Kobelco SK380 Ekskavatör Rölanti Tedarikçileri

- Ürün Kalitesi Garantili

- Büyük Arz

- Rekabetçi Fiyatlandırma

- Çoğu Marka ve Model

- Yardımsever Müşteri Hizmetleri Ekibi

- Profesyonel Teknik Destek

Paylaşmak

Are you worried about the abnormal noise of the undercarriage or the slipping of the crawler track of Kobelco SK380? Don’t worry, GFM is committed to providing high-precision excavator track idler designed for SK380 to solve these problems! It is not only a replacement part, but also a high-performance product tailored for your equipment.

▍ Special vehicle, perfect fit

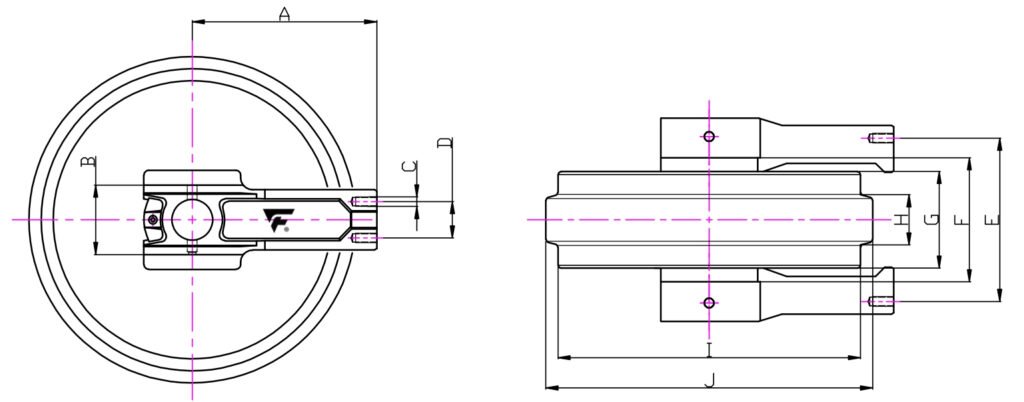

Each GFM idler is developed based on the Kobelco SK380 original drawing database, accurately matching the shaft diameter, mounting hole position and crawler pitch.

▍ High-quality material guarantee

• Material black technology: using forged alloy steel wheel body + double sealed bearing unit, the wear resistance is 3 times higher than that of ordinary carbon steel. Even if it is continuously operated for 3000 hours in a mine full of gravel, the wheel surface wear is ≤0.8mm.

• Anti-rust master: triple protection – first sandblasting to remove rust, then zinc-nickel alloy plating, and finally covering with UV-resistant epoxy resin paint.

Ürün Açıklaması

- Minimum Sipariş Adedi: 1 Bilgisayar

- Ödeme yöntemi: T/T

- Marka: GFM

- Durum: Yeni

- Renk: Sarı, Siyah veya Özelleştirilmiş

- Kurşun zamanı: 30 gün

- Garanti: 1 Yıl

- Hizmet: OEM veya ODM

- Menşei Yeri: Fujian, Çin

- Başvuru: Ekskavatör

- Paketleme: Standart İhracat Ahşap Palet

Özellikler

- Durable:Built to withstand tough conditions for long-lasting performance.

- Perfect Fit: Designed for easy installation on various excavator and bulldozer models.

- Heavy Duty: Supports heavy loads for smooth and stable operation.

- Smooth & Quiet: Minimizes vibration for smoother movement and improved traction on all terrains.

- Low Maintenance: Self-lubricating for less upkeep and more uptime.

- Weather-Resistant: Performs well in any climate, resistant to rust and extreme temperatures.

Özellikler

Ürün Modelleri

Üretim Süreci

From design to delivery, every process link of our products is strictly controlled to ensure product stability and durability. The following is an introduction to the basic process flow:

- Material refining

Select high-strength bearing steel, and improve the purity of the metal through refining, deoxidation and electroslag remelting processes

The chemical composition of the material is stable and can effectively resist fatigue cracks and impact loads - CNC machining

In the rough machining stage, a high-power CNC milling machine is used to quickly shape the blank and strictly control the allowance

In the fine machining stage, a multi-axis linkage CNC lathe and grinder are used to ensure the dimensional accuracy of the outer circle, inner hole and tooth surface - Heat treatment strengthening

The segmented quenching + low-temperature tempering process is adopted, and the hardness is uniform, with high wear resistance and toughness

Accurately monitor the quenching temperature and holding time to ensure that the internal structure of the parts is stable and crack-free - Surface treatment

Shot peening, phosphating, nitriding and other processes can be selected according to customer needs to further improve fatigue resistance

Under special working conditions, an environmentally friendly high-temperature resistant coating is provided to delay wear and corrosion - Strict testing and packaging

Comprehensive use of three-coordinate measuring instruments, roundness meters and hardness testers to ensure that key dimensions and mechanical properties meet the standards

Dust-proof and moisture-proof packaging, and customized packaging solutions can be provided according to the mode of transportation

Paketleme ve Nakliye

Fabrika Avantajları

Experience accumulation, focus on professionalism:

GFM excavator idler suppliers has been focusing on the manufacture of engineering machinery accessories, especially track undercarriage system components (idlers, rollers, sprockets, drive gears, etc.) for more than 15 years. We have served thousands of end users and dealer partners around the world and accumulated valuable experience in handling various complex working conditions and customized needs.

Advanced equipment, solid quality foundation:

When you walk into our production workshop, you can see real “hard guys”:

- Large-tonnage forging equipment: Ensure that the blank is dense and defect-free inside, laying the foundation for high strength.

Fully automatic CNC machining center (CNC): Achieve stable and efficient processing of complex shapes and high-precision dimensions. - Precision grinder: Perform micron-level finishing on key mating surfaces to ensure smoothness and size.

- Computer-controlled heat treatment production line & medium frequency quenching equipment: Precisely control temperature, time, and cooling speed to ensure that material performance meets standards and is stable, and each furnace has records and traceability.

- Professional dynamic balancing tester: For high-speed rotating parts, we perform strict dynamic balancing correction to eliminate vibration hazards and run more smoothly and quietly.

Quality inspection is like a mountain, and data speaks:

Quality is not a slogan, but an action that runs through every step. From spectral analysis of incoming raw materials (to ensure that the material composition is qualified), to 100% online detection of dimensions during processing, to piece-by-piece hardness testing after heat treatment, and high-precision three-coordinate measurement (CMM) sampling of finished products, we have built multiple lines of defense. The pass rate of key dimensions and performance parameters has been stable for a long time at more than 99.5%, which is the source of our confidence. All test data are recorded and archived to ensure traceability.

2011 yılında kurulan Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, ekskavatör ve buldozer yedek parçalarında uzmanlaşmış deneyimli bir üreticidir. Bu parçalar arasında şasi parçaları (palet silindirleri, taşıyıcı silindirler, dingil makaraları, zincir dişlileri, palet pabuçları, palet zincirleri, palet grupları), cıvatalar, somunlar, pimler, burçlar ve daha fazlası yer almaktadır. Piyasadaki çoğu marka ve modele uygun geniş bir parça yelpazesini kapsıyor ve stoklarımızda bulunduruyoruz. Uyumlu markalar arasında Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG vb. yer almakta olup, piyasadaki ana akım markaları kapsamaktadır.

SSS

Deneyimli bir üreticiyiz. Fabrikamız Quanzhou Şehri, Xiamei Kasabası'nda bulunmaktadır. Ziyaretiniz memnuniyetle karşılanacaktır.

Lütfen bize doğru makine modelini, parça numarasını veya bazı teknik özellikleri belirtin. Standart ürünler değilse, lütfen çizimleri sunun.

Biz genelde T/T'yi kabul ediyoruz; diğer şartlar müzakere edilebilir.

Elbette yapabilirsiniz. OEM hizmeti veriyoruz. Numuneleriniz veya çizimleriniz varsa ve toplu sipariş talep ediyorsanız, ürünleri özelleştirebilir ve profesyonel teknik destek sağlayabiliriz.

GFM, eksiksiz bir kalite, çevre ve güvenlik kontrol sistemi kurmuştur. Her parça, dağıtımdan önce titiz testlerden ve kalite kontrol önlemlerinden geçer. Fabrikamız, üretim süreçlerinde sıkı güvenlik standartlarına ve çevre düzenlemelerine uymaktadır.

ŞİMDİ TEKLİF İSTEYİN

İlgili ürünler

- ALT TAKIM

Buldozer Palet Grubu Üreticisi

- ALT TAKIM

High Quality Bottom Roller Manufacturer