Table of contents

Getting to Know GFM – A Reliable Manufacturer of Durable Excavator Parts

As a representative Chinese construction machinery parts enterprise, GFM has rapidly grown since its establishment in 2011 through 14 years of manufacturing experience, modern production lines, strict quality management systems, and near-full compatibility with mainstream brands. It has become widely recognized by global customers as an excavator parts manufacturer and excavator parts supplier.

1. Company Strength and Product Range

GFM operates a highly automated and large-scale production facility equipped with advanced forging equipment, automated machining centers, casting facilities, and full inspection instruments, ensuring strict control throughout the entire process from raw materials to finished parts.

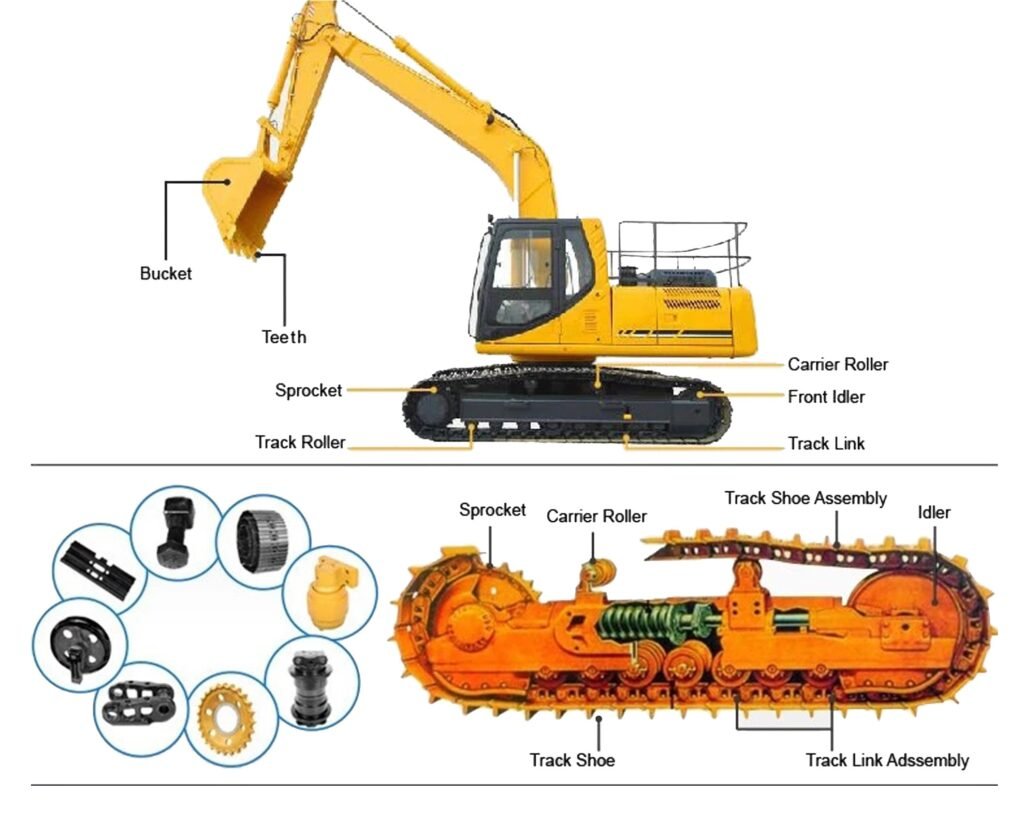

Main products include:

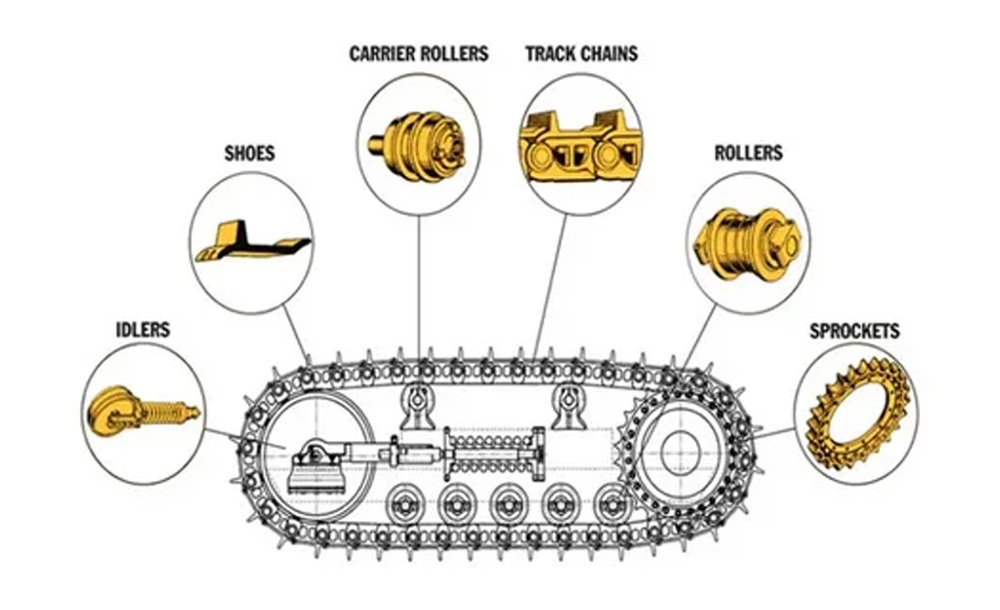

- Chassis parts: bottom rollers, carrier rollers, idlers, sprockets, drive wheels

- Undercarriage components: track chains, track shoes, track assemblies

- Structural and wear parts: buckets, bucket teeth, tooth pins, track pins

- Fasteners and bushings: bolts, nuts, bushings, steel sleeves, etc.

The products meet the high-frequency needs of excavators and bulldozers and are compatible with more than 90% of mainstream global brands and models.

2. Wide Brand Compatibility

GFM parts have strong adaptability and can cover major global construction machinery brands, providing clear advantages in the aftermarket and repair sectors.

Main compatibility scope includes:

- International mainstream brands: Caterpillar, Komatsu, Hitachi, Volvo, Kobelco, Doosan, Hyundai, Kubota, SANY, Liugong, XCMG, Shantui, Yanmar, Bobcat, etc.

- Multi-tonnage matching: suitable for 5-ton mini excavators to 50-ton large mining excavators

- Adaptable to multiple working conditions: mining, wetlands, demolition, road construction, earthwork, with corresponding material and heat-treatment solutions

This wide compatibility enables GFM to perform strongly in global construction sites, repair markets, and bulk procurement environments.

3. High-Standard Manufacturing Process

GFM strictly follows industrial-grade standards in its manufacturing process, maintaining high requirements from material selection to final inspection:

- Use of high-strength alloy steel raw materials

- Casting or forging processes to ensure structural strength

- Complete precision heat treatment (quenching + tempering)

- Strict hardness testing, metallographic analysis, and life-cycle testing

- 100% inspection of critical dimensions

These processes ensure the products maintain excellent durability under heavy load, strong impact, and high-wear working environments.

4. Product Advantages and After-Sales Support

GFM is well-known in the global supply chain system for high efficiency and cost-effectiveness:

- ≥1 year or 2000 hours warranty

- 1000+ models available in stock for fast delivery

- 100% factory-direct pricing with excellent cost performance

- Supports bulk orders and custom projects

- Global shipping covering Southeast Asia, the Middle East, Europe, Africa, and more

With stable quality, fast response, and comprehensive after-sales support, GFM is becoming one of the most competitive Chinese suppliers in the international market.

Introduction to Top 5 Excavator Parts Manufacturers in the World

Caterpillar (CAT) – Industry-Leading Global Excavator Parts Manufacturer

Caterpillar (CAT) is one of the most influential giants in the global construction machinery industry. Since its establishment in 1925, its equipment and parts have been widely used in more than 190 countries around the world. As an industry-leading excavator parts manufacturer, CAT has an extremely broad product system that almost covers all key components required for the operation of excavators, including:

- Chassis system: bottom rollers, sprockets, idlers, track chains

- Hydraulic system components: hydraulic pumps, hydraulic valves, hydraulic cylinders

- Power system components: engine parts, transmission system parts

- Work equipment components: buckets, links, pins, bushings

- High-performance wear parts: CAT self-developed alloy steel, etc.

According to the Caterpillar annual report, CAT invests about USD 2 billion each year in R&D and technology upgrades, with a large portion dedicated to material science, heat-treatment technology, and automated machining technology. This ensures its parts always maintain industry-leading performance in service life, stability, safety, and compatibility.

CAT has also built a global supply network with more than 160 spare parts service centers, ensuring users can obtain original parts quickly in any region of the world, significantly reducing downtime and improving construction efficiency. This is one of the main reasons CAT continues to dominate the global excavator parts market.

Komatsu – The Symbol of Japanese Precision Manufacturing

Komatsu is Japan’s largest construction machinery manufacturer and the world’s third-largest equipment giant. It is renowned worldwide for precision manufacturing, high reliability, and long service life. Its parts are especially notable in mining equipment and high-performance excavators.

Main advantages include:

- Leading metallurgical technology

- High-precision CNC machining equipment

- Komtrax intelligent monitoring system

- Comprehensive global after-sales and warehousing network

Komatsu undercarriage parts, hydraulic components, and structural parts are known for long life and stable quality, making them a preferred choice for large engineering contractors.

Hitachi Construction Machinery – Known for Durability and Stability

Hitachi Construction Machinery is well known for “stability, safety, and energy efficiency,” and is especially renowned for its hydraulic system technology. Its hydraulic components, undercarriage parts, and electronic control components offer outstanding precision and service life.

Advantages include:

- Industry-leading hydraulic system technology

- Low failure rate and long lifespan

- ISO-certified high-standard quality system

- Hitachi parts are widely used in projects requiring high stability and continuous operation.

Volvo Construction Equipment – A European Brand Focused on Safety and Innovation

Volvo Construction Equipment is known for safety, advanced technology, and environmental performance. Its parts cover engine systems, hydraulic systems, undercarriage parts, and electronic control systems, featuring durability, efficiency, and precision.

Main advantages:

- Strict EU environmental and safety standards

- Strong global service support system

- Long part lifespan and high fuel efficiency

- Volvo parts are ideal for long-term, large-scale engineering projects where equipment reliability is critical.

Doosan — A Leading Name in South Korean Construction Machinery

Doosan is a leading construction machinery manufacturer in South Korea and one of the world’s renowned producers of excavators and heavy equipment. Known for high performance, durability, and technological innovation, its parts excel in construction sites, mining operations, and other high-demand working environments.

Key Advantages Include:

- Advanced hydraulic system design and manufacturing technology

- Precision casting and application of high-strength materials

- DX intelligent monitoring system for remote management and predictive maintenance

- Comprehensive global sales and after-sales service network with fast spare parts supply

Doosan’s undercarriage components, hydraulic systems, and critical structural parts are well-known for their wear resistance, long service life, and reliability. They are highly preferred by contractors and equipment rental companies, especially for projects requiring heavy-duty, continuous operation.

How to Choose the Right Excavator Parts Manufacturer

Choosing a reliable excavator parts manufacturer globally not only affects equipment stability but also determines long-term operating costs. The following four key aspects help companies quickly identify trustworthy suppliers.

- Whether the technical capability and production strength are solid: Whether the manufacturer has advanced production equipment, automated production lines, large-scale processing capacity, and mature heat-treatment processes is essential for part durability and consistency. Excellent manufacturers often disclose factory size, equipment quantity, key processes, and R&D investment for customer evaluation.

- Whether certifications, testing, and quality control systems are complete: Reliable suppliers must have strict QC systems such as ISO9001, material testing, hardness testing, dimensional accuracy inspection, and wear-resistance testing, ensuring consistent performance in every batch and reducing maintenance risks.

- Whether product compatibility and customization capabilities meet requirements: Different working environments require different materials, hardness, heat treatment, and structural designs. Outstanding manufacturers should provide drawing customization, sample development, and non-standard design services, and recommend appropriate materials or processes based on working conditions.

- Whether delivery capability, inventory system, and after-sales service are reliable: Stable delivery time, available stock, and a global logistics network are crucial to project progress. Reliable suppliers also provide assembly guidance, technical support, and quick issue response to assist users anytime.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Caterpillar, GFM, Komatsu, Hitachi, and Volvo—five leading excavator parts manufacturers globally—have become the industry backbone with advanced technology, strict quality systems, and reliable performance. Among them, GFM, as a representative of Chinese manufacturing, continues to gain trust worldwide with 14 years of experience, broad compatibility, strict quality control, and high cost-effectiveness.

Whether you are a contractor, equipment dealer, repair service provider, or rental company, choosing the right excavator parts manufacturer or excavator parts supplier helps reduce maintenance costs, extend equipment life, and significantly improve project efficiency. This guide aims to provide professional and practical insight for your procurement decisions.