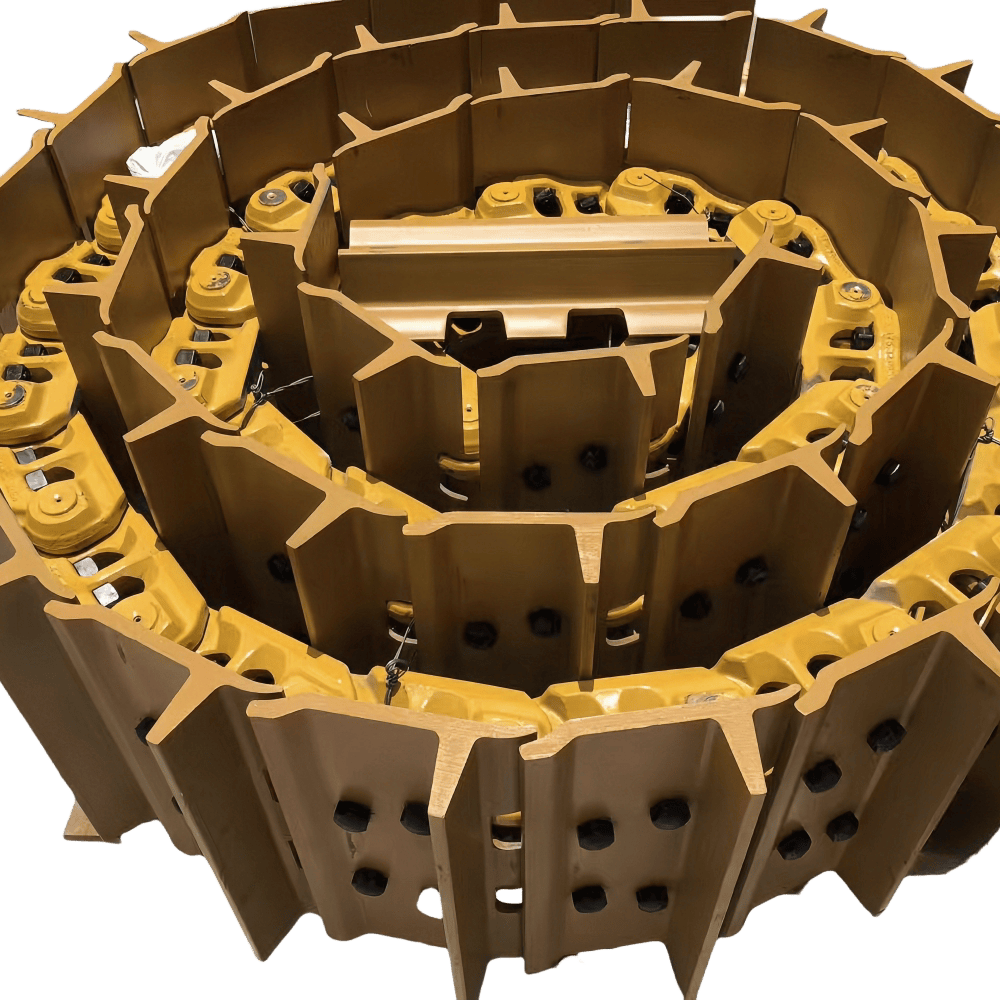

In modern construction and mining projects, excavators and bulldozers are the most common heavy machinery and equipment, and the track assembly is the key component that enables them to operate stably and efficiently under various working conditions. The track assembly consists of multiple components, such as track shoes, drive wheels, guide wheels, etc., which undertake functions such as support, traction, and stability.

Definition of track assembly

The excavator track assembly refers to all the components that support and drive the excavator to walk on different terrains. Its main function is to ensure that the excavator has excellent maneuverability and traction and adapts to various complex working conditions. The excavator track assembly includes track shoes, drive wheels, guide wheels, sprocket wheels, etc., and is usually used for earthwork, excavation, handling, demolition and other tasks.

The bulldozer track assembly is a key system for bulldozers to move and support heavy loads. Unlike excavators, the design of bulldozer track assemblies focuses more on load-bearing capacity, stability and wear resistance. Bulldozer track assemblies include tracks, track wheels, drive devices, etc., which are mainly used for leveling land, bulldozing, compaction and other operations, and are especially suitable for working in high-load working environments.

The role of track assemblies

Excavator track assemblies

The excavator track assemblies connect the excavator’s drive device to enable it to travel on rugged or slippery ground. The wide surface of the track disperses the weight of the equipment, reduces ground pressure, provides good traction, and enables the excavator to work stably in complex environments.

Bulldozer track assemblies

The bulldozer track assemblies transmit thrust, allowing the bulldozer to perform heavy operations such as bulldozing and shoveling at a lower speed in harsh terrain. Its design focuses on improving the ability to resist pressure and vibration, and reducing the wear of the tracks caused by long-term heavy-load operations.

Working principle of track assembly

Excavator track assembly

The excavator track assembly drives the track forward through the drive wheel, providing traction to support the movement of the excavator. The gears of the drive device and the track are matched, so that the track can evenly distribute the ground load, ensuring smooth operation in various working environments.

Bulldozer track assembly

When the bulldozer track assembly is working, the drive wheel drives the track to rotate around the track wheel through friction, generating forward thrust and pushing the machine to complete the bulldozing operation. Bulldozer tracks are usually made of thicker and stronger materials than excavator tracks to withstand greater pressure and long-term high-load work.

Production process

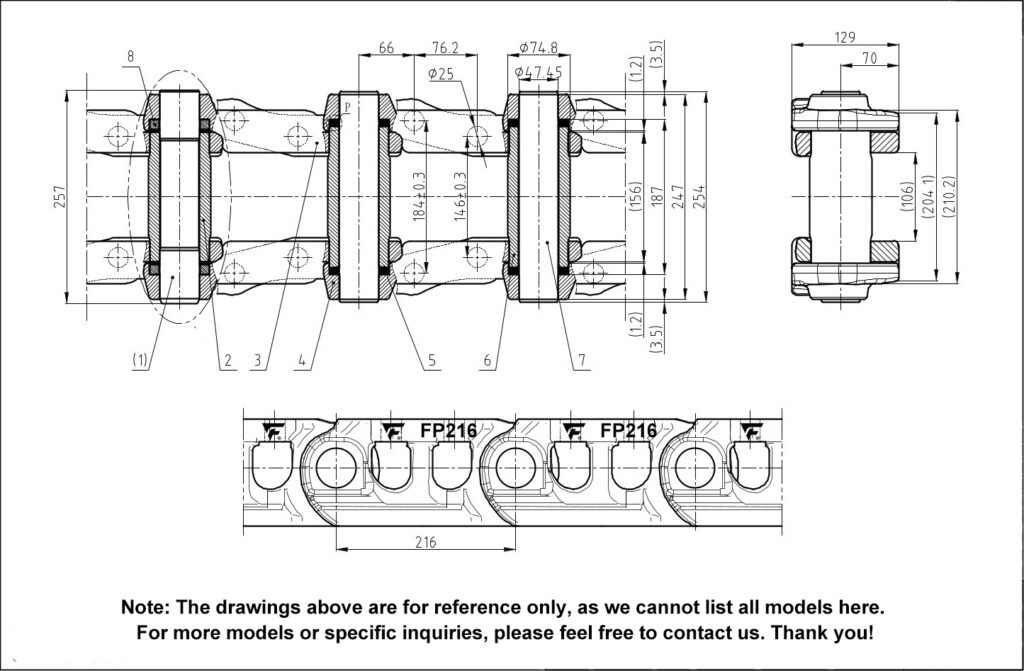

The production process of the track chain assembly is very complex and requires precise technology and strict quality control. The following is the production process of the track assembly:

Design and R&D

Customized design is carried out according to customer needs and equipment usage conditions. Load capacity, stability and fatigue resistance should be considered during design.

Material selection and processing

High-strength alloy steel is the preferred material for making track assemblies, with excellent wear resistance, corrosion resistance and pressure resistance. All materials must undergo strict heat treatment before entering the production line.

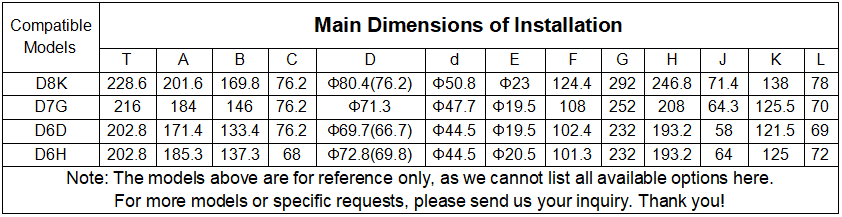

Precision machining

Track shoes, drive wheels, guide wheels and other components are precision machined by CNC equipment to ensure accurate dimensions, tight fit, and meet high standards of industrial requirements.

Welding and assembly

The various parts of the track assembly are connected by high-strength welding technology to ensure stability and durability between components.

Strict quality inspection

All track assemblies need to undergo a number of strict quality inspections, including fatigue tests, friction tests, wear tests, etc., to ensure their efficiency and safety in actual operations.

Packaging and transportation

Each track assembly will be professionally packaged after inspection to ensure that it is not damaged during transportation.

The main difference between excavator and bulldozer track assemblies

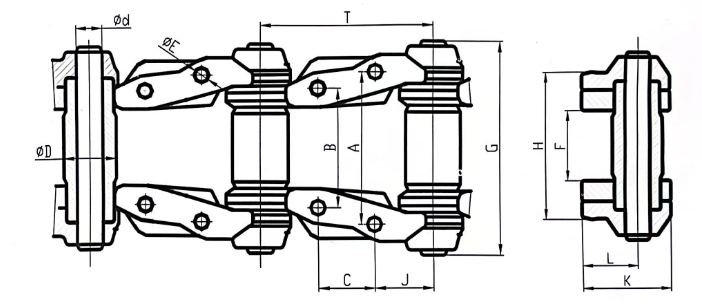

There are significant differences in design, structure and use environment between excavator track assemblies and bulldozer track assemblies. Here are their detailed differences:

Track Shoes

- Excavator track shoes: usually thinner and more sophisticated to reduce weight and improve maneuverability. They are made of light alloy steel and have an anti-wear coating on the surface to extend service life.

- Bulldozer track shoes: thicker and stronger, using stronger wear-resistant alloy steel to ensure long-term operation in high-load working environments.

Drive wheels and track wheels

- Excavator drive wheels: smaller, usually with a double-row gear design to increase driving force. In order to reduce noise and wear, the design is more sophisticated.

- Bulldozer drive wheels: larger, with a more rugged gear design, capable of withstanding greater workloads. Bulldozer track wheels are usually single-row designs for enhanced stability.

Chain design

- Excavator chain: relatively light, with smaller gaps between chain links and smoother friction surfaces to improve walking efficiency.

- Bulldozer chain: heavier and stronger, with larger gaps between chain links to enhance durability and carrying capacity.

Advantages of track assemblies for excavators and bulldozers

Advantages of track assemblies for excavators

- High mobility: adapt to various complex terrains and can move flexibly in a small space.

- Lower load operation: capable of precise excavation and handling, suitable for various earthwork operations.

- Durability: using advanced materials and precision manufacturing processes to extend service life.

Advantages of track assemblies for bulldozers

- High load capacity: able to remain stable in heavy-load operations and not easy to wear.

- Strong wear resistance: bulldozer tracks are made of stronger materials to adapt to long-term, high-intensity working environments.

- Low maintenance cost: reasonable design reduces wear and maintenance frequency and reduces overall operating costs.

Daily maintenance of track assemblies for excavators and bulldozers

Regular maintenance and maintenance of track assemblies can effectively extend service life and reduce maintenance costs. The following are common maintenance recommendations for the two track assemblies:

- Check the tension of the crawler: Check the tension of the crawler regularly to avoid being too loose or too tight, which affects the normal operation of the equipment.

- Check the wear of the drive wheel and track shoe: For excavators and bulldozers, it is necessary to regularly check the wear of the track pad, drive wheel and track wheel, and replace the severely worn parts in time.

- Cleaning and lubrication: Regularly clean the mud and sand on the track chain and wheel set, and perform lubrication and maintenance to reduce friction.

- Check the shock absorption system: Check the shock absorption system of the track assembly to ensure that it can effectively buffer pressure and vibration during operation.

GFM factory advantages and strengths

As a leading track link assembly manufacturer, GFM stands out in the industry with the following advantages:

- Exquisite manufacturing technology: GFM uses advanced CNC processing technology and automated production lines to ensure the accuracy and quality of each track assembly.

- Sıkı kalite kontrol sistemi: All track assemblies undergo a strict quality inspection process to ensure that they meet international quality standards and have long-term reliability.

- Customized service: According to customer needs, GFM can provide customized solutions for track assemblies of different models and different application scenarios to meet various engineering needs.

- Continuous innovation capability: GFM has a strong R&D team that continuously improves the performance and design of the track system to adapt to market changes and technological advances.

E-posta: henry@gfmparts.com

Whatsapp: +86 17705953659