Wholesale PC100-5 Excavator Chain Link Loose Link

- Product Quality Guaranteed

- Large Supply

- Competitive Pricing

- Most Makes & Models

- Helpful Customer Service Team

- Professional Tech Support

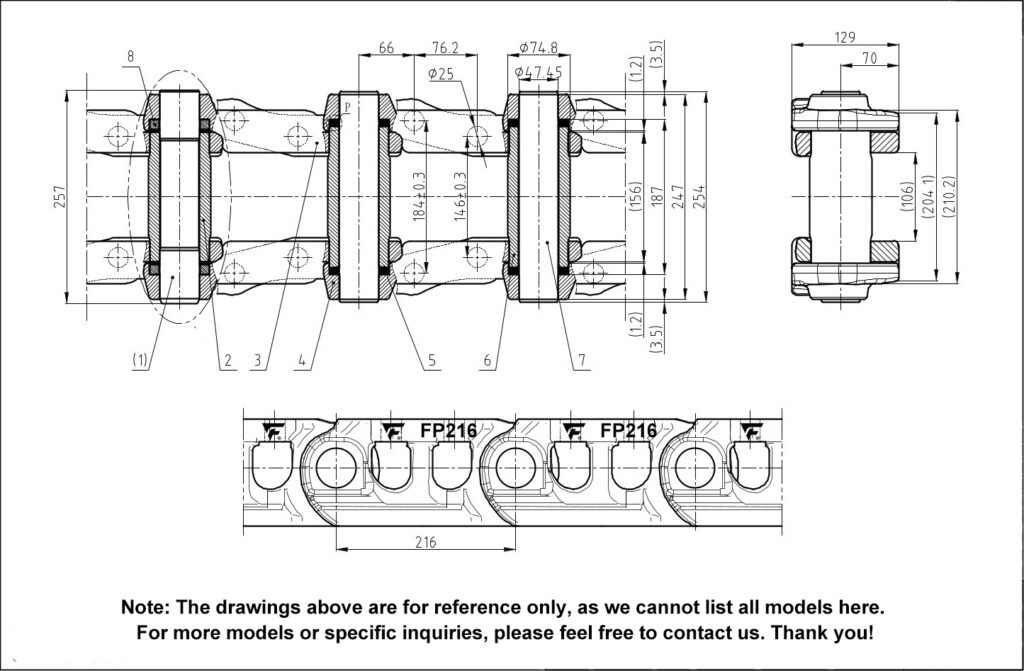

GFM focuses on the manufacturing and wholesale supply of CPC100-5 / PC100-5 excavator chain link (track chain link / Loose Link). This product is widely used in medium-sized excavator undercarriage systems and is suitable for maintenance replacement, full track assembly, and long-term high-intensity working conditions. As a track link assy supplier with 15 years of experience in excavator chain link manufacturing, GFM continuously optimizes dimensional accuracy, material stability, and service life, helping customers effectively reduce equipment maintenance costs.

- Precise Fit for PC100-5 Undercarriage Systems: GFM’s PC100-5 Track Link Loose Link is designed and manufactured strictly according to the original machine’s structural parameters. The pitch, hole spacing, link thickness, and pin hole coaxiality are precisely controlled to ensure smooth compatibility between the link, pin, bushing, and drive sprocket. During assembly and operation, this effectively reduces common issues such as “tight track” and “skipping teeth,” improving the stability and durability of the entire track system.

- High-Strength Alloy Steel Material, Balancing Toughness and Wear Resistance: The product is made of high-strength alloy steel as the base material, ensuring structural strength while maintaining impact resistance. This material is particularly suitable for PC100-5 excavators working long-term in earthmoving, gravel, and construction foundation operations. Compared with ordinary carbon steel links, its fatigue resistance and overall stability are higher, making it less prone to early cracking or deformation.

- Mature Heat Treatment Process, Extending Service Life: During manufacturing, GFM uses an overall quenching and tempering process combined with key-area reinforcement, resulting in a more uniform internal structure. Properly heat-treated links maintain sufficient toughness while significantly improving surface wear resistance. According to industry test data, properly treated track links have a wear life more than 30% longer than untreated or improperly treated products, making them ideal for long-term operation.

- Loose Link Design Suitable for Wholesale and Maintenance Markets: This PC100-5 Loose Link is designed for easy replacement and assembly, making it convenient for maintenance and wholesale purchases. Its standardized design ensures compatibility with full track assemblies and allows customers to quickly assemble or repair tracks without compromising performance.

Product Description

- Technique: Forging

- Raw Material: 35MnBH/40Mn2

- MOQ: 1 PC

- Payment Method: T/T

- Brand: GFM

- Condition: New

- Color: Yellow, Black or Customized

- Lead Time: 30 days

- Warranty: 1 Year

- Service: OEM or ODM

- Place of Origin: Fujian, China

- Application: Excavator

- Packing: Standard Export Wooden Pallet

Features

- High Durability– Built with premium alloy steel to withstand heavy use.

- Perfect Fit– Precision-crafted for seamless compatibility with major excavator brands.

- Enhanced Strength– Heat-treated for superior hardness and wear resistance.

- Corrosion Resistant– Special coating protects against rust in tough conditions.

- Smooth Operation– Low friction design ensures quiet and efficient performance.

- Quick Installation– Easy to assemble, saving time and reducing downtime.

Specifications

Product Models

Production Process

Packaging and Shipping

Factory Advantages

- Rich Manufacturing Experience: GFM has been focused on undercarriage parts production for 15 years, gaining extensive experience in manufacturing excavator chain link and related components. The team is skilled in process optimization and quality control, ensuring each product meets high standards.

- Advanced Production Equipment: Equipped with modern forging and automated machinery, GFM can produce precise and durable track links and other undercarriage components efficiently. This allows for stable supply even for bulk orders.

- Strict Quality Control: GFM implements complete quality inspection procedures. Each excavator chain link is checked for dimensional accuracy, hardness, and surface finish to guarantee optimal performance and reliability.

- Competitive Pricing and Large Supply: As a track link assy supplier, GFM provides competitive factory prices and can meet large-scale procurement needs. This ensures customers receive high-quality components without compromising cost efficiency.

- Broad Compatibility: GFM’s products are compatible with mainstream brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, Sany, Liugong, XCMG, Shantui, and more. The comprehensive selection meets diverse market demands.

- Diverse Product Selection: Main products include carrier rollers, sprockets, idlers, drive wheels, chains, track plates, bolts, bushings, bucket pins, chain pins, and chain guards, providing customers with a complete range of undercarriage solutions.

REQUEST A QUOTE NOW

Quanzhou Ganfeng Machinery (GFM Parts) Co., Ltd, founded in 2011, is an experienced manufacturer that specializes in excavators and bulldozers’ spare parts, such as undercarriage parts (track rollers, carrier rollers, idlers, sprockets, track shoes, track chains, track groups), bolts, nuts, pins, bushings and more. We cover and stock a wide range of parts applicable to most makes and models available in the market.The compatible brands include Komatsu, Hitachi, Carter, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kato, Sumitomo, Yuchai, Takeuchi, Sanhe Intelligent, Mitsubishi, Lonking, Liugong, XCMG, etc., covering the mainstream brands on the market.

FAQ

We are an experienced manufacturer. Our factory is located in Xiamei Town, Quanzhou City. Your visit is very welcome.

Please provide us the correct machine model, part number, or some specifications. If they are not standard items, please offer the drawings.

We usually accept T/T; other terms can be negotiated.

Of course, you can. We provide OEM service. If you have samples or drawings along with a mass quantity request, we can customize the goods and offer professional tech support.

GFM has established a complete quality, environmental, and security control system. Every part undergoes rigorous testing and quality control measures before distribution. Our factory adheres to strict safety standards and environmental regulations in the manufacturing processes.

REQUEST A QUOTE NOW

Related products

- UNDERCARRIAGE

Bulldozer Swamp Track Shoe Supplier

- UNDERCARRIAGE

High Quality Excavator Track Chain Manufacturers

- UNDERCARRIAGE

Wholesale Excavator Track Group Assembly Manufacturer