Track assembly is an important part of excavators and bulldozers, and its performance directly affects the working efficiency and service life of the equipment. As a GFM excavator track assembly manufacturer, we are well aware of the importance of high-quality track assembly for mechanical equipment.

Composition and characteristics of track assembly

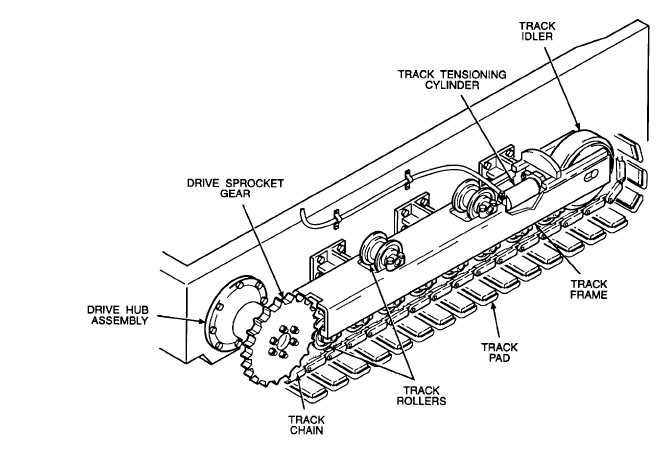

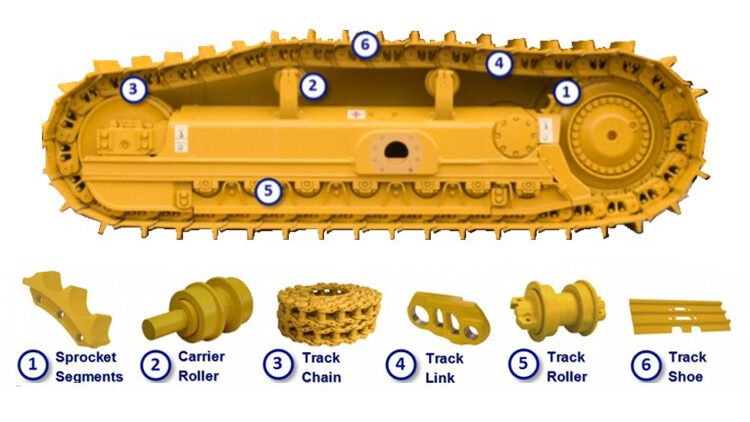

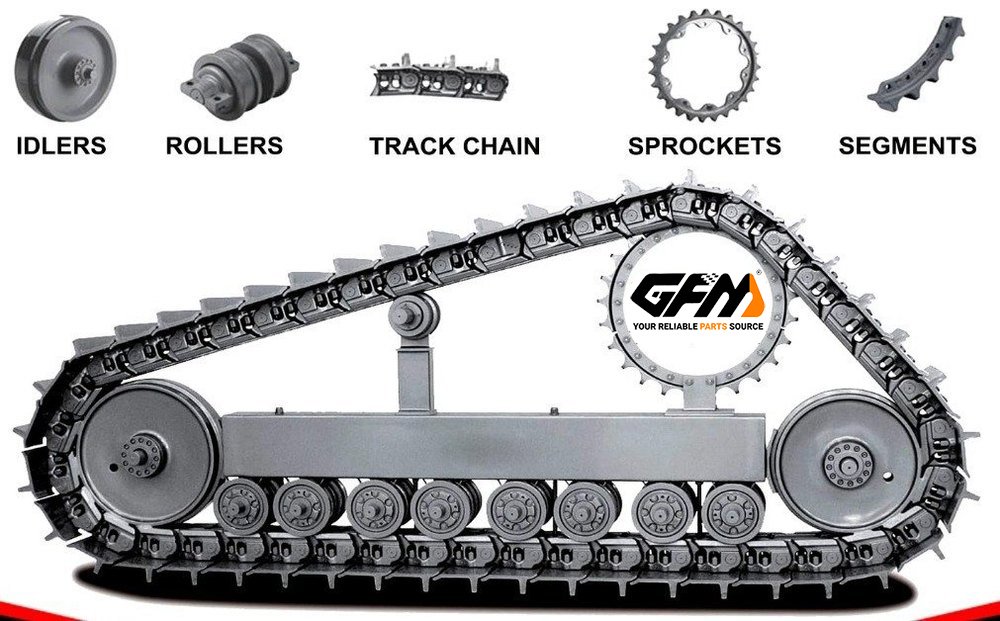

The track assembly is mainly composed of the following key parts:

- Track chain: It is composed of multiple chain links (or chain links) connected by pins. The chain is the core part of the track assembly, which is responsible for carrying the weight of the equipment and cooperating with the drive wheel to realize the movement of the equipment.

- Track shoe: It is installed on the chain link, in contact with the ground, and provides traction and stability for the equipment to move. Chain plates can be divided into ordinary type, wear-resistant type, anti-skid type, etc. according to the working environment.

- Drive wheel: It engages with the chain to transmit the power of the engine to the track, so that the equipment moves forward or backward.

- Idler wheel: It is installed at the front end of the track to guide the chain to run smoothly and prevent deviation.

- Support sprocket: distributed on the chassis of the equipment, used to support the crawler, prevent the chain from sagging and reduce wear.

- Tensioning device: adjust the tightness of the crawler to ensure that the crawler is always in a suitable state to prevent chain derailment or excessive wear.

Features:

- Strong load-bearing capacity: the design of combining chain and chain plate ensures that the equipment can adapt to heavy-load conditions.

- Diversified adaptability: According to different working conditions, the crawler assembly can be customized with different chain plates and chain track segment materials to meet complex operation requirements.

- High wear resistance: The chain track segment and chain plate are made of wear-resistant steel, which greatly extends the service life.

- Easy maintenance: modular design, easy to disassemble and replace parts.

Assembly steps of track assembly

The assembly process of the crawler assembly must be carried out in strict steps to ensure the safety and stability of the equipment.

Preparation:

- Count all track assembly parts to ensure that the chain, chain plate, drive wheel and other accessories are complete and undamaged.

- Prepare necessary tools and lubricants.

Chain assembly:

- The pins of the chain are installed one by one with the chain track segments to ensure that each connection point is tight and seamless.

- Check whether the chain pitch is consistent to avoid looseness or jamming.

Chain plate installation:

- Fix the track plate to the chain track segment by bolts or welding to ensure that each chain plate is firmly installed and evenly positioned.

- Select the appropriate type of chain plate according to the working conditions to ensure traction and wear resistance.

Drive wheel and guide wheel installation:

- Ensure that there is no deviation when the drive wheel is engaged with the chain, and perform a rotation test after installation.

- The position of the guide wheel should be adjusted strictly according to the design requirements to ensure smooth operation of the crawler.

Sprocket wheel and tensioner installation:

- The distribution of the sprocket wheels should be even to ensure that the chain does not sag during operation.

- Adjust the tensioner to make the chain tight and avoid excessive tension or relaxation.

Trial operation and inspection:

- Start the equipment slowly and observe the operation of the crawler.

- Check for abnormal noise or jamming to ensure smooth operation after assembly.

Precautions during assembly

- Component quality: give priority to chains and chain plates made of high-strength and wear-resistant materials to ensure reliable overall performance.

- Cleaning and lubrication: remove the sand and oil on the surface of all components before assembly, and fully lubricate the pins and rolling parts after assembly.

- Accurate alignment: the meshing points of the chain, drive wheel and guide wheel must be accurately aligned to avoid uneven force causing increased wear.

- Moderate tension: the tensioning device must be adjusted appropriately. Too tight will easily increase component wear, and too loose may cause the track to fall off.

Daily maintenance and care of the track assembly

Daily maintenance of the track assembly can significantly extend its service life, mainly including the following aspects:

Cleaning and inspection:

- Remove foreign matter such as soil and gravel from the track after each operation to avoid component wear caused by accumulation of foreign matter.

- Regularly check whether the chain pitch is normal and whether the chain plate has cracks or breaks.

Lubrication and maintenance:

- Add lubricating oil to the pins, drive wheels and sprocket wheels every week to ensure smooth operation of the components.

- Choose lubricants suitable for the working conditions to avoid parts jamming due to poor lubrication.

Wear replacement:

- Regularly check the wear of the chain track links and chain plates, and replace the worn or deformed parts in time.

- Check the meshing of the drive wheel and the chain, and deal with any abnormalities immediately.

Tension adjustment:

- According to the equipment use conditions and the state of the crawler assembly, adjust the tensioner in time to maintain the best working condition.

GFM track assembly core advantages

- High-quality materials: GFM crawler assembly uses high-strength wear-resistant steel to ensure the long-term durability of the chain and chain plate.

- Precision manufacturing process: Using advanced production equipment and strict quality control to ensure product accuracy and consistency.

- Diversified specifications: Covering a variety of models and sizes of chains and chain plates, suitable for different models of excavators and bulldozers.

- Professional technical support: Provide professional assembly guidance and after-sales service to ensure that customers have no worries.

- Customized service: Tailor the crawler assembly according to customer needs to meet the requirements of specific working conditions.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |