Ekskavatör track assembly are an important part to ensure the stability and working efficiency of the excavator. However, many operators and equipment managers often encounter the problem of track falling. This will not only affect the working efficiency of the excavator, but may also cause equipment damage and increase maintenance costs.

Common causes of excavator track assembly falling

Insufficient track tension

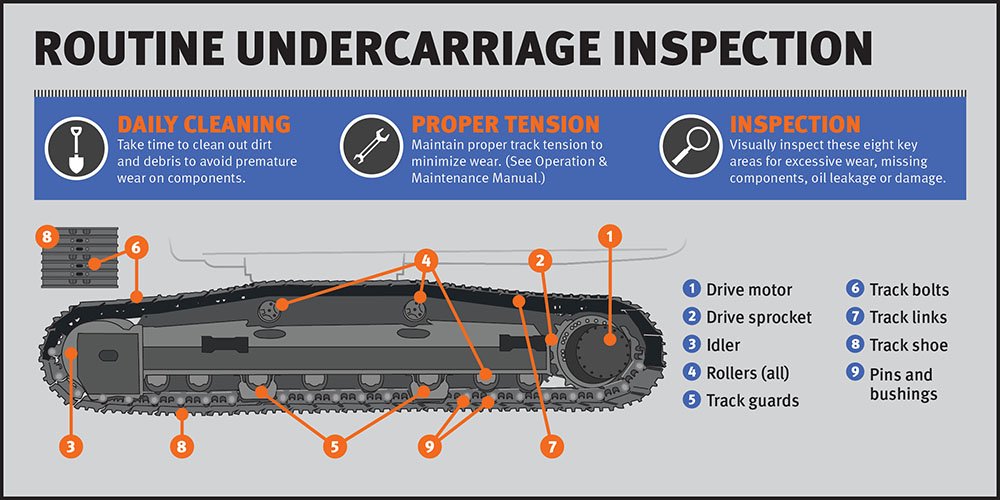

The tension of the track is crucial to its stability. If the tension is insufficient, the track may fall off due to looseness. Too little tension will cause the track to be too loose and easy to derail or fall off. Regularly checking the tension of the track and adjusting it according to the tensioning standard recommended by the manufacturer can effectively prevent this problem from occurring.

Severe track wear

With the use of the excavator, the track will wear, especially the contact surface of the track and the friction part of the ground. When the wear is severe, the track is easy to lose grip and fall off. Regularly checking the wear of the track and replacing the worn track in time can extend the service life of the track and reduce the risk of falling.

Bad road conditions

Harsh working conditions, such as soft mud, sand, or uneven rocky ground, can increase track wear and make the track more likely to fall off. Especially on soft ground, the track has poor grip and is prone to derailment. In this case, using a more suitable track type or regularly clearing ground debris can effectively alleviate the problem.

Improper operation

Improper driving operations, such as sharp turns, excessive acceleration, or sudden braking, may cause excessive external force on the track, increasing the risk of falling off. In addition, long-term high-speed driving may also increase the load on the track, causing it to fall off. Operators should be trained regularly to master the correct operating methods and avoid frequent large-scale steering or emergency stops.

Track idler or bottom roller failure

In the track system, the track idler and bottom rollers play the role of guiding and supporting the track. If these components fail or are damaged, the track may be misaligned, resulting in a fall. Regularly checking the condition of the guide wheels and support wheels to ensure that they are working properly is the key to preventing the track from falling off.

How to prevent the track assembly from falling off

Regular inspection and maintenance

Regularly check the track, tensioning system, guide wheel, support wheel and other components to ensure that there is no looseness or damage, and adjust the track tension in time to prevent the track from falling off due to excessive looseness. In addition, regularly replace the severely worn track to reduce the risk of falling off.

Choose the right track type

Choose the right track type according to the working environment. For example, when working on muddy or sandy ground, choose a track suitable for soft soil, which can enhance the track’s grip and reduce the possibility of derailment. The use of high-strength and wear-resistant track materials can also increase the service life of the track.

Control operation method

The operator should avoid violent driving operations such as sudden acceleration, sharp turns or sudden stops to ensure smooth operation. Correct driving skills can not only improve work efficiency, but also extend the service life of the track and reduce the risk of track falling off.

Regularly replace and maintain track idler and bottom rollers

The normal operation of track idler and bottom rollers is the guarantee of the stability of the track system. Regularly check the working condition of these parts to ensure that they are not loose or damaged, and repair or replace them in time to ensure the smooth operation of the crawler.

| Hızlı ve ücretsiz bir teklif alın | E-posta: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Excavator track falling off is a common maintenance problem, but with proper operation and regular inspection and maintenance, the occurrence of this phenomenon can be greatly reduced. By choosing the right crawler type, adjusting the crawler tension, and controlling the driving operation, you can ensure the stability of the excavator crawler, improve work efficiency, and reduce maintenance costs. We recommend regular cooperation with a professional equipment maintenance company to keep your equipment in the best condition.