When it comes to the efficient functioning of excavators, sprockets and segments play a vital role in the performance and durability of the machine. As a leading excavator sprocket manufacturer, GFM takes pride in providing high-quality sprockets and segments that ensure your machinery operates at its peak.

What Are Excavator Sprockets and Segments?

Definition

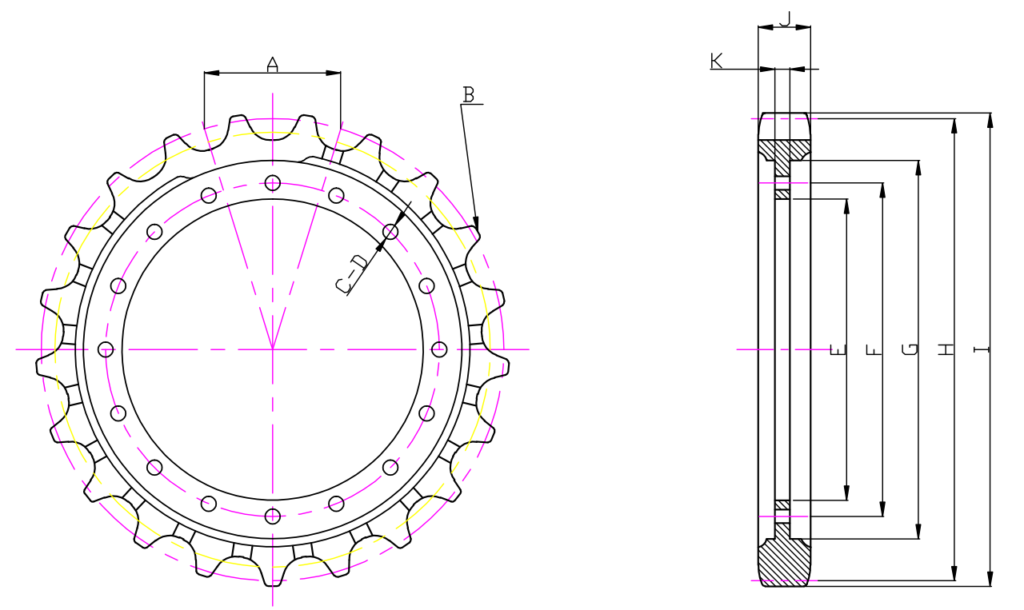

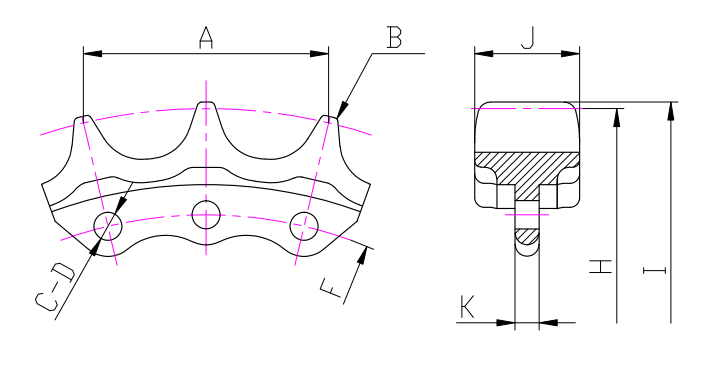

Excavator sprockets are toothed wheels that engage with the excavator’s track chain, facilitating smooth movement and precise control. Segments, on the other hand, are modular sections of a sprocket’s outer ring, typically used in larger excavators, offering easy replacement and extended lifespan.

Functions

- Power Transmission: Sprockets transfer power from the excavator’s engine to the tracks, enabling forward and backward movement.

- Load Distribution: Segments evenly distribute the load across the track, reducing wear and tear.

- Stability: Together, sprockets and segments ensure the excavator remains stable, even on uneven terrain.

Working Principle

The sprocket’s teeth engage with the track chain, converting rotational motion from the excavator’s drive motor into linear motion. Segments, when used, enhance this interaction by providing precise alignment and reducing stress on individual teeth.

Production Process of Sprockets and Segments

- Material Selection: High-strength alloy steel is chosen for its durability and wear resistance.

- Forging: The steel is forged under high pressure to enhance its toughness.

- Machining: CNC machines ensure precise dimensions and tooth profiles.

- Isıl İşlem: The parts undergo processes like quenching and tempering to achieve optimal hardness.

- Surface Finishing: Coatings are applied to protect against corrosion and improve longevity.

- Quality Inspection: Each piece is rigorously tested for dimensional accuracy, hardness, and surface finish.

How to Judge the Quality of Sprockets and Segments

- Material Quality: Look for high-grade steel and proper heat treatment.

- Precision Machining: Ensure the teeth are uniformly spaced and properly aligned.

- Surface Finish: Check for smooth, corrosion-resistant coatings.

- Durability: Ask for data on wear resistance and load capacity.

- Brand Reputation: Choose manufacturers like GFM with proven expertise and quality assurance.

Advantages of GFM Excavator Sprockets and Segments

- Premium Materials: GFM uses only the best alloy steels, ensuring maximum durability.

- Advanced Manufacturing: State-of-the-art CNC machines and heat treatment facilities guarantee precision and longevity.

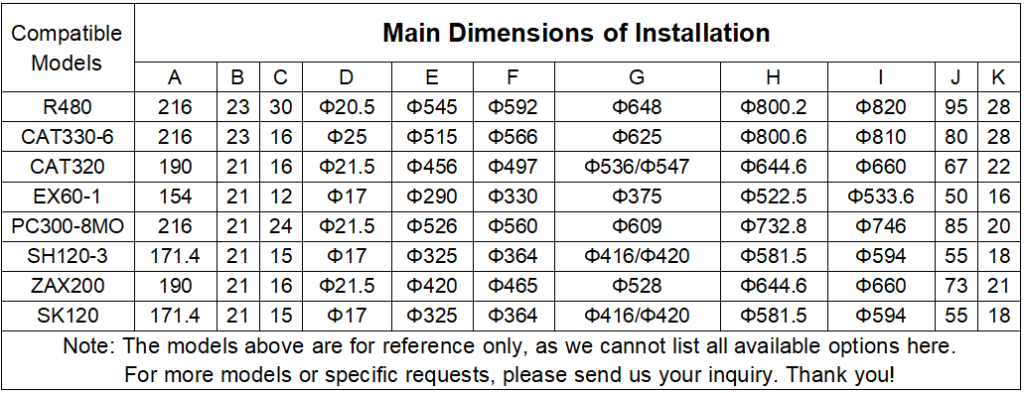

- Custom Solutions: We offer tailored designs to meet specific machinery requirements.

- Rigorous Quality Control: Our multi-stage inspection process ensures every product meets the highest standards.

- Global Support: With a robust supply chain and customer service team, GFM ensures timely delivery and support worldwide.

Maintenance Tips for Excavator Sprockets and Segments

- Regular Cleaning: Remove dirt and debris to prevent premature wear.

- Lubrication: Apply appropriate lubricants to minimize friction.

- Inspect for Wear: Check for signs of wear, such as thinning teeth or cracks.

- Replace When Necessary: Don’t delay replacing worn-out sprockets or segments to avoid damage to other components.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule recommended by GFM.

GFM Factory Strength and Expertise

Cutting-Edge Facilities

Our factory is equipped with advanced machinery, including automated CNC systems and heat treatment furnaces, ensuring consistent quality and efficiency.

Experienced Team

With decades of experience in the excavator parts industry, our engineers and technicians are experts in designing and manufacturing high-performance sprockets and segments.

Global Reach

With a network of distributors and partners worldwide, GFM is a trusted name in excavator parts, delivering top-notch products and services to clients across the globe.

Excavator track sprockets and segments are crucial for the smooth operation and longevity of your machinery. By choosing GFM, you’re investing in premium quality, unmatched expertise, and reliable customer support. Explore our range of sprockets and segments to find the perfect fit for your excavator and experience the GFM advantage.

For inquiries or to place an order, contact us today and let our experts guide you to the best solutions for your excavator needs.

E-posta: henry@gfmparts.com

Whatsapp: +86 17705953659