In the construction and mining industries, excavators are indispensable heavy machinery. Their stability, durability and efficient performance often depend on the quality and maintenance of undercarriage parts. Understanding the working principle of excavators and their different working parts is the key to ensuring the safety and work efficiency of construction workers.

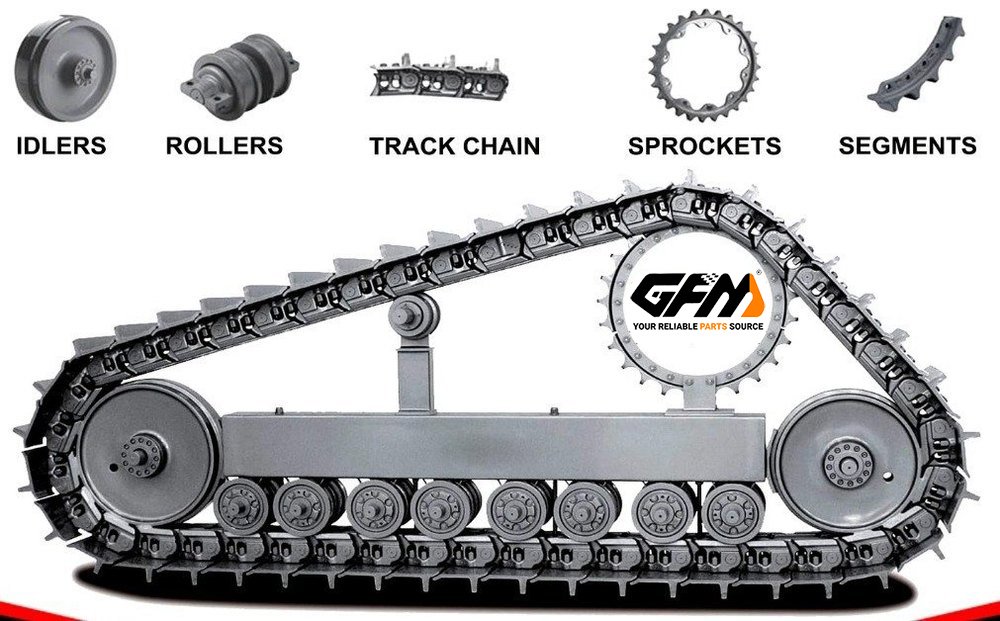

1. Excavator undercarriage parts and functions

The excavator undercarriage parts of multiple key components, each of which has its own unique function and works together to ensure the stable operation of the equipment. The following are the main parts of the excavator chassis and their functions:

1.1. Track assembly

The track assembly is one of the core components of the excavator chassis, carrying the weight of the machine and providing stable support. The track assembly includes track shoes, track chains, track rollers and drive wheels. The design of the track enables the excavator to walk on different types of ground, whether it is hard ground, muddy ground or mountainous ground.

· Track shoe

The track shoe is the external part of the track, which is in direct contact with the ground and provides the friction required for the machine to walk. Track shoes are usually made of high-strength steel or alloy. Common designs include spiked, smooth, and anti-skid patterns to suit different working environments.

· Track Chain

The track chain is the skeleton of the track system and is responsible for connecting the track shoes to the drive unit. The track chain is made up of multiple metal links and has extremely strong tensile strength and wear resistance.

· Drive Sprocket

The drive wheel transmits power from the engine and drives the track forward by meshing with the track chain. The design of the drive wheel is critical and is usually made of highly wear-resistant materials to ensure stability under high loads.

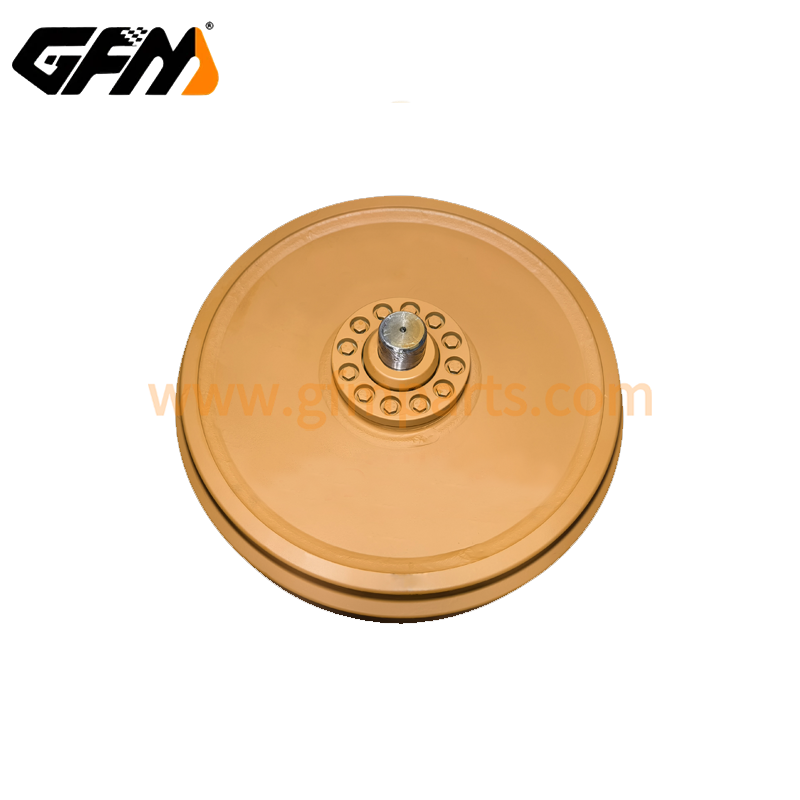

· Idler Wheel

The guide wheel is located at the front or rear end of the track and is used to guide the tension of the track and ensure its smooth operation. The guide wheel is usually equipped with a sealing device to prevent dust and debris from entering and keep it running smoothly.

· Track Roller

The main function of the track roller is to support the track chain and ensure that the track is in the correct tension state. The support roller also helps to disperse the weight of the machine, reduce the pressure on the ground, and reduce the wear of the track.

· Track Tensioner

The tensioner is used to adjust the tension of the track to ensure that the track system is moderately tight and avoid excessive wear caused by loosening or over-tightening of the track.

1.2. Drive System

The drive system is responsible for transmitting power from the engine to the chassis and controlling the movement of the excavator. This system includes a drive motor, a reducer, and a transmission chain to ensure that the excavator can travel smoothly on different terrains.

· Drive Motor

The drive motor is the core of the power system, usually a hydraulic motor or an electric motor. The hydraulic drive motor relies on the pressure of the hydraulic oil to drive the chassis to rotate, while the electric drive motor is driven by electrical energy. It converts the power of the engine into mechanical energy to drive the track forward.

· Reducer

The reducer is used to reduce the speed of the drive motor and convert it into a torque suitable for the movement of the track. The gear system of the reducer adjusts the transmission ratio through the gear ratio to ensure the smoothness and efficiency of the mechanical transmission.

· Drive Shaft

The drive shaft is responsible for transmitting power from the engine to the drive motor through the transmission system. It is usually made of high-strength steel and can withstand large torque and pressure.

1.3. Support Wheels and Rollers

Support wheels and rollers support the track and distribute the weight of the machine, helping to reduce pressure on the ground. Their normal operation helps reduce wear on the machine and improves mobility.

· Support Wheels

Support wheels are mainly responsible for supporting the inner side of the track chain to ensure smooth operation of the track. They are generally designed with wear-resistant materials and seals to prevent dust, moisture and dirt from entering, thereby reducing wear.

· Track Roller

The support wheel is one of the main components that support the track and is located below the track chain. They help distribute the weight of the machine to the track system, reduce pressure on the ground, reduce wear on the track, and also help improve the travel efficiency of the equipment.

1.4. Steering Mechanism

The steering mechanism of the excavator includes a swing drive and a steering gear, which allows the machine to achieve flexible steering movements and ensures easy operation in narrow spaces.

· Swing Drive

The excavator chassis can rotate, which is powered by a swing drive. The swing drive usually uses a hydraulic motor, which works closely with the hydraulic system to achieve smooth and precise rotation.

· Steering Gear

The steering gear is used to convert the operator’s steering instructions through the joystick or steering wheel into mechanical actions to control the rotation of the excavator. The steering gear system is usually combined with a hydraulic system to make operation easier and more precise.

1.5. Suspension System

The suspension system consists of multiple shock absorbers, springs and connectors, which absorb shocks and reduce mechanical vibrations. This is very important for equipment that runs for a long time, and can improve the stability and controllability of the machine.

· Shock Absorbers

The function of shock absorbers is to absorb the impact caused by uneven ground. They are usually hydraulic and can effectively alleviate mechanical vibrations and ensure the smooth operation of the machine. A good shock absorption system can also reduce the wear of chassis components.

· Springs

Springs play a role in the suspension system in conjunction with shock absorbers, providing continuous elastic support. They help balance the weight distribution of the machine and absorb shocks through elastic deformation.

· Linkages

Linkages connect the various components of the suspension system to each other, ensuring the stability of each component during operation. They are usually made of high-strength steel, and wear resistance and strength are very important.

1.6. Other auxiliary systems

In addition, the excavator chassis may also be equipped with other auxiliary systems, such as:

- Cooling system: Prevent chassis components from malfunctioning due to overheating.

- Lubrication system: Regularly inject lubricating oil into all moving parts to reduce friction and wear.

- Sealing system: Effectively prevent dust, moisture and other foreign substances from entering, keep components clean and extend service life.

2. Working principle of excavator undercarriage part

The working principle of the excavator undercarriage mainly depends on the synergy of its core components. The track assembly, drive system, support wheels, etc. cooperate with each other through the mechanical transmission system to ensure that the equipment can continue to operate in a complex working environment.

The tracks and drive system work together to provide the excavator with power and mobility. The drive system drives the tracks through the output power of the engine, and travels on the ground through the friction of the tracks.

The steering mechanism relies on hydraulic system control, allowing the operator to perform precise steering control through the joystick or pedals.

The cooperation of the suspension system and the support wheels ensures that the excavator travels smoothly on rugged terrain while reducing the wear and tear on the chassis.

3. Maintenance tips for excavator undercarriage parts

The excavator undercarriage parts are under great pressure and wear, so regular maintenance and care are essential. Here are some practical maintenance tips to help extend the service life of the excavator chassis and keep it in optimal working condition.

- Regularly check the track assembly: The track is one of the key components of the excavator. Regularly check whether the track is cracked, worn or loose, and replace the damaged track in time to avoid secondary damage to other components.

- Check the drive system: It is very important to replace the oil and clean the filter of the drive system. Regularly check the viscosity and cleanliness of the oil to ensure smooth operation of the drive system and reduce unnecessary friction and heat accumulation.

- Lubricate the support wheels and rollers regularly: The support wheels and rollers are easily worn parts in the excavator chassis. Regularly add lubricating oil to reduce wear and increase the service life of the parts. Check whether they rotate smoothly and replace them if necessary.

- Clean the steering mechanism: If the steering mechanism is not cleaned for a long time, it is easy to accumulate dust and dirt, resulting in inflexible steering. Clean the steering gear and hydraulic system regularly to ensure the accuracy of steering.

- Check the suspension system: The shock absorbers and springs of the suspension system should be checked regularly for aging or damage. Failure of the shock absorber will cause excessive vibration of the excavator during operation, affecting the stability and operating efficiency of the equipment.

- Check the ground adaptability: The chassis of the excavator adapts to different working grounds, so regularly check whether the machine is suitable for the working ground. If working on soft ground, use suitable track shoes to reduce sinking and damage.

The quality and maintenance of the excavator undercarriage parts are key factors to ensure the long-term and efficient operation of the equipment. Through regular inspection and scientific maintenance, equipment failures can be significantly reduced, its service life can be extended, and work efficiency can be improved. As a excavator undercarriage parts supplier, GFM is always committed to providing customers with high-quality, durable parts and providing you with professional maintenance advice to ensure that your excavator always maintains the best working condition.

If you have any needs for excavator undercarriage parts, please contact us for more professional consultation and services. We provide high-quality undercarriage parts to help your equipment achieve longer stable operation.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |