах:

Проблемы с гидравлической системой

- Распространенные проблемы: загрязнение гидравлического масла, засорение масляного контура и старение уплотнений.

- Стратегия устранения неисправностей: Согласно анализу данных, когда концентрация примесей в гидравлическом масле превышает 5%, масло необходимо заменить; регулярная очистка гидравлической системы и проверка давления в масляном контуре (поддерживаемого в стандартном диапазоне 300–350 бар) могут эффективно предотвратить неисправности.

Проблемы с электрической системой

- Распространенные проблемы: старение линии, короткое замыкание, несоответствие калибровки датчика.

- Стратегия устранения неисправностей: используйте профессиональные контрольно-измерительные приборы для регулярной проверки электрического блока управления, чтобы убедиться, что колебания напряжения и температуры находятся в разумном диапазоне ±10%, а также периодически калибруйте и проверяйте основные датчики.

Проблемы с шасси

- Распространенные проблемы: ослабленные гусеницы, неисправность системы амортизации, недостаточная смазка.

- Стратегия устранения неисправностей: регулярно подтягивайте соединительные детали шасси, следите за натяжением и износом гусениц, а также своевременно регулируйте или заменяйте изнашиваемые детали, если данные отклоняются от нормы.

Проблемы с двигателем

- Распространенные проблемы: загрязнение масла, засорение системы охлаждения и плохая подача топлива.

- Стратегия устранения неисправностей: регулярно контролируйте давление и температуру масла, следите за тем, чтобы соотношение охлаждающей жидкости находилось в рекомендуемом диапазоне, а также очищайте топливную форсунку, чтобы обеспечить поддержание эффективности сгорания выше 95%.

Часто задаваемые вопросы

В1: Какая часть экскаватора наиболее важна для регулярного технического обслуживания?

A1: Двигатель и гидравлическая система являются основой экскаватора. Данные показывают, что частота отказов этих двух компонентов составляет почти 80% от общего числа отказов. Регулярное техническое обслуживание этих двух компонентов позволяет эффективно предотвратить большинство отказов и обеспечить долгосрочную эксплуатацию оборудования.

В2: Как часто следует менять воздушный фильтр экскаватора?

A2: Рекомендуется проверять каждые 500–1000 часов или раз в квартал в зависимости от условий эксплуатации и интенсивности использования. Данные показывают, что в условиях повышенной запыленности периодичность замены следует увеличивать, чтобы предотвратить снижение эффективности двигателя из-за плохой фильтрации воздуха.

В3: Можно ли использовать неоригинальные детали для ремонта экскаватора?

A3: Да, но необходимо выбирать высококачественные сертифицированные и протестированные запчасти. Статистика показывает, что использование сертифицированных запчастей может снизить частоту отказов оборудования примерно на 15%, обеспечивая при этом стабильную работу оборудования в условиях высоких нагрузок.

В4: Как определить правильные запасные части для экскаватора?

A4: Рекомендуется проверить модель детали, параметры и партию производства, а также руководство по техническому обслуживанию оборудования и рекомендации производителя. Использование профессиональных инструментов для сравнения новых и старых деталей позволяет эффективно предотвратить сбои системы, вызванные несоответствием компонентов.

В5: Какие инструменты необходимы для замены деталей экскаватора?

A5: К распространённым инструментам относятся гаечные ключи, отвёртки, гидравлическое подъёмное оборудование, смазочные инструменты и контрольно-измерительные приборы. Набор инструментов зависит от проекта замены, а набор стандартных инструментов может снизить частоту ошибок при эксплуатации до менее чем 5%.

| Получите быструю бесплатную расценку | Электронная почта: henry@gfmparts.com | Вотсап: +86 17705953659 |

Будь то регулярное профилактическое обслуживание или устранение внезапных неисправностей, научно обоснованные и систематические эксплуатационные процедуры могут значительно повысить эффективность работы оборудования и продлить срок его службы. Для GFM и её клиентов создание комплексной системы технического обслуживания оборудования является основополагающей гарантией инженерной эффективности и безопасности. Постоянный контроль состояния оборудования, своевременное обновление данных о техническом обслуживании и использование высококачественных запасных частей — единственный способ обеспечить оптимальную производительность экскаваторов в условиях высокой конкуренции.