Track shoes are an important part of construction machinery such as excavators and bulldozers, and directly affect the traction, stability and operating efficiency of the equipment. For the majority of users of construction equipment, understanding the basic knowledge, distinguishing features, production processes and maintenance points of track shoes can not only help improve the service life of equipment, but also reduce operating costs.

Definition and working principle of track shoes

Track shoes are a metal component installed on the track chain link, usually made of high-strength steel, and are widely used in construction machinery such as crawler excavators and bulldozers. The main functions of track shoes include:

- Support equipment weight: disperse the gravity of the machinery and reduce the pressure on the ground, especially suitable for soft ground.

- Enhance traction: provide strong grip through contact with the ground to ensure the normal operation of the equipment in muddy, sandy or stone environments.

- Protect the ground: Compared with wheeled equipment, track shoes reduce damage to the ground, especially on sensitive terrain.

- Ensure stability: large area grounding provides good balance performance and prevents equipment from tipping over.

Design features and differences between excavator and bulldozer track shoes

Excavator track shoes

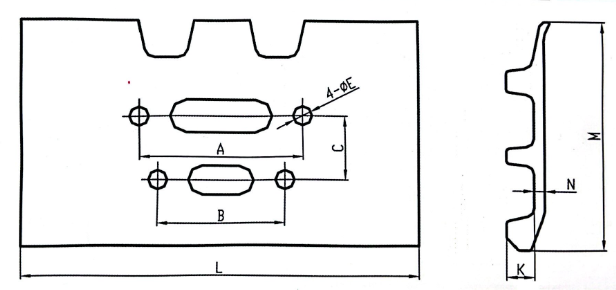

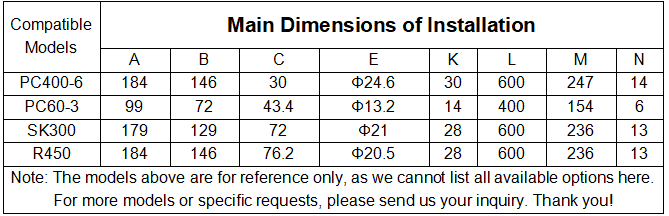

- Stability and off-road capability: Excavator track shoes usually use wider track shoes to increase the contact area with the ground, improve stability and off-road capability. In addition, excavator tracks also have a better suspension system to cope with complex terrain and operation requirements.

- Structural features: Most excavators use double-rib/triple-rib track shoes, and a few use flat-bottom track shoes. The three-rib track shoe is designed with ground contact pressure and meshing soil capacity between the ribs and the ground to ensure the necessary adhesion, while having high bending strength and wear resistance.

Bulldozer track shoes

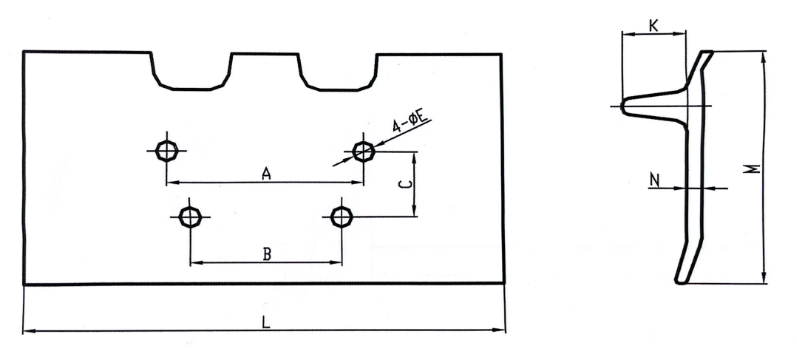

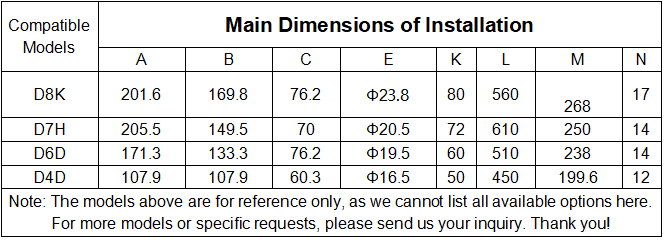

- Thrust and efficiency: Bulldozer track shoes pay more attention to thrust and efficiency, and usually use narrower track shoes to reduce friction resistance with the ground and increase travel speed.

- Structural features: Bulldozer track shoes are mostly single-rib designs, which can provide better traction in bulldozing operations. In addition, the suspension system of bulldozer tracks is relatively simple, and it focuses more on improving the efficiency of bulldozing operations.

Track plate production process

GFM, as a leading manufacturer of engineering machinery parts, strictly controls the production process of track plates to ensure the quality and performance of each product.

Material selection

High-strength wear-resistant steel is used to ensure that the track plates can withstand long-term heavy pressure and wear.

Precision casting or forging

- Excavator track plates usually use forging technology to improve the toughness of the plate.

- Bulldozer track plates are mostly cast to enhance wear resistance.

Machining

Precision cutting, drilling and surface treatment of the track plates to ensure a perfect fit with the chain links.

Heat treatment

The hardness and durability of the track plates are improved through quenching and tempering processes.

Surface anti-corrosion treatment

Spraying or galvanizing processes are used to improve the rust resistance of the track plates.

Quality inspection

Each track plate must pass strength tests, wear tests and size tests to ensure that it meets industry standards.

Advantages of track shoes

- High wear resistance: the combination of selected materials and advanced technology significantly extends the service life.

- Strong adaptability: suitable for a variety of complex terrains and harsh environments.

- High economic efficiency: reduce downtime caused by replacement of accessories and reduce maintenance costs.

- Green and environmentally friendly: low ground damage rate, suitable for construction in ecologically sensitive areas.

Daily maintenance and care of track shoes

Cleaning and maintenance

- After operation, remove foreign objects such as mud, sand, and stones on the crawler shoes in time to avoid excessive wear.

- Especially after working in harsh environments, the surface condition of the board should be checked.

Regular inspection

- Check whether the crawler shoes have cracks or severe wear, and replace the problem parts in time.

- Regularly measure the tension of the crawler chain links to avoid looseness or over-tightening that affects the performance of the crawler shoes.

Lubrication and maintenance

- Regularly lubricate the crawler system to reduce wear and ensure smooth operation of the equipment.

Correct operation

- Avoid frequent sharp turns or high-load operations to reduce the pressure on the crawler shoes.

Advantages of GFM track shoes and factory strength

R&D and design capabilities

GFM has a professional R&D team that can design high-performance track shoes according to different equipment and working conditions to meet the diverse needs of global customers.

Advanced production equipment

The factory is equipped with fully automated production lines and intelligent testing equipment to ensure product consistency and high quality.

Strict quality management system

In accordance with the ISO9001 quality certification standard, GFM strictly controls each production link, and the qualified rate of track shoes is as high as 99.8%.

Global supply chain system

GFM’s track shoes have been exported to more than 50 countries and regions and have won unanimous praise from customers.

Perfect after-sales service

Provide fast-response technical support and spare parts services to help customers solve practical problems.

As an important component of excavators and bulldozers, the quality and performance of track shoes directly affect the operating efficiency and life of the equipment. By choosing high-quality track shoes and performing scientific maintenance, you can not only improve equipment performance, but also significantly reduce operating costs. As an industry-leading track shoe manufacturer, GFM is committed to providing high-quality track shoes and other accessories to global customers to help your construction machinery perform at its best.

If you are interested in our products or have any questions, please feel free to contact our technical team!

E-posta: henry@gfmparts.com

Whatsapp: +86 17705953659