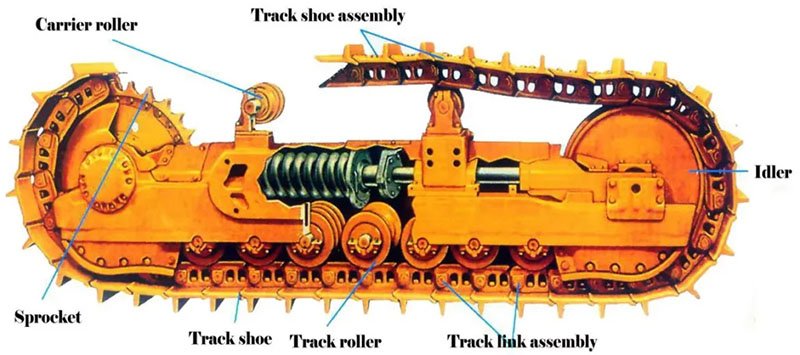

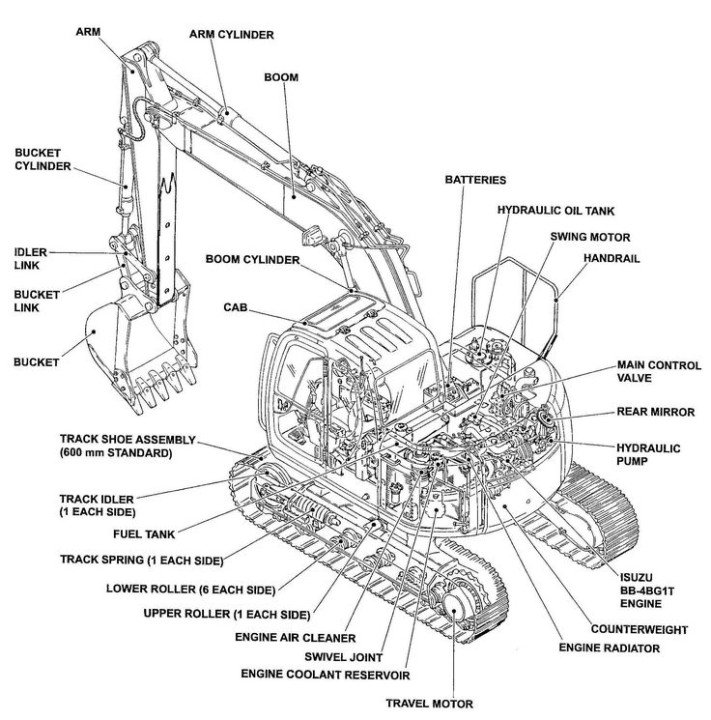

Ekskavatörler ve buldozerler yaygın inşaat makineleridir ve palet makaraları bu makinelerin temel bileşenleridir. Palet makarası, paletin normal çalışmasını yönlendirmek, palet gerginliğini korumak ve zeminle dengeli temas sağlamak için kullanılan palet sisteminin bir parçasıdır.

Ekskavatörün paletli kasnağı ile buldozerin paletli kasnağı arasındaki temel fark

Hem ekskavatörler hem de buldozerler paletli makaralarla donatılmış olsa da, bu iki makinenin paletli makaraları arasında bazı önemli farklılıklar vardır:

Yapısal tasarım ve kuvvet ortamındaki farklılıklar

- Genellikle tek flanşlı veya çift flanşlı yapı tercih edilir, bu yapının sık dönüş ve tırmanışlarda oluşacak yanal darbelere dayanıklı olması gerekir.

- Ekskavatörün çalışma sırasında birden fazla açıda dönmesi gerektiğinden, palet makarası ile paletin birbirine geçme sıklığı daha yüksektir ve asimetrik aşınma meydana gelmeye eğilimlidir.

- Çoğu, doğrusal buldozer operasyonlarının stabilitesini vurgulayan geniş çift flanşlı bir yapı olarak tasarlanmıştır ve esas olarak uzunlamasına basınç taşırlar.

- Buldozerin paletli kasnak malzemesi daha çok basınç dayanımına odaklanırken, ekskavatörün paletli kasnağı daha çok darbe tokluğuna ihtiyaç duyar.

İşlevsel farklılıklar

- Ekskavatörün paletli kasnağı, esas olarak paletli aracın düzgün çalışmasını sağlamak ve virajlarda paletli aracın yönlendirilmesine yardımcı olmak için kullanılır. Ekskavatörün çeşitli karmaşık arazilerde çalışması gerektiğinden, paletli kasnağı genellikle daha hassas ve karmaşık bir yapıya sahip olacak şekilde tasarlanır.

- Buldozerin paletli kasnağı genellikle daha basittir ve temel işlevi, buldozer çalışırken paletli kasnağın daha yüksek basınca dayanabilmesini sağlamak için paletli kasnağın gerginliğini korumaktır. Buldozer nispeten düz bir zeminde çalıştığı için, buldozerin paletli kasnağı çoğunlukla tek ve güçlü bir destektir.

Malzeme ve proses gereksinimleri

- Ekskavatörün paletli dingilinde genellikle ZG35Mn veya 42CrMo alaşımlı çelik kullanılır ve aşınma direnci söndürme ve temperleme + yüzey söndürme ile iyileştirilir.

- Buldozerin paletli kasnağı genellikle yüksek karbonlu çelikten dökülür ve yüzeyi kum ve çakıl aşınmasına dayanacak şekilde karbürlenir.

Çalışma koşullarının neden olduğu aşınma farklılıkları

- Ekskavatörler genellikle karmaşık arazilerde (madenler ve inşaat sahaları gibi) bulunur ve paletli makaralar çakıl ve çamurun girmesine karşı hassastır ve bu da conta bozulmasına neden olur.

- Buldozerler çoğunlukla düz zeminlerde çalışırlar ve yüksek sıcaklık nedeniyle kum aşınması ve yağ bozulmasıyla karşı karşıya kalırlar.

Palet gergi makaralarının olası sorunları ve nedenleri

Palet makaraları normal çalışma sırasında hayati bir rol oynasa da, sık kullanım ve çevresel faktörler nedeniyle bazı yaygın sorunlara da yol açabilir. İşte bazı yaygın sorunlar ve olası nedenleri:

Çok hızlı aşınıyor

- Fenomen: Jantın kalınlığının eşit olmaması, diş yüzeyinde çukurlar veya soyulmalar oluşması, bunun sonucunda paletin dengesiz çalışması.

- Neden analizi:

- Düşük palet gerilimi kaymaya ve sürtünmeye neden olur.

- Çalışma zeminindeki sert parçacıklar (çakıl gibi) palet ile palet makarası arasına gömülerek aşındırıcı aşınmaya neden olur.

- Ray ofsetinin zamanında ayarlanamaması tek taraflı kuvvet aşırı yüklenmesine neden olur.

Palet gergisi eğimi veya deformasyonu

- Fenomen: Eğilme veya deformasyon meydana gelir.

- Neden analizi:

- Genellikle uzun süreli bakım eksikliğinden dolayı iç parçalar aşınır veya hasar görür ya da palet üzerindeki dengesiz yük, palet gergi kasnağında dengesiz kuvvet oluşmasına neden olur.

Yatak sıkışmış veya anormal ses

- Fenomen: Arttırılmış dönme direnci ve metal sürtünme sesi.

- Neden:

- Conta halkasının eskimesi çamurlu su sızmasına ve gres kirlenmesine yol açar.

- Uzun süreli aşırı yük çalışması, rulman yuvarlanma yolunda çukurlaşmaya neden olur.

Tekerlek gövdesi kırığı

- Fenomen: Jant çatlakları ve göbek kırıkları.

- Neden:

- Malzeme kusurları (döküm gözenekleri, uygun olmayan ısıl işlem gibi).

- Aşırı yüklenme etkisi (yüksekten düşme veya sert bir cisme çarpma gibi).

Ray düşüyor veya dengesiz

- Fenomen: Ray düşüyor veya dengesiz bir şekilde ilerliyor.

- Neden:

- Bu durum, palet gergi makarasının aşırı aşınması veya yanlış montajından kaynaklanabilir ve bu da paletin stabil bir şekilde çalışmasını engelleyerek iş verimliliğini etkiler.

Palet gergisi sorunlarıyla nasıl başa çıkılır?

Palet gergi kasnağıyla ilgili bir sorun tespit edildiğinde, sorunun daha da kötüleşmesini önlemek için zamanında müdahale etmek çok önemlidir. İşte yaygın sorunlardan bazıları:

Aşınma onarım teknolojisi

- Hafif aşınma: Jantın yüzeyini kaynak yaparak onarmak için aşınmaya dayanıklı kaynak çubukları (örneğin D256) kullanın ve işlemden sonra boyutunu eski haline getirin.

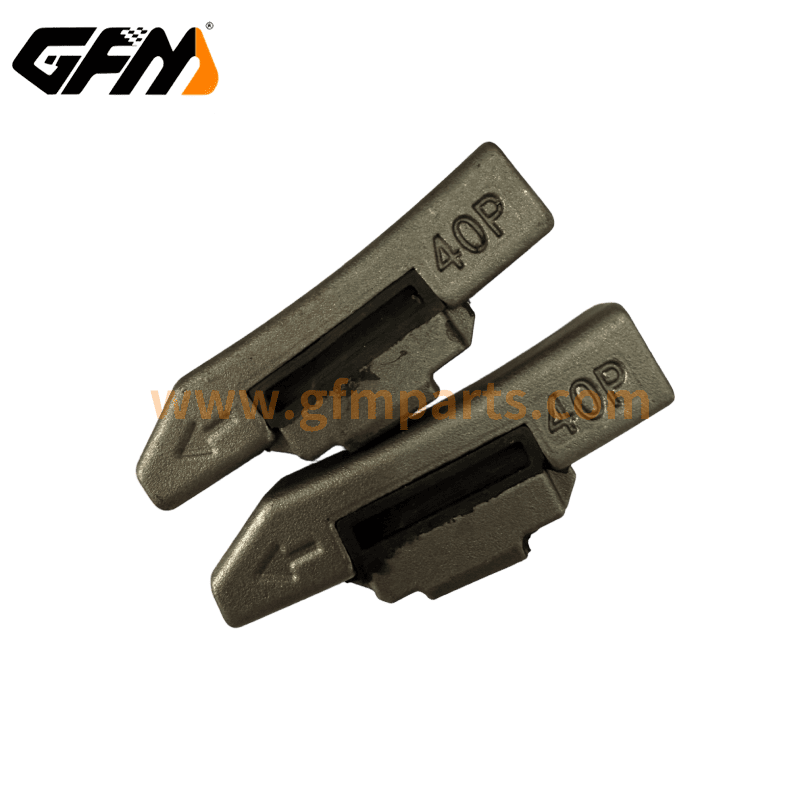

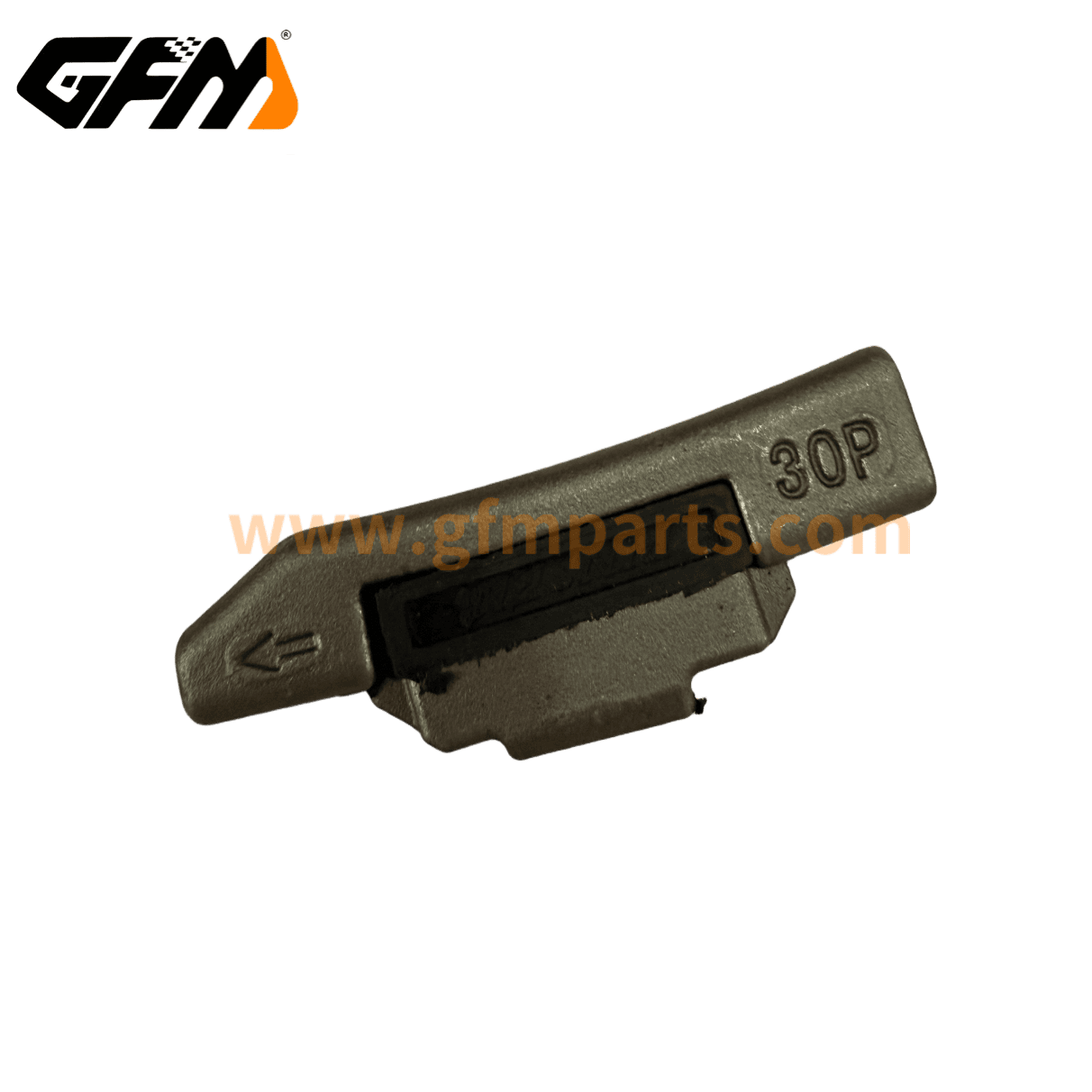

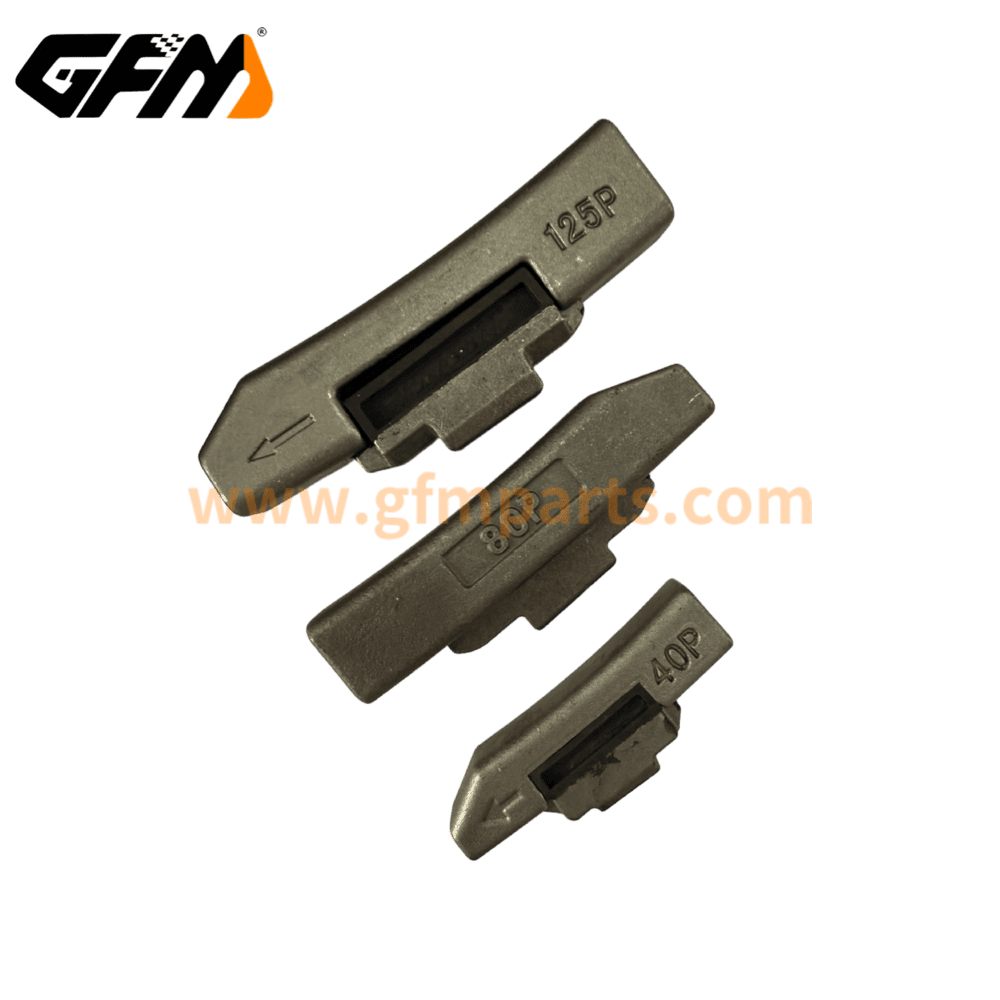

- Aşırı aşınma: Palet gergi kasnağını ekipman modeline uyacak şekilde değiştirin (örneğin Komatsu PC200-8 özel bir palet gergi kasnağı gerektirir).

Rulman bakım süreci

- Palet gergisini çıkarın ve eski gresi temizleyin.

- Rulman yatağını kontrol edin. Çukurlaşma meydana gelirse, SKF/NSK marka rulmanı değiştirin.

- Lityum bazlı gresle (NLGI sınıfı 2) doldurun ve contayı çift dudaklı iskelet yağ contasıyla değiştirin.

Tekerlek gövdesi kırığının acil tedavisi

- Pistin molozla hasar görmesini önlemek için işlemi derhal durdurun.

- Hızlı transfer için GFM teknik desteğiyle iletişime geçin ve ekipman seri numarasını sağlayın.

Palet gergisinde sorun yaşanmaması için günlük bakım nasıl yapılmalıdır?

Paletli gergi kasnağıyla ilgili sorunları önlemek için günlük bakım özellikle önemlidir. İşte bazı öneriler:

Düzenli denetim

Palet gergisini ve yataklar, palet gerginliği vb. gibi diğer ilgili bileşenleri düzenli olarak kontrol ederek normal çalışma koşullarında olduklarından emin olun.

Yağlanmış halde tutun

Sürtünme kaybını azaltmak ve hizmet ömrünü uzatmak için palet gergi rulmanlarını ve diğer bileşenleri düzenli olarak uygun yağlayıcılarla doldurun.

Aşırı yük işletiminden kaçının

Ekskavatör veya buldozer kullanırken, özellikle engebeli veya sert zeminlerde, paletli kasnağın aşırı yük nedeniyle hasar görmesini önlemek için aşırı yüklemeden kaçınmaya çalışın.

Temizlik ve bakım

Her işlemden sonra makine üzerindeki çamur ve kumu temizleyerek, döküntülerin palet gergi sistemine girmesini ve sürtünme ve aşınmaya neden olmasını önleyin.

Ray gerginliğini kontrol edin

Palet gerginliğini önerilen aralıkta tutun; aşırı veya yetersiz gerginlik, palet gergi makarasının aşırı aşınmasına neden olur.

| Hızlı ve ücretsiz bir teklif alın | E-posta: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Paletli istifleyici, ekskavatör ve buldozer palet sistemlerinin vazgeçilmez bir parçasıdır. Düzenli kontroller, sorunların zamanında giderilmesi ve bilimsel günlük bakım, paletli istifleyicinin normal çalışmasını sağlamanın ve hizmet ömrünü uzatmanın anahtarıdır. Yaygın sorunların nedenlerini ve bunlarla nasıl başa çıkılacağını anlayarak, ekipman arızalarını etkili bir şekilde azaltabilir, iş verimliliğini artırabilir ve bakım maliyetlerini düşürebilirsiniz.