What is a PPR track chain?

Bulldozer PPR track link (Positive Pin Retention Track Link) is a high-strength track component designed for heavy bulldozers. It uses an advanced positive pin retention system to provide higher durability, wear resistance and better load distribution. PPR track link performs well in extreme working environments, especially for high-load, high-strength earthworks, construction and mining.

Structural characteristics of PPR track link

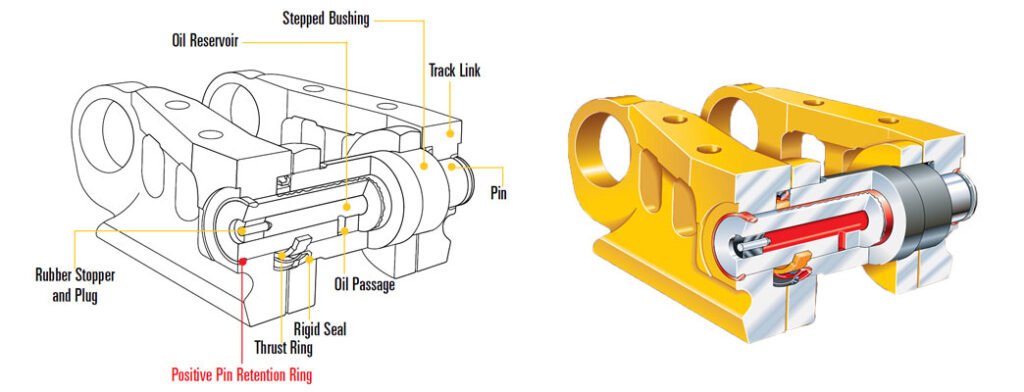

Positive pin retention system

The core feature of PPR track chain is its positive pin retention system. The positive pin retention the chain pins to the track shoe in a special way, ensuring the stability and durability of the chain. During long-term and high-intensity use, the positive pin retention effectively prevents wear between the pins and the chain plate, extending the service life of the chain.

High-strength steel

The PPR track chain is made of high-strength alloy steel to ensure that it has sufficient tensile and compressive resistance. It can withstand the huge impact force from the bulldozer body, soil and rock, and adapt to various harsh construction environments.

Wear-resistant design

The surface of the track chain undergoes a special heat treatment process to improve its wear resistance and corrosion resistance. Even in extremely wet or muddy working environments, PPR track chains can maintain a long service life.

Flexibility and load distribution optimization

The PPR track chain adopts a flexible chain design, which can effectively disperse and transfer the load of the vehicle, reduce local wear of the track system, and ensure the stability and efficient operation of the bulldozer on uneven terrain.

Design principle of PPR track chain

The design principle of PPR track chain is based on the following key factors:

Efficient load distribution: Each link of the chain is accurately calculated to ensure that the load can be evenly distributed to the entire track system. The positive pin retention reduces local wear by optimizing the contact surface between the chain and the track shoe, thereby improving the stability and service life of the system.

Structural reinforcement: The design uses thickened track shoe and stronger pins to improve the overall load-bearing capacity by strengthening the various connection parts of the chain. This design enables the PPR track chain to maintain stable operation when dealing with high-intensity construction environments.

Earthquake resistance: During the operation of the bulldozer, the track chain will be subjected to a certain impact force due to uneven ground. The PPR track chain adopts a design with strong earthquake resistance, which effectively reduces the damage to the chain caused by impact force and extends the service life.

Advantages of PPR track chain

Longer service life

The design of the positive pin retention can effectively reduce the wear of the track chain and greatly extend the service life of the product. Even under high-intensity and high-frequency operations, the PPR track chain can still maintain a low maintenance frequency and less replacement cost.

Higher work efficiency

Due to the wear resistance and high load bearing capacity of the PPR track chain, the bulldozer can work in more harsh environments. This improves the adaptability of the bulldozer in complex construction sites, thereby improving work efficiency.

Improved stability of the bulldozer

The optimized load distribution and earthquake-resistant design make the bulldozer more stable during operation. In complex construction environments, PPR track chains can help bulldozers maintain good traction and ensure stability and safety during construction.

Low maintenance cost

Because the design of PPR track chains effectively reduces wear, the maintenance cycle of bulldozers is relatively long. Long-term use does not require frequent chain replacement or repair, thereby reducing overall maintenance costs.

Strong adaptability

PPR track chains can adapt to various complex terrains and harsh working conditions, including sand, mud, rugged terrain, etc. Whether it is a flat construction site or a difficult mountain, PPR track chains can provide excellent support.

Application scenarios of PPR track chains

Bulldozer PPR track chains are widely used in the following fields:

Earthwork

In earthwork, bulldozers need to work for a long time in soft or hard soil. PPR track chains can provide stronger traction and stability to ensure that bulldozers can efficiently complete earthwork operations.

Construction

During construction, bulldozers often need to travel through different types of terrain. PPR track chains are highly adaptable and can easily cope with complex environments on construction sites, helping bulldozers to complete tasks smoothly.

Mining

In the mining industry, bulldozers need to face harsh operating conditions, such as rocks, heavy soil, etc. The wear resistance and shock resistance of PPR track chains make them an ideal choice.

Agricultural operations

In some large-scale farmland operations, bulldozers need to cross soft or muddy ground. The superior performance of PPR track chains helps bulldozers to successfully complete tasks such as plowing and leveling.

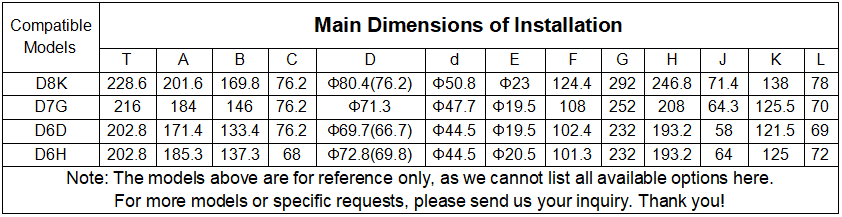

GFM Bulldozer PPR track Chain

As a leading bulldozer track chain manufacturer, GFM is committed to providing customers with high-quality PPR track chains. We use high-quality alloy steel and strictly control every link in the production process to ensure that each PPR track chain has superior durability and high efficiency.

GFM’s PPR track chain not only meets industry standards, but also provides customized services to meet the personalized needs of different customers. Whether it is high-intensity mining operations or complex construction sites, GFM’s PPR track chain can provide reliable support, helping customers improve operating efficiency and reduce maintenance costs.

| Hızlı ve ücretsiz bir teklif alın | E-posta: henry@gfmparts.com | Whatsapp: +86 17705953659 |

As an important part of the bulldozer track system, bulldozer PPR track chain has unparalleled advantages. Its excellent structural design and durability enable it to provide efficient and stable support in various harsh environments. If you are looking for a high-performance and high-reliability crawler chain, GFM’s PPR track chain will be your best choice.

Through continuous optimization and innovation, we are committed to providing customers with more high-quality, customized track chain products to help your equipment maximize its effectiveness in various application scenarios.