| Оглавление |

| 1. International and domestic brands of excavators 2. Analysis of the diversity of excavator styles 3. Types of excavator functions 4. Guide to excavator selection decisions |

With the acceleration of urbanization and the continuous expansion of infrastructure construction, excavators play an irreplaceable role in earthwork excavation, demolition, loading, etc. The major global markets are gradually transforming towards intelligence, digitalization, environmental protection and energy saving, and the supporting excavator parts supply chain is also constantly improving. As an производитель деталей для экскаваторов, GFM’s products must not only meet the requirements of efficient equipment operation, but also meet the market’s demand for intelligent and personalized solutions.

International and domestic brands of excavators

Technology and service advantages of international brands

Caterpillar

- Technical strength: Relying on powerful hydraulic systems and precision control technology, Caterpillar’s equipment still maintains efficient and stable operating performance under heavy loads and extreme working conditions.

- Global service network: The perfect after-sales and maintenance system makes equipment maintenance and parts replacement more convenient, ensuring efficient operation of equipment worldwide.

- R&D innovation: Continuously launch intelligent monitoring, remote diagnosis and automation control systems to improve operation safety and efficiency.

Komatsu and Hitachi

- High-efficiency operation: With advanced digital control systems, Komatsu and Hitachi’s excavators are at the forefront of the industry in terms of energy saving, environmental protection and operation accuracy.

- Customized solutions: Specially designed product lines are launched for different working conditions to meet the diverse needs of construction, mining and special projects.

- User experience: Focus on operating comfort and intelligent human-machine interaction, so that drivers can maintain high efficiency and low fatigue during long-term operations.

Cost-effectiveness and localized services of domestic brands

SANY and XCMG

- Cost-effectiveness advantage: Under the premise of ensuring high performance, domestic brands are more competitive in price and operating costs.

- Local service response: The extensive maintenance network and spare parts supply chain can quickly respond to market demand and reduce construction delays caused by equipment failures.

- Technical optimization: In view of the complex domestic construction environment, the product is continuously optimized in terms of hydraulic system stability, anti-wear design and intelligent monitoring to improve the overall service life.

Key factors for brand selection

- After-sales service and global network: Equipment maintenance, spare parts supply and emergency response are the key to ensuring the progress of the project; high-quality brands can often provide comprehensive global and regional service support.

- Technology R&D and innovation capabilities: Advanced intelligent control systems, environmental protection and energy-saving technologies and customized solutions are important manifestations of the brand’s core competitiveness.

- Market reputation and actual cases: By examining historical engineering cases and user feedback, select brands that perform well in actual working conditions to provide guarantees for the long-term operation of equipment.

Analysis of the diversity of excavator styles

Different styles of excavators have their own expertise. For different working conditions and construction requirements, the style design directly affects the operating efficiency and economic benefits of the equipment.

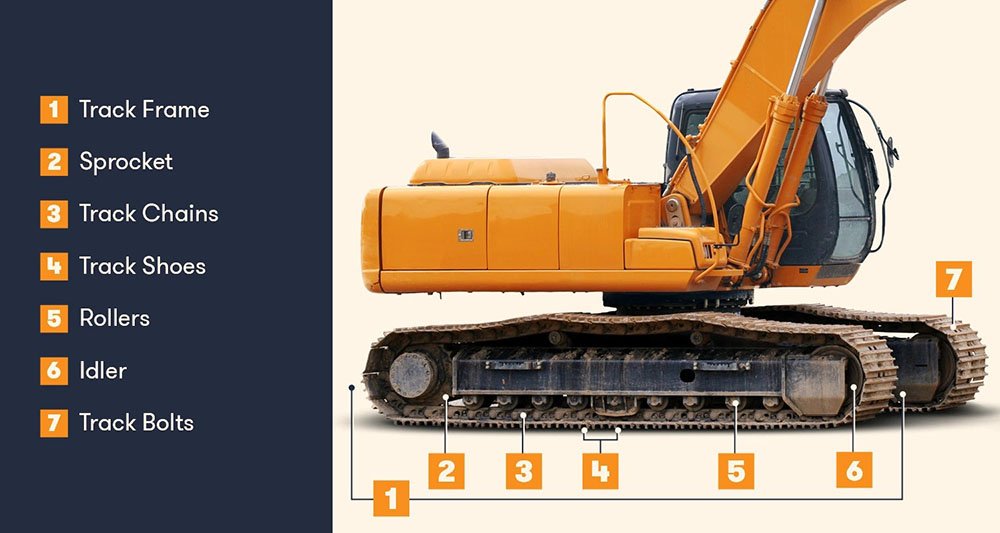

Crawler excavator

- Конструктивные особенности: The crawler chassis can maintain stability on muddy, soft and uneven ground.

- Технические преимущества:

- High stability: The crawler disperses pressure, reduces ground loss, and is suitable for heavy loads and long-term continuous operations.

- Strong traction: It can still maintain high operating efficiency under extreme working conditions, especially suitable for mines, quarries and large earthwork projects.

- Сценарии применения: Mainly used for large-scale earthwork operations, foundation pit excavation and mining operations in construction.

Wheeled excavator

- Конструктивные особенности: Equipped with a wheeled chassis, it is flexible and has a fast moving speed.

- Технические преимущества:

- High mobility: It has significant advantages on urban roads and hardened roads, and is convenient for rapid conversion between multiple construction areas.

- Low noise and environmental protection: Some models use advanced noise reduction and low emission technologies, which meet urban environmental protection requirements.

- Сценарии применения: Suitable for municipal engineering, urban infrastructure construction and construction sites that require rapid dispatch.

Mini and small excavators

- Конструктивные особенности: small size, flexible operation, designed for narrow construction environments.

- Технические преимущества:

- Efficient operation: Even in limited spaces, it can complete fine earthwork, pipeline construction and landscaping operations.

- Economic efficiency: low fuel consumption, simple operation, suitable for small and medium-sized projects or urban renovation projects.

- Сценарии применения: indoor and outdoor municipal renovation, garden landscape design, interior decoration and small project construction.

Special and customized excavators

- Конструктивные особенности: Customized design according to specific working conditions (such as underwater, tunnels, ports), modular structure, convenient replacement of professional accessories.

- Технические преимущества:

- Adapt to extreme environments: Anti-corrosion, waterproof and seismic design are adopted under special working conditions to ensure the safe operation of equipment in harsh environments.

- Highly customized: Meet special engineering needs, such as demolition, breaking and high-precision operations, and improve work efficiency.

- Сценарии применения: Projects that require professional customized solutions such as tunnel construction, underwater operations, urban demolition and port engineering.

Excavator action type

Different tasks have different requirements for the performance and technical indicators of excavators. Through a detailed analysis of the action type, it can more accurately match the project requirements.

Earthwork and foundation pit excavation

- Technical requirements: high excavation depth, large bucket capacity and fast working cycle.

- Equipment matching: Medium and large crawler excavators are mostly used, and their powerful hydraulic system and high load capacity ensure continuous operation.

- Actual case: In large-scale urban construction, subway stations and high-rise building foundation pit excavation, equipment must take into account both efficiency and safety to ensure accurate scheduling of the construction site.

Building demolition and heavy-load demolition

- Technical requirements: precise control, strong vibration resistance and support of multi-functional accessories.

- Equipment matching: Some brands have launched excavators with special demolition models or equipped with demolition devices, which can not only ensure demolition efficiency but also reduce secondary damage in demolition tasks.

- Note: Demolition operations have high requirements for equipment operation stability and real-time monitoring. Intelligent systems can help operators accurately control demolition force and angle.

Material handling and loading operations

- Technical requirements: hydraulic systems with fast mode conversion, high grabbing accuracy and fast response.

- Equipment matching: Wheeled and small excavators perform well in this field, especially when equipped with intelligent grab systems, which can automatically adjust the grabbing force and operating angle.

- Benefit improvement: Efficient material handling can effectively shorten the construction period and reduce the overall cost of the project, which is suitable for logistics-intensive projects.

Special engineering applications: mines, tunnels and underwater operations

- Technical requirements: high durability in extreme environments, customized structures and special accessories support.

- Equipment matching: Special excavators usually adopt anti-corrosion, waterproof and high temperature resistant designs, and cooperate with special operation accessories to achieve precise operation.

- Cutting-edge technology: Modular design and real-time monitoring system enable the equipment to maintain efficient operation in high-risk environments, and optimize the operation process through big data analysis.

Excavator selection decision guide

Clarify engineering requirements and site environment

- Site terrain: Analyze environmental parameters such as soil quality, slope, humidity, etc. to determine the equipment’s requirements for stability, grip and anti-slip properties.

- Operation tasks: Distinguish between earthwork, demolition, loading or special engineering. Each task has specific requirements for equipment bucket capacity, excavation depth and operational flexibility.

Core technical indicators and performance parameters

- Hydraulic system and excavation torque: Efficient hydraulic system determines the response speed and overall energy efficiency of the operation, which directly affects the efficiency of earthwork and loading.

- Operation accuracy and intelligent monitoring: Advanced automatic control and sensor systems help achieve precise operations and reduce the risk of misoperation.

- Environmental protection and energy-saving indicators: New energy technology, low fuel consumption design and low emission system have gradually become important selection criteria in modern engineering.

Brand strength and after-sales support

- Service network coverage: Global or regional service centers and rapid response mechanisms ensure long-term and stable operation of equipment.

- Technical support and training: High-quality brands usually provide detailed operation training and technical guidance to improve the driver’s operating skills and safety.

- Accessories supply and customized solutions: As an accessories manufacturer, high-quality, modular replacement parts provided by companies such as GFM can reduce equipment downtime and extend the life cycle of equipment.

Return on investment and long-term operation considerations

- Life cycle cost: In addition to the initial purchase price, maintenance costs, parts replacement cycle and second-hand value retention rate must also be considered.

- Intelligent and automated upgrade potential: Choosing equipment with later upgrade space can enable the project to obtain higher investment returns in digital transformation.

- Actual cases and expert advice: Refer to successful cases and professional consulting opinions in the same industry to provide data support and actual verification for selection.

| Получите быструю бесплатную расценку | Электронная почта: henry@gfmparts.com | Вотсап: +86 17705953659 |