In the huge mechanical structure of excavators and bulldozers, track shoe bolts and nuts play a vital role as important components for connection and fixing. As a GFM excavator and bulldozer parts manufacturer, we are committed to providing customers with high-quality track shoe bolts and nuts products to ensure the efficient operation and safety performance of the equipment.

What are track shoe bolts and nuts?

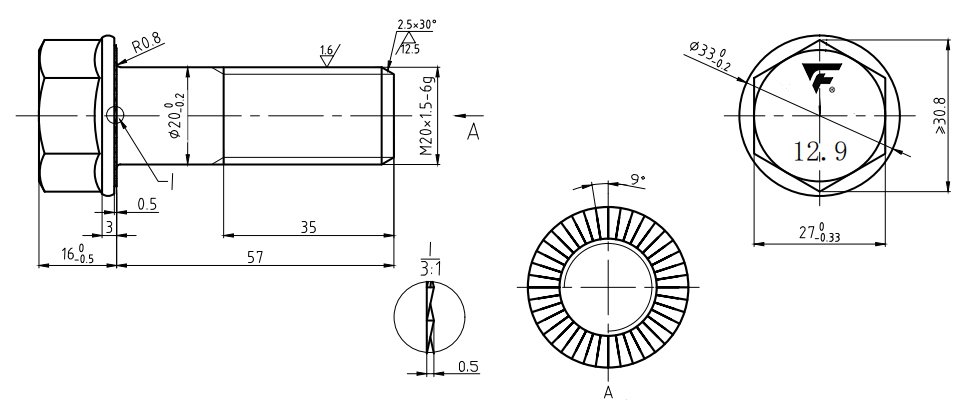

Screws, commonly known as bolts, have external threads and are usually used to connect and fix mechanical parts. Nuts are usually hexagonal in shape and have internal threads in the inner hole, which are used to cooperate with bolts to tightly fix related parts together. In the chain plate structure of excavators and bulldozers, the track shoe bolts and nuts combination plays a key role in connection and fixing. These track shoe bolts and nuts not only bear the weight of the equipment, but also need to withstand complex working environments, including high temperature, vibration, impact and sediment erosion.

Function and principle

Function

- Fixed chain rail system: ensure stable connection between track shoe and chain rail section to prevent loosening or breakage.

- Transmit power: through cooperation with the chain rail, the power output of the engine is transmitted to the ground to ensure the smoothness and accuracy of equipment movement.

- Impact and wear resistance: Provide strong impact and wear resistance in high-load working environments, extending the service life of the chain rail system.

Working principle

The track shoe bolts are tightened with the nuts through their threads to form a strong clamping force, firmly fixing the track shoe and the chain rail section. High-strength materials and precision manufacturing processes ensure that the bolts and nuts will not loosen or deform under high pressure and high friction environments.

Production process

The production process oftrack shoe bolts and nuts mainly includes the following steps:

- Hammadde seçimi: Select high-strength alloy steel, such as 40Cr and 42CrMo, to ensure the strength and toughness of the product.

- Steel stamping: The steel is processed into the preliminary shape of the bolt and nut through a stamping process.

- Tapping: Process threads on the bolt shank and the inner hole of the nut.

- Heat treatment: Heat treatment of bolts and nuts to improve their hardness and strength.

- Yüzey işleme: Electroplating or spraying of bolts and nuts to enhance their corrosion resistance and aesthetics.

- Quality inspection: After hardness test, tensile strength test and fatigue test, ensure that each screw and nut meets international standards.

How to judge quality

The quality of grouser track bolts and nuts can be judged from the following aspects:

- Appearance inspection: The surface of high-quality bolts and nuts should be smooth and flat, without defects such as burrs, cracks, pits, etc.

- Thread regularity: The thread should be clear and uniform, without deformation, missing teeth, random buckles and other problems.

- Material identification: Through magnet detection and hardness test and other methods, judge whether the material of the bolts and nuts meets the requirements.

- Mechanical properties: Through tensile strength and torque test and other methods, check whether the mechanical properties of the bolts and nuts meet the standards.

Advantages of GFM track shoe bolts and nuts

GFM, as a leader in the manufacturer of excavator and bulldozer parts, has the following significant advantages in its track shoe bolts and nuts:

- High precision: Using advanced production equipment and processes to ensure the accuracy and fit of bolts and nuts.

- High strength: After strict heat treatment process, the hardness and strength of bolts and nuts are improved to meet the high-load operation requirements of excavators and bulldozers.

- Corrosion resistance: Use high-quality materials and advanced surface treatment technology to improve the corrosion resistance of bolts and nuts.

- Easy to install: Reasonable design of thread and head shape for easy installation and disassembly.

Daily maintenance

To ensure the long-term stable operation of track shoe bolts and nuts, daily maintenance is essential:

- Regular inspection: Regularly check the tightness of bolts and nuts to ensure that there is no loosening or falling off.

- Timely replacement: When the bolts and nuts are found to be worn or damaged, they should be replaced in time to avoid causing more serious failures.

- Lubrication and maintenance: Regularly lubricate and maintain the bolts and nuts to reduce friction and wear.

- Cleaning and maintenance: Regularly clean the dirt and dust on the surface of the bolts and nuts to keep them clean and beautiful.

Factory strengths and advantages

As a leading manufacturer of excavator and bulldozer parts, GFM Factory’s strengths and advantages are mainly reflected in the following aspects:

- Advanced production equipment: With advanced production equipment and technology to ensure product quality and production efficiency.

- Sıkı kalite kontrolü: Establish a complete quality control system, from raw material procurement to product delivery, every link is strictly controlled.

- Rich production experience: With many years of production experience and technical accumulation, we can provide customers with high-quality products and services.

- Professional R&D team: With a professional R&D team, we continuously develop new products and technologies to meet the diverse needs of customers.

As an important component of excavators and bulldozers, the quality and performance of track shoe bolts and nuts are directly related to the stability and durability of the equipment. As a leader in the manufacturer of excavator and bulldozer parts, GFM has won the trust and praise of customers for its track shoe bolts and nuts with its high precision, high strength, corrosion resistance and easy installation. At the same time, the strength of the GFM factory also provides customers with high-quality product and service guarantees.

E-posta: henry@gfmparts.com

Whatsapp: +86 17705953659