Among the many key components of an excavator, the track idler plays a vital role. A good track idler not only ensures the smooth operation of the excavator during operation, but is also directly related to the life and safety of the equipment.

Tool and material preparation

Before starting to replace the track idler, make sure that all necessary tools and materials are ready to avoid safety accidents caused by insufficient tools during operation. Common tools and materials include:

- Wrench and socket wrench: used to remove the bolts or nuts that fix the track idler

- Jack or hydraulic lift: auxiliary lifting equipment to ensure the safety of the replacement operation

- Crowbar and disassembly tools: used when encountering fasteners or jamming

- Protective gloves and safety glasses: to ensure the safety of operators

- Lubricants and cleaning agents: used to clean the axle and mounting surface to ensure smooth installation of the new wheel

- Installation tools: such as hammers, mounting gaskets, etc., to ensure that the installation is tight and stable

Make sure all tools are inspected before use and meet site safety standards.

Detailed steps for replacing the track idler

The following steps describe in detail how to replace the track idler of an excavator safely and efficiently:

Safety preparation and equipment shutdown

- Disconnect the power supply and hydraulic system: Before operation, make sure that the excavator has been completely shut down and the power supply is cut off to avoid accidental startup

- Place safety signs: Set up a warning area and place warning signs in the working area to prevent unauthorized personnel from entering

- Use a jack to stabilize the equipment: Use a jack or hydraulic lift to stabilize the equipment during the replacement process to ensure a smooth operating surface

Remove the old track idler

- Check the fixing device: Observe the connection between the track idler and the axle, which is usually fixed by multiple bolts or fasteners

- Loosen the bolts gradually: Use a wrench to loosen the fixing bolts one by one, paying attention to the order to avoid equipment displacement due to uneven force

- Remove the old wheel assembly: When removing, you can use a crowbar to assist and gently remove the track idler from the axle, taking care to prevent damage to other components

Clean and inspect the axle

- Clean the axle surface: Use a detergent to thoroughly remove the old lubricating oil and dirt on the axle

- Check the axle wear: confirm whether the axle has scratches, wear or deformation, and replace or repair the axle if necessary

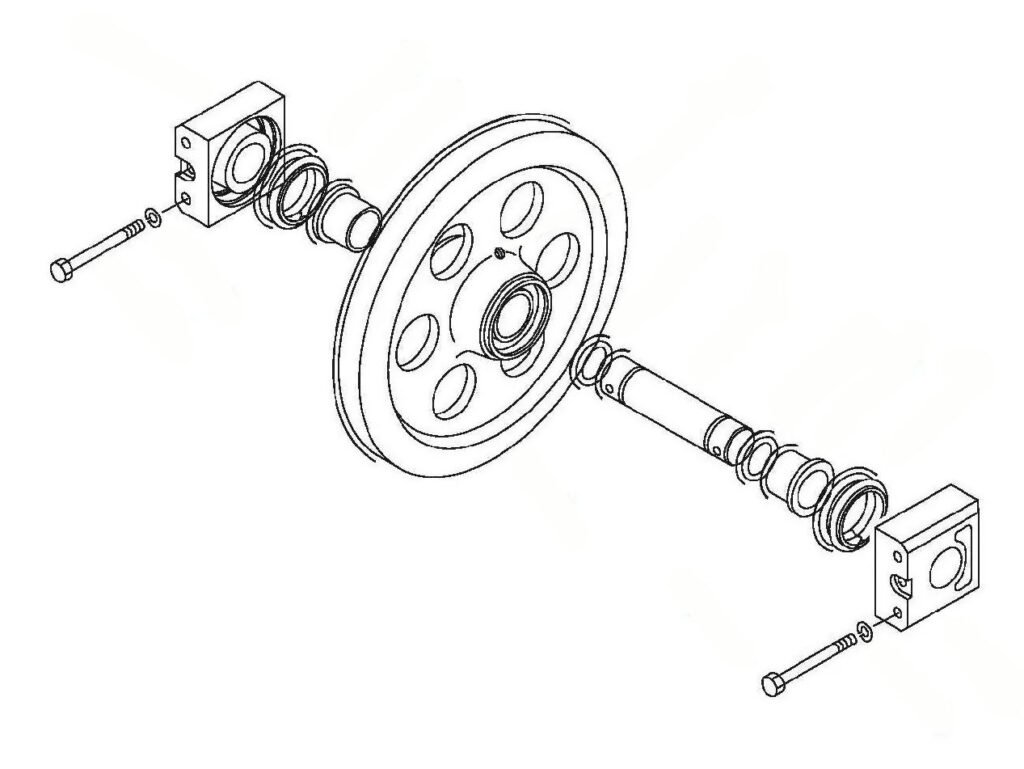

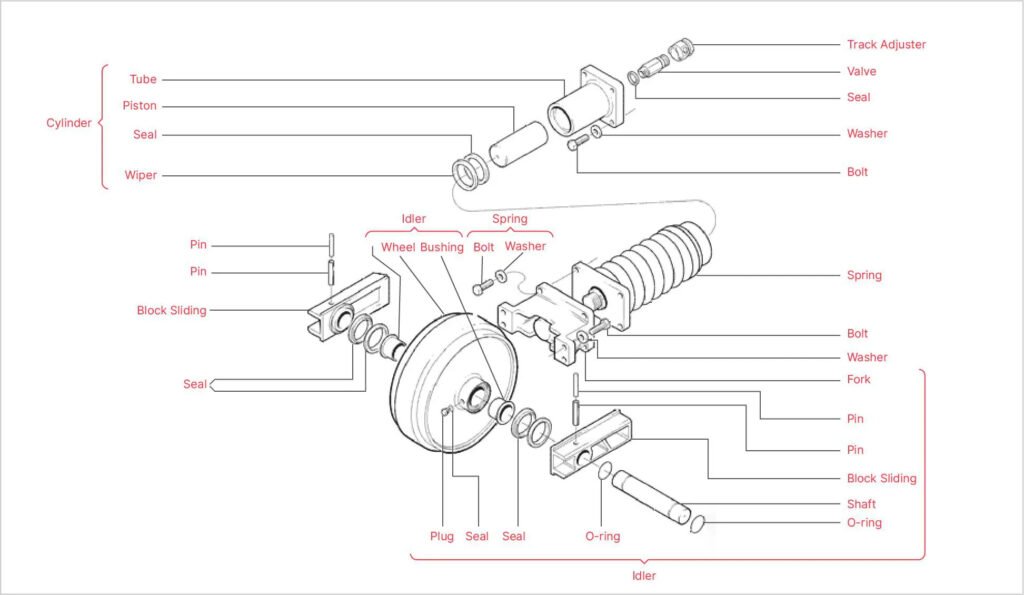

Install the new track idler

- Compare the new and old parts: ensure that the new track idler is consistent with the old part model and specifications

- Place the new track idler: align the new wheel correctly with the axle, and install the gasket or seal to ensure no shaking

- Tighten the bolts: use a wrench to gradually tighten all bolts in the original fixed order, be careful not to overtighten or miss, it is recommended to adjust according to the torque specification

- Смазка: After tightening, add an appropriate amount of lubricating oil to the joints and axle parts to ensure smooth and corrosion-resistant operation in long-term operation

Functional testing and trial operation

- Check the installation stability: reconfirm whether all bolts are firmly fixed to ensure no looseness

- Low-speed trial operation: run the equipment at a low speed to check whether the operating status of the track idler is normal

- Record maintenance data: record the date of replacement, operator and equipment operation status, and provide data support for future routine maintenance

Precautions during replacement

During the process of replacing the track idler, there are several key precautions that can effectively avoid common errors and extend the life of the equipment:

- Strictly follow the equipment manual: Different models of excavators may have slightly different track idler installation methods, so be sure to refer to the manufacturer’s technical manual

- Follow safety regulations: Confirm site safety before operation, use appropriate protective equipment, and avoid falling objects from heights or equipment misstarting

- Use appropriate tools: Do not use damaged or mismatched tools, otherwise it is easy to cause component damage

- Pay attention to lubrication and anti-corrosion treatment: After installation, fully lubricate key components to reduce friction and extend service life

- Регулярный осмотр: Regularly check the track idler status after replacement, and promptly handle possible abnormal situations

Transport track idler and daily maintenance standard operation

In order to ensure the stable operation of the excavator in daily transportation and long-term use, daily maintenance and transportation operations of the track idler are crucial:

Precautions for daily transportation

- Avoid frequent impact: During transportation, try to avoid severe collisions and vibrations to keep the equipment stable

- Check tires and suspension system: Ensure that the track idler and related suspension system are fully inspected before transportation to prevent hidden dangers caused by long-distance transportation

- Appropriate reinforcement: During transportation, temporary reinforcement measures can be taken for the track idler and connected parts to avoid loosening due to bumps

Daily maintenance standard operation

- Регулярная уборка: Clean the track idler and axle surface regularly to remove dust and impurities and keep the working environment clean

- Regular lubrication: Add lubricating oil at regular intervals according to usage to keep the track idler running smoothly

- Regularly check wear: Through regular inspections, timely detect wear and deformation of the axle or track idler to prevent problems before they happen

- Record maintenance log: Establish a detailed maintenance log to record each maintenance and inspection data to provide a basis for subsequent repairs

- Follow the manufacturer’s recommended cycle: Perform daily maintenance according to the maintenance recommendations and maintenance cycles provided by GFM excavator parts manufacturers

| Получите быструю бесплатную расценку | Электронная почта: henry@gfmparts.com | Вотсап: +86 17705953659 |

The replacement and daily maintenance of the гусеничный экскаватор is not only related to the operating efficiency of the equipment, but also an important part of ensuring safe production. Through comprehensive tool preparation, detailed disassembly and installation steps, and strict safety operation specifications, the service life of the excavator can be effectively extended and maintenance costs can be reduced. Both operators and equipment managers should strictly follow the manufacturer’s technical manual and standard maintenance procedures to ensure that every step of the operation meets safety and professional requirements.