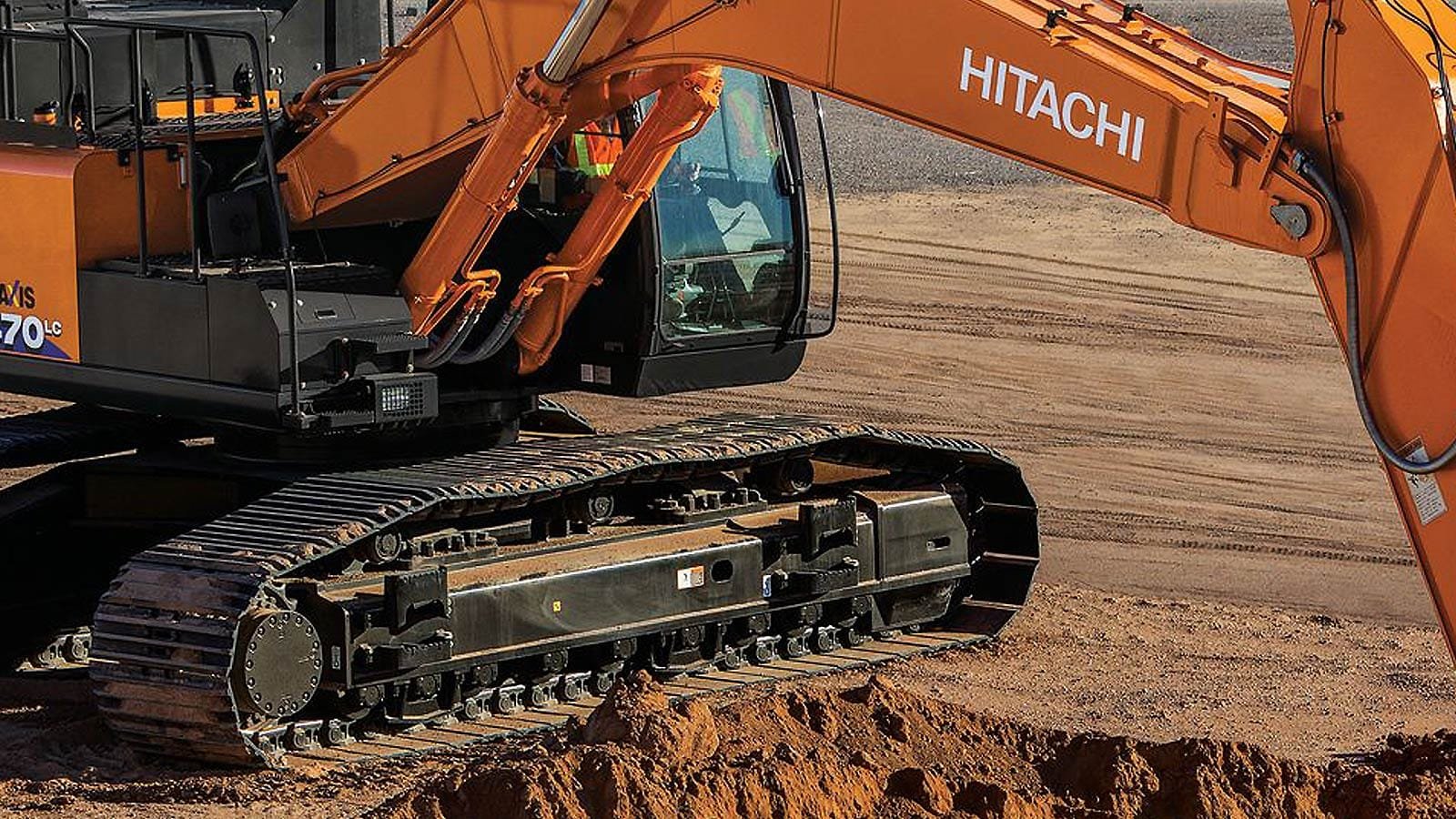

In the field of construction machinery, excavators undoubtedly play an important role. The performance and stability of excavators depend largely on the design and manufacture of their undercarriage parts. Today, we will take a deep look at the relevant knowledge of excavator undercarriage parts, and especially introduce the characteristics and factory strength of GFM excavator undercarriage parts.

What are excavator undercarriage parts?

The ekskavatör alt takım parçaları are the support and walking system of the excavator, which ensures the stability and operating efficiency of the excavator on various complex terrains. The undercarriage parts include crawler tracks, crawler frames, drive wheels, guide wheels, supporting rollers, sprocket wheels and other key components.

Composition of undercarriage parts

- Tracks assembly: composed of crawler plates and chain links, responsible for providing sufficient friction to ensure that the excavator can operate stably on slopes or slippery ground.

- Crawler frame: the main structure supporting the crawler track, usually welded from high-strength steel.

- Driving roller: meshes with the crawler track through the gear ring to provide forward power.

- Excavator idler: guides the crawler track to run on the correct track to prevent yaw.

- Bottom roller: distributed on both sides of the track, supporting the weight of the excavator and reducing track wear.

- Carrier roller: lifts and supports the track chain to prevent it from sagging and excessive wear.

Function and principle

The main function of the undercarriage components is to support the weight of the entire excavator, ensure that the excavator can operate stably on various terrains, and realize the walking function through the rotation of the drive wheel. In principle, when the engine provides power, it is transmitted to the drive wheel through the transmission system, and the drive wheel drives the track to rotate, thereby realizing the movement of the excavator. At the same time, the roller and guide wheel work together to ensure that the track runs on the correct track and maintain the stability of the excavator.

Production process

The production process of GFM excavator undercarriage components strictly follows high quality standards:

- Raw material procurement: select high-strength, wear-resistant and corrosion-resistant high-quality steel.

- Precision machining: cutting, drilling, milling and other processing are carried out through high-precision CNC machine tools to ensure the precise size of the components.

- Welding and assembly: advanced welding technology and automation equipment are used to ensure that the welds are firm and beautiful. Then precision assembly is carried out to ensure that the components fit closely.

- Quality inspection: Welds are inspected for quality by means of X-ray inspection, magnetic particle inspection, etc. to ensure that there are no defects.

- Performance test: Performance test is carried out under simulated working conditions to ensure that the chassis components meet the design requirements.

- Packaging and delivery: Special packaging materials are used to ensure that the components are not damaged during transportation.

Features and advantages of GFM excavator undercarriage components

The features and advantages of GFM excavator undercarriage components are mainly reflected in the following aspects:

Excellent durability:

- High-strength material: GFM uses high-quality alloy steel, which is specially treated to give chassis components excellent strength and toughness, and can withstand heavy loads and impacts in extreme working environments.

- Wear resistance: After precise heat treatment and surface treatment technology, the surface hardness of GFM chassis components is significantly improved, effectively resisting wear and corrosion and extending service life.

High-precision manufacturing:

- Advanced technology: GFM uses advanced CNC machine tools and processing technology to ensure that the dimensional accuracy and shape accuracy of chassis components meet high standards, improve assembly accuracy and overall machine performance.

- Strict testing: During the production process, GFM implements strict quality testing, including dimensional measurement, material performance testing, etc., to ensure that every product meets high quality standards.

High stability and reliability:

- Structural optimization: The design of GFM undercarriage components has been carefully calculated and optimized to ensure that the excavator can still maintain high stability and operating efficiency under complex terrain and extreme operating conditions.

- Low failure rate: With the use of high-quality materials and precise manufacturing processes, the failure rate of GFM undercarriage components is significantly reduced, reducing downtime and maintenance costs.

Easy maintenance and replacement:

- Modular design: GFM undercarriage components adopt modular design, which is easy to disassemble and replace, reducing maintenance difficulty and cost.

- Standardized interface: The interface design of GFM undercarriage components is standardized, which is easy to be compatible and interchangeable with other components, and improves maintenance efficiency.

Customized service:

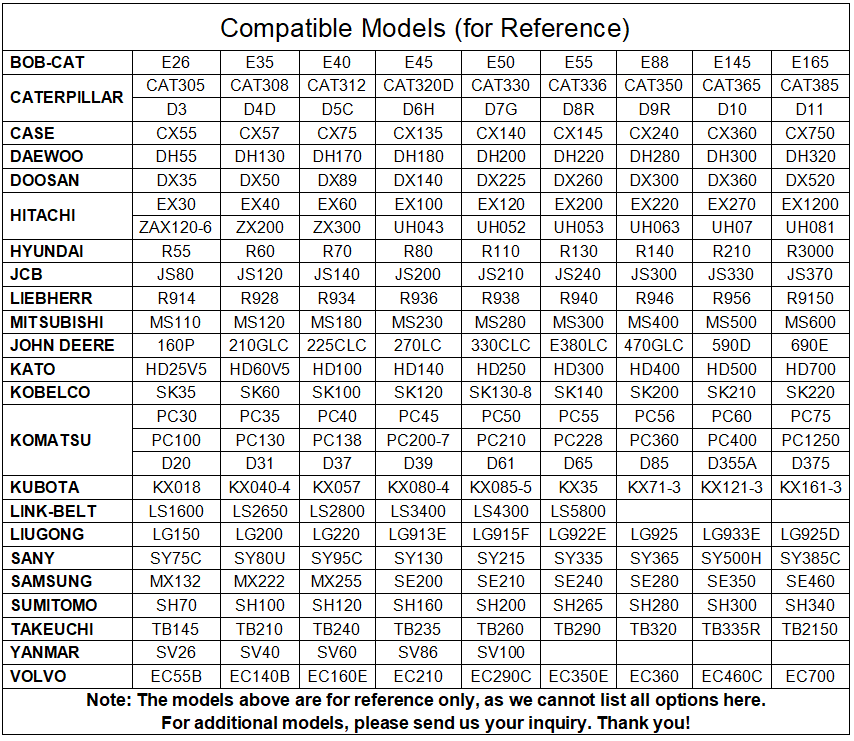

- Customer demand orientation: GFM provides customized undercarriage component services, and tailors chassis components that meet the requirements according to the specific needs and operating environment of customers.

- Flexible customization: Whether it is size, material or performance requirements, GFM can provide flexible customization solutions to meet the personalized needs of customers.

GFM professional excavator parts factory

GFM, as an ekskavatör alt takım parçaları üreticisi, has strong factory strength:

- Advanced production equipment: Introduce advanced production equipment and technology from home and abroad to ensure product quality and production efficiency.

- Strict quality management system: Establish a complete quality management system, from raw material procurement to finished product delivery, every link is strictly controlled.

- Professional R&D team: Have a professional R&D team dedicated to the innovative research and development of chassis parts, and continuously improve product performance and quality.

- Perfect after-sales service: Provide perfect after-sales service, including technical support, maintenance, parts supply, etc., to ensure that customers get timely and professional help during use.

GFM excavator undercarriage parts have won wide recognition and praise in the field of engineering machinery with its excellent performance, high-quality production technology and strong factory strength. We believe that in the future development, GFM will continue to maintain its leading position and provide customers with better products and services.

E-posta: henry@gfmparts.com

Whatsapp: +86 17705953659