Durable Excavator Undercarriage Parts by GFM for Leading Brands

- Company Overview: Established in 2011, Quanzhou Ganfeng Machinery Co., Ltd. (GFM) specializes in excavator parts manufacturing, focusing on undercarriage components for excavators and bulldozers.

- Experience and Track Record:

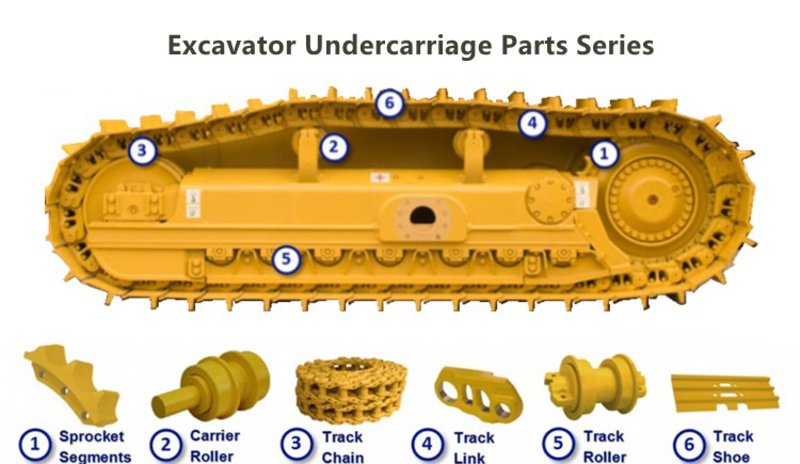

With 14 years of industry experience, GFM has built a mature production system and strong reputation among domestic and international clients. - Core Undercarriage Products:GFM produces pin and bushings, lock pins, track chains, sprockets, idlers, carrier rollers, track rollers, and track shoes.

- Brand Compatibility: Products are compatible with major brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Doosan, Hyundai, Kubota, Bobcat, Yanmar, Sany, Liugong, XCMG, and Shantui.

- Quality Assurance:Every component undergoes rigorous hardness, tensile, impact, and fatigue tests, meeting high durability and reliability standards.

- Global Client Base: GFM exports products worldwide and serves clients in construction, mining, and infrastructure projects.

- Performance and Recognition: With advanced technology, strict quality control, ample inventory, and competitive pricing, GFM undercarriage parts are recognized globally for their reliability and performance.

Top 5 Excavator Undercarriage Parts Manufacturers in Asia

XCMG (China): OEM Undercarriage Manufacturing at Industrial Scale

- OEM Background: XCMG (Xuzhou Construction Machinery Group) is one of Asia’s largest construction machinery OEMs, manufacturing excavators and key undercarriage components within its own industrial system.

- Integrated Undercarriage Production: XCMG produces track chains, track rollers, carrier rollers, idlers, sprockets, and complete undercarriage assemblies designed specifically for its excavator models.

- Large-Scale Manufacturing Capability: With large production bases in China, XCMG operates high-volume automated lines that support both domestic demand and global equipment exports.

- Engineering and Process Control: Undercarriage components are manufactured using CNC machining, controlled heat treatment, and standardized welding processes to ensure structural strength and dimensional accuracy.

- OEM Compatibility Advantage: Because undercarriage parts are developed together with complete machines, load distribution, wear balance, and service life are optimized at the design stage.

- Quality and Testing Standards: XCMG applies OEM-level testing, including hardness, fatigue, and impact resistance checks, ensuring stable performance under heavy-duty working conditions.

- Global Equipment Deployment: XCMG excavators equipped with original undercarriage systems are widely used in infrastructure, mining, and earthmoving projects across Asia, the Middle East, Africa, and South America.

- OEM Reliability Positioning: As a vertically integrated excavator parts manufacturer, XCMG offers predictable quality, consistent supply, and long-term reliability expected from a leading OEM brand.

Hitachi Construction Machinery (Japan): OEM Undercarriage Engineering Excellence

- OEM Background: Hitachi Construction Machinery is one of Japan’s leading excavator OEMs, with in-house manufacturing of critical undercarriage components for its own machines.

- Undercarriage Product Scope: Hitachi produces OEM-grade track chains, sprockets, idlers, carrier rollers, and track rollers designed specifically for Hitachi excavators.

- Engineering Standards: All undercarriage parts follow strict Japanese industrial standards, focusing on dimensional accuracy, fatigue resistance, and long service life.

- Integrated Machine Design: Because undercarriage parts are developed together with complete machines, compatibility and load distribution are optimized at the design stage.

- Global Supply Network: Hitachi maintains manufacturing bases and parts distribution centers across Asia, ensuring stable supply for both new equipment and replacement demand.

SANY Heavy Industry (China): Large-Scale OEM Manufacturing Power

- OEM Manufacturing Scale: SANY is one of Asia’s largest construction machinery OEMs, with vertically integrated production covering excavators and undercarriage systems.

- Core Undercarriage Components: SANY manufactures track chains, rollers, idlers, sprockets, and complete track assemblies for its excavator product lines.

- Advanced Production Technology: The company applies automated welding, CNC machining, and controlled heat treatment to ensure consistent quality at high output volumes.

- Standardization and Cost Control: OEM-scale production allows SANY to balance durability and cost efficiency, making its undercarriage parts competitive in large construction projects.

- Global Market Presence: SANY excavators and genuine undercarriage parts are widely used across Asia, the Middle East, Africa, and Europe.

Komatsu (Japan): Original Equipment Reliability

- Integration of Machines and Parts: Komatsu produces both machines and original parts, ensuring perfect compatibility and performance stability.

- Strict Quality Standards: Undercarriage components undergo high-load cycles, corrosion testing, and high-temperature operations, with each batch certified by headquarters.

- Core Products: Komatsu’s products include track chains, drive wheels, idlers, and tensioning systems, offering superior durability compared to non-OEM alternatives.

- After-Sales and Service Network: Komatsu maintains extensive service points across Asia, providing parts, installation, and maintenance support.

Doosan (South Korea): Local Manufacturing with International Expansion

- Development and Local Production: Doosan has established manufacturing and distribution networks in China and Southeast Asia, supporting localized production and delivery.

- Core Products and R&D: Main products include carrier rollers, track chains, drive wheels, and idlers. Advanced alloy steel and surface treatment enhance wear and impact resistance.

- Client Base: Doosan supplies both its own machines and third-party OEM clients, widely used in construction, ports, and mining.

- Market Impact: Known for reliability and cost-effectiveness, Doosan products are expanding from mid-tier Asian markets to global markets.

Practical Buyer’s Guide for Choosing an Excavator Undercarriage Parts Manufacturer

- Quality Certification: Prioritize suppliers with ISO9001, ISO14001, or other international certifications for traceable and standardized production.

- Manufacturing Process: Check heat treatment, CNC machining, and surface treatment technology to ensure durability and fit.

- Delivery Speed: Factories or warehouses located in Asia offer faster delivery and localized service.

- After-Sales Service: Ensure professional installation guidance, training, and rapid spare part supply.

- OEM vs. Third-Party Manufacturers: OEM parts offer superior compatibility and lifespan; third-party parts provide cost-effectiveness and supply flexibility.

- Practical Tips: Request sample testing before bulk purchase, confirm delivery schedules and warranty terms, and consider annual framework agreements for long-term supply stability.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

GFM, Berco, ITM, Komatsu, and Doosan represent Asia’s top Excavator Undercarriage Parts Manufacturers, each excelling in precision manufacturing, international quality standards, localized service, original equipment compatibility, and technological innovation. By carefully considering quality certification, production capability, delivery speed, and after-sales support, buyers can select the optimal excavator parts manufacturer to ensure reliability, cost efficiency, and long-term performance.