Kato HD700 Ekskavatör Paletli Rölanti

- Ürün Kalitesi Garantili

- Büyük Arz

- Rekabetçi Fiyatlandırma

- Çoğu Marka ve Model

- Yardımsever Müşteri Hizmetleri Ekibi

- Profesyonel Teknik Destek

Paylaşmak

If you are looking for a track idler that is suitable for Kato HD700 excavator, has stable performance and long service life, then you have come to the right place. As an excavator idler suppliers focusing on the manufacture of excavator chassis parts, GFM not only provides standard track idler products, but also provides customized services according to customer needs to help you cope with a variety of construction conditions and maintenance scenarios.

Why is it important to have a track idler suitable for Kato HD700?

The excavator track idler mainly plays the role of supporting and guiding the crawler in the excavator track system. It is located at the front end of the crawler and is connected to the tensioning device. It plays a vital role in maintaining the tension of the crawler and reducing the wear of the crawler. Especially on medium-sized crawler excavators such as Kato HD700, the construction intensity is high and the working time is long, which requires more stringent durability and stability of the idler.

Choosing high-quality idlers can not only improve the stability of the whole machine, but also extend the service life of the crawler and chain rail, reduce the maintenance frequency, and thus save time and cost.

GFM Track Idler Product Advantages

We adhere to high standards and strict processes in the production of idlers, and every detail has been repeatedly polished and verified. The idler products suitable for Kato HD700 have the following characteristics:

High-strength forged structure

We use high-quality alloy steel materials for integral forging to ensure that the idler has good impact resistance and load-bearing capacity. The forgings are dense and not easy to crack, and can cope with high-intensity working conditions.

Heat treatment and tempering process

Each idler is tempered and medium-frequency induction quenched, and the surface hardness can reach HRC52~58, which effectively improves its wear resistance. At the same time, it maintains a good internal stress distribution to avoid fractures caused by excessive hardness.

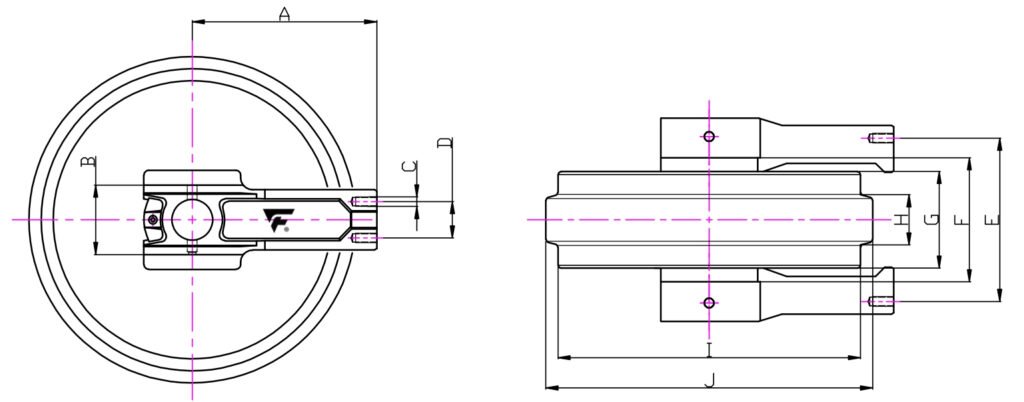

Precise size control

Our CNC lathe processing ensures that the idler is precisely matched with the shaft hole and tolerance position, which is easy to install, runs smoothly, is not easy to eccentric, and will not cause additional burden on the chain track system.

Double seal design

The idler bearing part adopts a double oil seal structure (floating oil seal + dust ring), which has stronger sealing performance, effectively preventing mud and water from entering the bearing, and extending the overall service life. Even in rainy days, wetlands or swamp construction environments, it can ensure normal operation.

High installation matching degree

We strictly develop and design according to the original standard drawings of Kato HD700 to ensure accurate hole position and seamless installation. It can be directly replaced without modification, and the maintenance efficiency is high.

Ürün Açıklaması

- Minimum Sipariş Adedi: 1 Bilgisayar

- Ödeme yöntemi: T/T

- Marka: GFM

- Durum: Yeni

- Renk: Sarı, Siyah veya Özelleştirilmiş

- Kurşun zamanı: 30 gün

- Garanti: 1 Yıl

- Hizmet: OEM veya ODM

- Menşei Yeri: Fujian, Çin

- Başvuru: Ekskavatör

- Paketleme: Standart İhracat Ahşap Palet

Özellikler

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Özellikler

Ürün Modelleri

Üretim Süreci

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Material refining

Select high-strength bearing steel, and improve the purity of the metal through refining, deoxidation and electroslag remelting processes

The chemical composition of the material is stable and can effectively resist fatigue cracks and impact loads - CNC machining

In the rough machining stage, a high-power CNC milling machine is used to quickly shape the blank and strictly control the allowance

In the fine machining stage, a multi-axis linkage CNC lathe and grinder are used to ensure the dimensional accuracy of the outer circle, inner hole and tooth surface - Heat treatment strengthening

The segmented quenching + low-temperature tempering process is adopted, and the hardness is uniform, with high wear resistance and toughness

Accurately monitor the quenching temperature and holding time to ensure that the internal structure of the parts is stable and crack-free - Surface treatment

Shot peening, phosphating, nitriding and other processes can be selected according to customer needs to further improve fatigue resistance

Under special working conditions, an environmentally friendly high-temperature resistant coating is provided to delay wear and corrosion - Strict testing and packaging

Comprehensive use of three-coordinate measuring instruments, roundness meters and hardness testers to ensure that key dimensions and mechanical properties meet the standards

Dust-proof and moisture-proof packaging, and customized packaging solutions can be provided according to the mode of transportation

Paketleme ve Nakliye

Fabrika Avantajları

GFM excavator idler manufacturers has been focusing on the production of undercarriage components, accumulating deep knowledge reserves and continuously improving production technology through thousands of practical applications. With more than ten years of industry experience, professional engineers and technicians, many of whom have more than 10 years of experience in undercarriage component manufacturing, covering R&D, quality control and production links.

Choosing the right idler for your Kato HD700 excavator can significantly improve uptime, maintenance costs and overall productivity. At GFM, we have rich experience, perfect quality systems and flexible customization services, making us a reliable partner for your excavator undercarriage components. Whether you operate a rental fleet, a large construction site or a mining operation, our idlers can meet your daily excavation needs.

Customized services make maintenance more flexible

Today, with the increasing diversity of global customer needs, GFM has long moved from traditional parts manufacturing to a personalized customized solution service provider. Whether you need:

- Thickened and widened idlers to cope with mining or heavy-load conditions.

- Improved oil seal structure to adapt to special climates or construction site environments.

- Laser engraving LOGO or coding to meet brand identification needs.

We can customize solutions for you and deliver them quickly to meet the practical problems of tight maintenance windows.

Want to learn more or request a custom quote? Contact our friendly team today to keep your machine running smoothly!

2011 yılında kurulan Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, ekskavatör ve buldozer yedek parçalarında uzmanlaşmış deneyimli bir üreticidir. Bu parçalar arasında şasi parçaları (palet silindirleri, taşıyıcı silindirler, dingil makaraları, zincir dişlileri, palet pabuçları, palet zincirleri, palet grupları), cıvatalar, somunlar, pimler, burçlar ve daha fazlası yer almaktadır. Piyasadaki çoğu marka ve modele uygun geniş bir parça yelpazesini kapsıyor ve stoklarımızda bulunduruyoruz. Uyumlu markalar arasında Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG vb. yer almakta olup, piyasadaki ana akım markaları kapsamaktadır.

SSS

Deneyimli bir üreticiyiz. Fabrikamız Quanzhou Şehri, Xiamei Kasabası'nda bulunmaktadır. Ziyaretiniz memnuniyetle karşılanacaktır.

Lütfen bize doğru makine modelini, parça numarasını veya bazı teknik özellikleri belirtin. Standart ürünler değilse, lütfen çizimleri sunun.

Biz genelde T/T'yi kabul ediyoruz; diğer şartlar müzakere edilebilir.

Elbette yapabilirsiniz. OEM hizmeti veriyoruz. Numuneleriniz veya çizimleriniz varsa ve toplu sipariş talep ediyorsanız, ürünleri özelleştirebilir ve profesyonel teknik destek sağlayabiliriz.

GFM, eksiksiz bir kalite, çevre ve güvenlik kontrol sistemi kurmuştur. Her parça, dağıtımdan önce titiz testlerden ve kalite kontrol önlemlerinden geçer. Fabrikamız, üretim süreçlerinde sıkı güvenlik standartlarına ve çevre düzenlemelerine uymaktadır.

ŞİMDİ TEKLİF İSTEYİN

İlgili ürünler

- ALT TAKIM

En İyi Buldozer Alt Silindir Fabrikası