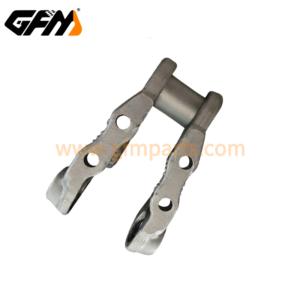

Wholesale Track Link Assembly Track Link Bush EX100/PC120(51x34x125)

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

GFM specializes in high-quality track link assembly manufacturing and supply, especially for EX100/PC120 models of Track Link Bush (51x34x125). Our products are carefully designed and strictly manufactured to ensure that every component meets the stability and durability requirements of construction machinery under high-load conditions.

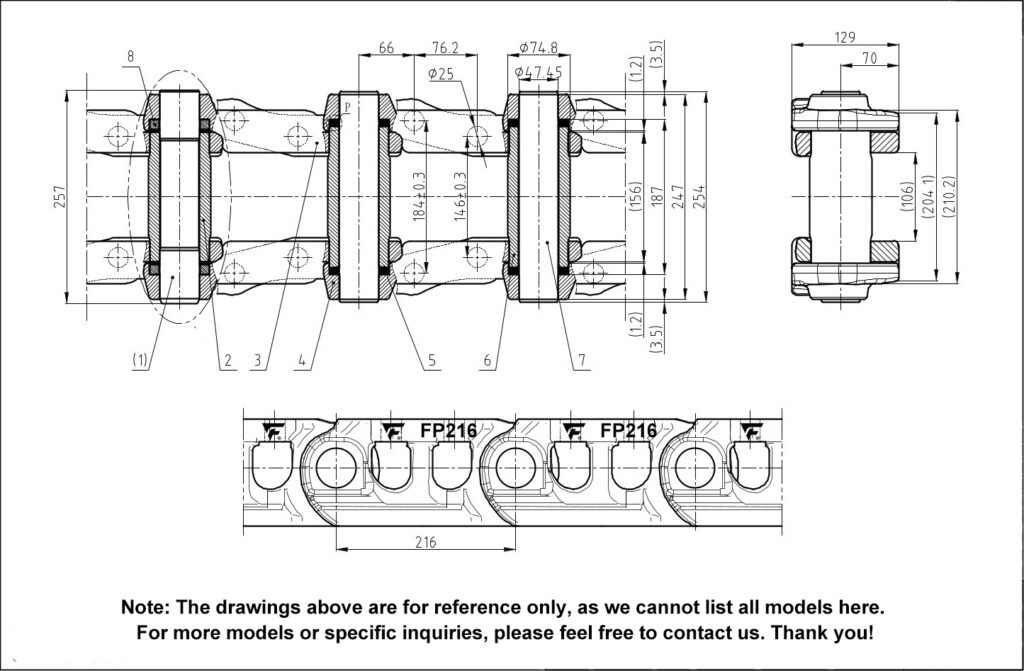

High-Quality Materials and Durability: Our track link assembly uses selected high-strength steel and undergoes precise heat treatment to enhance wear resistance and impact resistance. The fit of track pin holes, bushings, and sleeves meets strict tolerance standards, ensuring smooth operation after assembly, reducing friction and wear. Every Track Link Bush is dimensionally checked and hardness-tested to ensure components meet international standards and provide reliable load capacity for equipment.

High-Precision Design and Easy Installation: Each track link assembly is designed to balance strength and operational convenience. The component structure makes installation and removal easier, saving maintenance time. Operators can quickly complete track system maintenance, improving overall work efficiency while reducing equipment downtime risk.

Corrosion Resistance and Environmental Adaptability: The product surface is professionally treated for corrosion resistance, maintaining long-term stability even in high humidity, muddy, or corrosive environments. Each track link assembly undergoes strict factory inspection, including dimension checks, wear resistance tests, and assembly simulation tests, ensuring every set meets high-quality standards.

Reliability and Long-Term Performance: GFM’s track link assembly maintains stable performance in complex terrains and long-term continuous operation, reducing equipment failure downtime and improving project efficiency. Our products are not only durable but also effectively extend the service life of machinery, allowing customers to work with more confidence and efficiency.

Product Description

- Technique: Forging

- Raw Material: 35MnBH/40Mn2

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- High Durability– Built with premium alloy steel to withstand heavy use.

- Perfect Fit– Precision-crafted for seamless compatibility with major excavator brands.

- Enhanced Strength– Heat-treated for superior hardness and wear resistance.

- Corrosion Resistant– Special coating protects against rust in tough conditions.

- Smooth Operation– Low friction design ensures quiet and efficient performance.

- Quick Installation– Easy to assemble, saving time and reducing downtime.

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

As a professional track link assy factory, GFM has 15 years of manufacturing experience, focusing on producing undercarriage components for excavators and bulldozers, providing high-quality and reliable track link assembly to customers worldwide. Our factory strengths are reflected in the following aspects:

Rich Manufacturing Experience: Since its establishment in 2011, GFM has focused on undercarriage components manufacturing, accumulating 15 years of extensive industry experience. Whether it is rollers, idlers, guide wheels, sprockets, or track shoes, track chains, and track assemblies, we provide high-precision, durable parts to meet the needs of various construction equipment.

Modern Production Facilities: GFM’s factory covers 25,000 square meters, equipped with advanced machinery and automated production lines, including CNC machining centers, heat treatment furnaces, casting and forging equipment, ensuring high precision and durability of each part. The factory can handle bulk orders and customized projects, with a daily production capacity of hundreds of sets of track link assembly, supporting both small-batch customization and large-scale supply.

Strict Quality Control: We are equipped with coordinate measuring machines, hardness testers, and wear testing machines to rigorously inspect each batch, including dimensions, hardness, and wear resistance. Every Track Link Bush (51x34x125) is precisely checked to ensure that the shipped products meet international standards and come with at least one year or 2000 hours quality warranty.

High-Performance Process and Materials: GFM carefully selects high-quality steel and applies casting and forging combined with full heat treatment to enhance hardness, wear resistance, and impact resistance. The products remain durable under harsh construction conditions, reducing equipment downtime and improving overall project efficiency.

Wide Compatibility and Extensive Inventory: Our parts are compatible with mainstream market brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, SANY, Liugong, XCMG, Shantui, etc. With ample stock covering multiple models and specifications, we can quickly meet customer procurement needs.

Competitive Pricing and Stable Supply: 100% factory price, highly competitive in similar products. With stable production capacity and a complete management system, GFM ensures long-term stable supply, becoming a trusted partner for customers.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Wholesale PC100-5 Excavator Chain Link Loose Link

- UNDERCARRIAGE

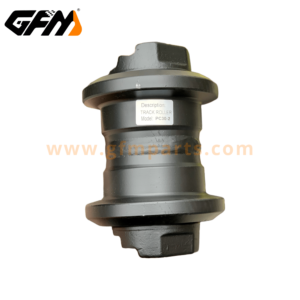

PC30-2 Bottom Roller Excavator Track Roller Manufacturer

- UNDERCARRIAGE

Top Roller Excavator Carrier Roller Factory

- UNDERCARRIAGE

High Quality Bottom Roller Manufacturer