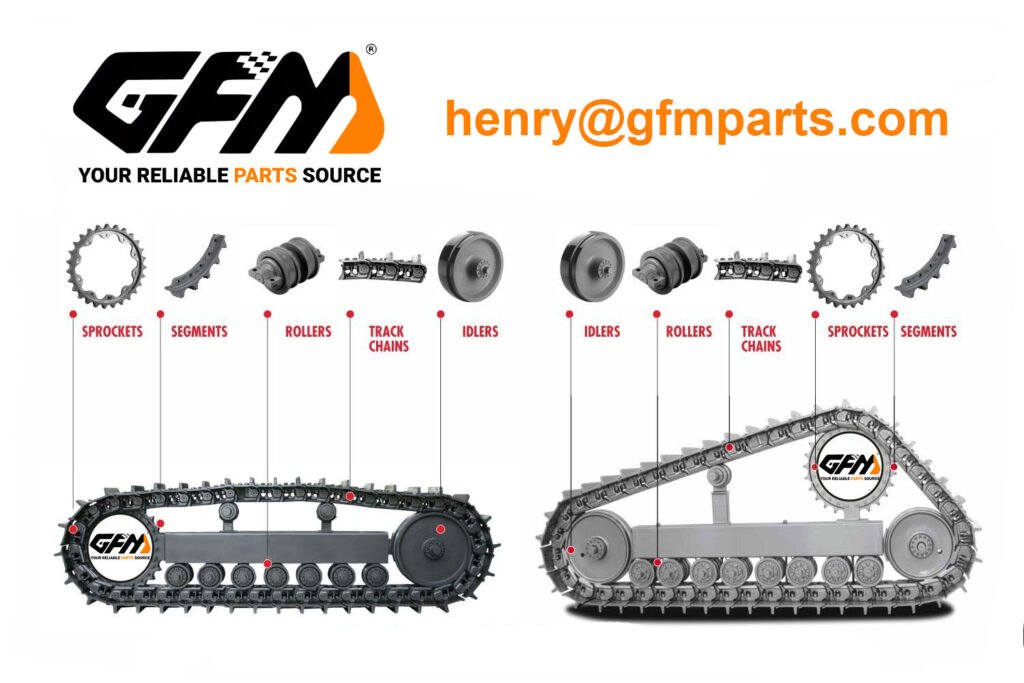

The excavator track assembly is the core part of the excavator’s walking device, and its assembly process directly affects the performance and durability of the equipment.

Assembly process of the excavator track assembly

Prepare tools and parts

- Tools: hydraulic jack, torque wrench, bolt tool, lubricating oil, wire rope.

- Parts: гусеничная цепь, опорный ролик, track idler, track roller, tensioner and track pin.

Inspect track assembly

- Before assembly, check all parts in detail, including whether the track chain has cracks, whether the drive wheel teeth are worn, and whether the guide wheel is flexible.

- Make sure there is no oil or impurities on the surface of the parts, and clean them with detergent if necessary.

Install the carrier roller and track idler

- When installing the drive wheel, make sure that the bolts are tightened to the specified torque value, and at the same time confirm whether the installation position of the drive wheel and the track frame is correct.

- When installing the guide wheel, adjust its horizontal position to avoid excessive friction with the track chain.

Assembling the track rollers

- Install the rollers one by one according to the guide rail position of the track frame to ensure that they are stable and without shaking.

- Rotate the rollers after installation to check whether they can rotate smoothly.

Connecting the track chain

- Lay the track chain flat on the ground and lift one side of the excavator with a wire rope or hydraulic jack.

- Starting from the drive wheel, fix one end of the track chain and gradually pass it around the rollers and guide wheels to ensure that the track chain fits tightly with the gear teeth.

- Use the track pin to connect the two ends of the chain tightly, and use a hammer tool to drive the pin in to ensure that the pin holes are aligned and not loose.

Adjust the tensioner

- When adjusting the tensioner, slowly release the hydraulic oil to achieve a moderate tension of the track.

- Test the tightness of the track chain to ensure that the vertical droop meets the equipment specifications.

Tips for assembling the track chain of an excavator

Ensure symmetrical installation

- During the installation of the track chain, it is necessary to ensure that the tension of the chains on the left and right sides is consistent to prevent deviation or tilt.

Lubrication and rust prevention

- Apply high-quality lubricating oil to the chain pin connection, drive wheel tooth surface and other easily worn parts.

- When working in rainy or high humidity environments, use anti-rust spray appropriately.

Follow the installation sequence

- Complete the installation step by step in the order of “drive wheel-roller-guide wheel-chain connection” to avoid improper installation caused by disorder.

With the help of mechanical tools

- When the crawler chain is connected, hydraulic auxiliary tools can be used to improve operating efficiency and reduce manual operation errors.

Causes of excavator track chain derailment

Track chain is too loose or too tight

- A loose crawler chain will detach from the guide rail during operation, especially when working on uneven terrain.

- A too tight chain will increase the running resistance and even break the crawler pin.

Complex construction environment

- In muddy, sandy or high water content environments, foreign objects may get stuck in the crawler chain, causing the risk of derailment.

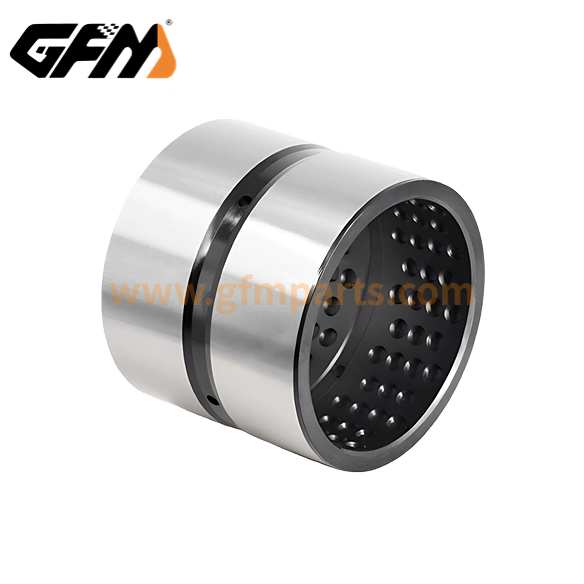

Severe wear of components

- Severe wear of the drive wheel teeth, track bearings or track pins will reduce the stability of the track chain.

Improper installation or maintenance

- Misalignment of the track chain or incomplete fixation of the track pins are important causes of derailment.

- Lack of regular inspection and lubrication maintenance increases the possibility of derailment.

What to pay attention to in daily life

Check the track condition daily

- Focus on checking the tension of the chain, whether the pin hole is loose, and whether the drive wheel and chain are aligned.

- If any abnormality is found, it should be repaired in time to avoid failure during construction.

Cleaning the track system

- After each operation, use a water gun or other tools to clean the soil, sand and other foreign objects in the track.

Lubrication and protection

- Regularly add lubricating oil to the track chain and each axle every week.

- Use appropriate protective covers to prevent splashing mud and water from eroding the track.

Избегайте перегрузки при работе

- Long-term operation under extreme working conditions, such as sharp rocks or deep muddy terrain, will accelerate the wear of the track.

- When encountering complex terrain, slow down and adjust the track tension appropriately.

Regular and comprehensive maintenance

- Perform a comprehensive overhaul every quarter, including replacing severely worn parts, checking the tensioner and hydraulic system.

- Record the use of the track and establish a regular maintenance file.

The assembly and maintenance of the excavator track assembly is a job that requires carefulness and professional skills. By following the correct assembly steps, mastering the assembly skills of the track chain, and combining daily inspections and preventive measures, you can ensure the long-term and efficient operation of the equipment. If you have any technical questions or need to replace high-quality track parts, please feel free to contact our GFM professional производитель деталей ходовой части экскаватора team. We are committed to providing you with the best solutions and services.

| Получите быструю бесплатную расценку | Электронная почта: henry@gfmparts.com | Вотсап: +86 17705953659 |