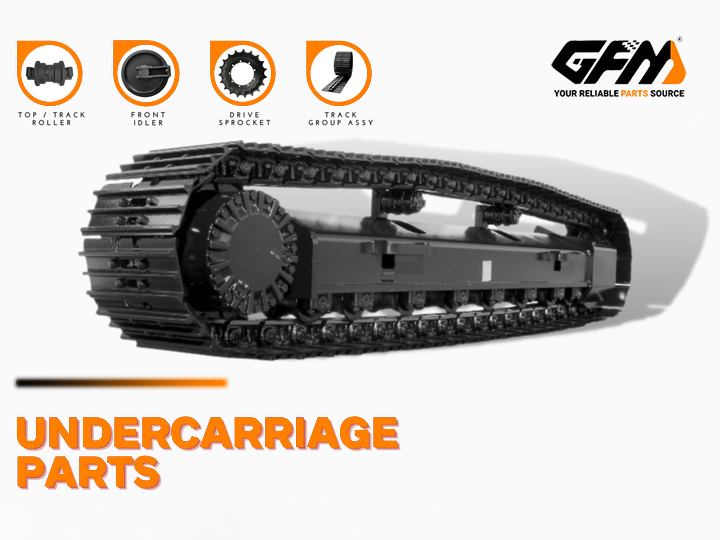

In heavy machinery and equipment, the undercarriage system plays a vital role. Accessories such as rollers, sprockets, and chains not only ensure the normal operation of the machine, but also directly affect the work efficiency and service life of the equipment. Therefore, the correct installation and use of these undercarriage accessories are crucial to the long-term stability of mechanical equipment.

Overview of undercarriage accessories

- Track roller: The roller is an important part of the chassis system that supports the operation of the chain, helping to share the weight of the machine and ensure smooth operation of the chain. Commonly found in crawler engineering machinery.

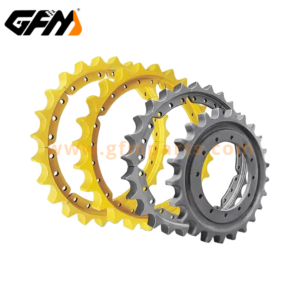

- Zincir dişlisi: The sprocket is a gear used in conjunction with the chain, usually connected to the drive system, which can effectively transmit power and drive the crawler forward.

- Chain: The chain is a key transmission component of the chassis system, responsible for transmitting power from the sprocket to the crawler, thereby driving the movement of the entire machine.

High Quality Bottom Roller Manufacturer

Product Quality Guaranteed Large SupplyCompetitive PricingMost Makes & ModelsHelpful Customer Service TeamProfessional Tech Support

Preparation for installing undercarriage accessories

Before starting the installation, you need to do the following preparations:

- Check the accessories: Make sure that the components such as rollers, sprockets, and chains are not damaged. The connection point of the chain should be free of cracks, the gears of the sprocket should be intact, and the support wheel should not have obvious wear.

- Tool preparation: Prepare the tools required for installation, such as wrenches, lifting tools, lubricating oil, screwdrivers, etc.

- Environmental preparation: Ensure that the working environment is flat and safe to avoid environmental factors affecting the installation process.

Installation process of support roller, sprockets and chains

Installing sprockets

The installation steps of sprockets are critical. Improper operation may cause accelerated wear of gears or mismatch with the chain. Here are the installation steps:

- Step 1: First align the sprocket with the drive shaft. Make sure that the inner hole of the sprocket fits well with the drive shaft.

- Step 2: Use bolts to fix the sprocket to the drive shaft. Maintain uniform force when tightening the bolts to avoid uneven pressure that affects the rotation of the sprocket.

- Step 3: Check the meshing degree of the sprocket and the chain. Make sure that the tooth surface of the sprocket and the contact surface of the chain are completely consistent without jamming.

Installing the chain

The installation of the chain is essential for the operation of the chassis system. Pay special attention to the tension and installation position of the chain during installation.

- Step 1: Hang one end of the chain on the sprocket. Make sure there are no obstacles on the contact surface between the chain and the sprocket.

- Step 2: Make sure the chain is at the appropriate tension by adjusting the chain tensioner (such as the adjusting bolt). A loose chain will cause slippage, while a tight chain will increase the wear of the chain and sprocket.

- Step 3: Follow the path of the chain and make sure that the rest of the chain fits well with all rollers, rollers, sprockets and other accessories.

Install the rollers

The main function of the rollers is to support the chain and reduce friction to ensure smooth operation of the chain.

- Step 1: Fix the rollers in place. The rollers are usually installed on both sides of the track or on the chassis to ensure that they can evenly support the entire chain.

- Step 2: Tighten the rollers with appropriate tools to ensure that they are stably fixed. If the rollers have an adjustment function, you need to ensure that the distance between the rollers and the chain is reasonable.

- Step 3: Check whether the support roller rotates smoothly and confirm that there is no abnormal wear or jamming.

Inspection and adjustment after installation

After installation, you need to perform a series of inspections and adjustments to ensure that the performance of the chassis accessories is in the best condition.

- Check the chain tension: The chain should not be too tight or too loose. A loose chain will cause wear, and a too tight chain will increase the load on the equipment. Use the tensioner to make fine adjustments to ensure that the chain maintains proper tension.

- Check the fit between accessories: Check whether the sprocket, chain and support roller fit perfectly to ensure that there is no friction or abnormal wear.

- Test the operation of the equipment: Check whether the operation is smooth when the equipment is idling, whether the chain passes smoothly through each support roller and sprocket, and whether there is abnormal noise or vibration.

- Lubrication check: Ensure that key parts such as chains, sprockets and support rollers are well lubricated. Check regularly whether the lubricating oil is sufficient to prevent component wear due to insufficient lubrication.

Use and maintenance of undercarriage accessories

Correct use and regular maintenance are essential to extend the service life of chassis accessories.

Daily inspection

- Check the tension of the chain regularly and adjust it in time according to the usage.

- Check whether the gears of the sprocket are worn, and replace them in time if abnormalities are found.

- Check the operation of the roller regularly to ensure that it is not deformed or damaged.

Lubricate regularly

Lubrication of chassis accessories is essential. Maintaining proper lubrication can reduce friction, reduce wear, and increase the service life of accessories. Lubricate the chain, sprocket, and roller regularly with appropriate lubricants.

Avoid overload operation

Avoid running the equipment under overload. Overload will increase the burden on the chain and sprocket, causing accelerated wear and shortening the service life. Control the intensity of use according to the rated load of the equipment.

Replace worn parts in time

Undercarriage accessories will gradually wear over time, especially chains and sprockets. Regularly check and replace severely worn parts in time to prevent them from affecting the operation of the entire chassis system.

| Hızlı ve ücretsiz bir teklif alın | E-posta: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Correct installation and use of excavator undercarriage part such as rollers, sprockets, chains, etc. can not only ensure the normal operation of the equipment, but also extend the service life of the equipment. Details during the installation process cannot be ignored. Reasonable adjustments and regular maintenance will help you maximize the performance of chassis accessories. After installation, regular inspection and maintenance of the equipment to keep it in good working condition is the key to ensuring long-term and efficient operation of the equipment.